カタログ

Air purifier filter clogging directly affects equipment purification efficiency. Traditional manual inspection methods have high costs and inspection difficulties. Digital differential pressure sensors achieve automatic filter status determination by monitoring inlet-outlet pressure differences with ±1% accuracy.

1. Core Technical Principles of Filter Clog Detection

1.1 Pressure Differential Measurement Fundamentals

Air purifier internal fans continuously draw external air for purification processing. Under normal operation, stable pressure differences exist between inlet and outlet ports. When filter surface dust gradually accumulates, airflow resistance increases correspondingly, causing noticeable pressure differential changes.

1.2 MEMS Technology Application Advantages

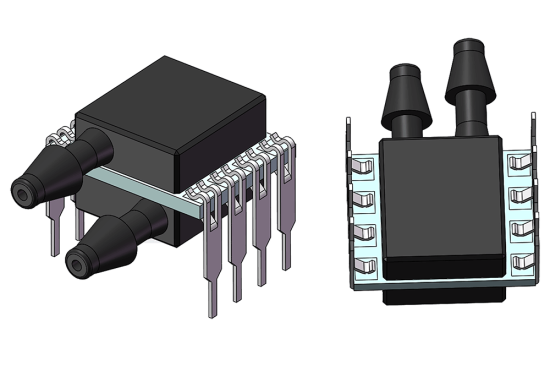

MEMS-manufactured digital differential pressure sensors use silicon-based micromechanical structures with excellent measurement precision and long-term stability. Internal integrated piezoresistive sensing elements convert minute pressure changes into precise digital signal outputs.

1.3 Real-time Monitoring and Warning Systems

Digital differential pressure sensors feature 2KHz high-frequency measurement update capabilities for continuous tracking of filter pressure change trends. When detected pressure differences exceed preset thresholds, systems immediately generate warning signals.

1.4 Digital Interface Integration Convenience

Sensors use standard I2C digital communication protocols for simple, direct connections with main controllers. Digital output characteristics eliminate analog signal processing complexity while significantly reducing MCU computational resource requirements.

2. Sensor Technical Specifications and Performance Features

2.1 Measurement Accuracy and Range Coverage

Digital differential pressure sensors completely cover -500 to 500 pascal ranges, fully meeting various air purifier application requirements. 16-bit digital output resolution ensures extremely high measurement precision with measurement errors controlled within ±1% across full ranges.

2.2 Environmental Adaptability and Stability

Sensors feature broad working temperature ranges, operating stably in -40 to 125 Celsius environments, meeting application requirements under different regional climate conditions. Built-in 125Hz digital low-pass filters effectively suppress external power noise.

2.3 Maintenance-free Design Characteristics

Sensors adopt fully packaged designs requiring no periodic calibration or maintenance operations. Factory completion of all necessary calibration procedures allows direct user deployment. This maintenance-free characteristic particularly suits commercial environments.

3. Air Purifier Integration Application Solutions

3.1 Hardware Installation and Connection

Digital differential pressure sensor installation implementation is relatively simple, mainly including physical installation and electrical connection steps. Sensor pressure ports connect respectively to air purifier inlet and outlet pipelines through flexible connections.

3.2 Software Algorithm Implementation

Filter condition determination based on sensor data requires scientific algorithmic models. Systems must establish accurate correspondence relationships between pressure differential values and filter clogging degrees through extensive experimental data analysis.

3.3 System Verification and Testing

Complete verification testing procedures ensure sensor system reliability and accuracy. Testing content covers pressure response characteristics under different clogging degrees, long-term working stability verification, and adaptability testing under various environmental conditions.

4. Technical Advantages and Application Effects

4.1 Filter Lifespan Management Improvement

Through continuous monitoring of actual filter working conditions, digital differential pressure sensors help users accurately determine filter replacement timing. Traditional scheduled replacement methods often involve premature replacement causing resource waste.

4.2 Intelligent Equipment Performance Adjustment

Real-time pressure data provided by sensors offers important reference bases for intelligent air purifier control. Control systems automatically adjust fan speeds and power outputs based on filter clogging degrees.

4.3 Significant User Experience Enhancement

Automated filter monitoring systems completely transform user experience modes. Users need not remember replacement schedules or regularly disassemble equipment for internal condition inspections.

5. Technical Standards and Quality Assurance

5.1 Manufacturing Process and Quality Control

Digital differential pressure sensors adopt mature MEMS manufacturing processes, completed in extremely high cleanliness wafer fabrication environments. Each production stage establishes strict quality control standards.

5.2 Interface Standards and Compatibility

Sensors strictly follow I2C / SPI communication protocol standards, ensuring good compatibility with various main controllers. Standardized electrical interface designs simplify system integration processes.

5.3 Technical Support and Service Guarantee

Comprehensive technical support systems provide users with full-service guarantees. From product selection consultation to application technical guidance, professional technical teams provide timely effective solutions.

結論

Digital differential pressure sensor applications in air purifier filter clog detection represent important progress in intelligent equipment management. Through precise pressure differential change monitoring, sensors timely discover filter blockage problems, achieving automated equipment management.

上記の紹介は、圧力センサー技術のアプリケーションの表面をなぞっただけです。私たちは、さまざまな製品で使用されているさまざまなタイプのセンサー素子、それらがどのように機能するか、そしてそれらの長所と短所を引き続き調査していきます。ここで説明する内容についてさらに詳しく知りたい場合は、このガイドの後半にある関連コンテンツをご覧ください。時間がない場合は、ここをクリックしてこのガイドの詳細をダウンロードすることもできます。 空気圧センサー製品PDFデータ。

他のセンサー技術の詳細については、こちらをご覧ください。 センサーページにアクセスしてください。