カタログ

Medical devices require pressure monitoring accuracy far exceeding industrial standards. Diffused silicon pressure transmitters, with ±0.1% FS measurement accuracy, excellent long-term stability, and biocompatibility, have become the preferred solution for medical-grade pressure monitoring.

1. Core Technical Principles of Diffused Silicon Pressure Transmitters

Silicon-Based Piezoresistive Effect and Signal Conversion

Diffused silicon pressure transmitters operate based on the piezoresistive effect of monocrystalline silicon. When the silicon diaphragm deforms under pressure, its resistance changes, converting pressure variations into linear voltage signals through a Wheatstone bridge circuit.

Modern diffused silicon processes use MEMS technology, forming strain resistors on silicon substrates through ion implantation and high-temperature diffusion. Medical-grade products typically use SOI substrates, further enhancing device interference resistance and long-term stability.

Medical-Grade Packaging and Biocompatibility Design

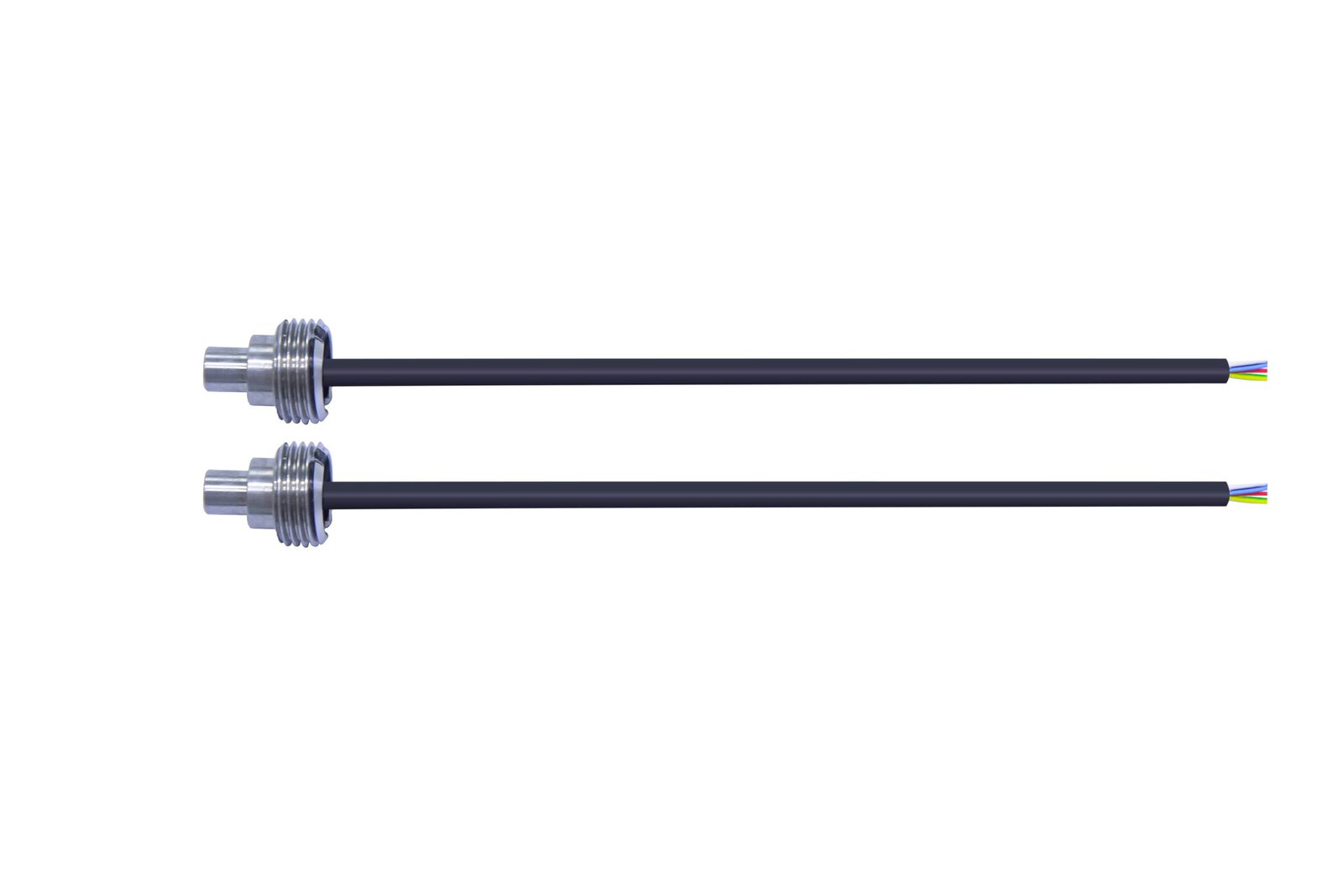

Medical applications impose strict requirements on sensor packaging. Housing materials use 316L medical stainless steel or titanium alloy, ensuring biocompatibility with human tissues. Sealing design employs laser welding, achieving IP68 protection rating and withstanding high-temperature, high-pressure sterilization.

2. Critical Applications in Life Support Equipment

Ventilator Pressure Monitoring and Control

Ventilators represent one of the most important applications for diffused silicon pressure transmitters. Sensors monitor patient airway pressure in real-time, preventing barotrauma from excessive pressure. During mechanical ventilation, systems adjust breathing parameters based on set PEEP values and tidal volumes.

Modern ventilators integrate multiple pressure sensors monitoring inspiratory, expiratory, and circuit pressures separately. The rapid response characteristics of diffused silicon sensors capture pressure fluctuations during breathing processes, providing detailed respiratory mechanics parameters.

Safety Assurance in ECMO Equipment

In ECMO devices, diffused silicon pressure transmitters monitor pressure differentials before and after blood pumps, detecting blood clot formation or circuit blockages. Medical-grade sensors ensure normal operation under extreme conditions through redundant design and self-diagnostic functions.

3. Precision Applications in Diagnostic Monitoring Devices

Technological Innovation in Blood Pressure Monitoring

Invasive blood pressure monitoring directly measures intravascular pressure through arterial catheters. The miniaturization design of diffused silicon sensors allows integration at catheter tips. Sensor diaphragm thickness of only tens of micrometers minimizes blood flow disturbance.

Modern blood pressure monitoring devices integrate intelligent algorithms that recognize arrhythmia effects on measurements and automatically adjust parameters. The linearity and repeatability of diffused silicon sensors provide reliable baseline data for these algorithms.

Precision Requirements for Intracranial Pressure Monitoring

Intracranial pressure monitoring demands extremely high sensor requirements for long-term implantation while maintaining stability. Diffused silicon sensors employ drift compensation technology, controlling annual drift within 0.1%. Sensors typically have external diameters smaller than 3mm for minimally invasive cranial implantation.

4. Safety Control in Treatment Equipment

Precise Flow Control in Infusion Pumps

Infusion pumps control liquid flow rates by monitoring circuit pressure changes. Diffused silicon pressure transmitters immediately stop infusion upon detecting pressure anomalies, preventing fluid extravasation or air embolism. Chemotherapy drug infusion requires extremely high accuracy.

Modern intelligent infusion pumps integrate pressure trend analysis functions, predicting potential problems through pressure change pattern monitoring. Continuous pressure data from diffused silicon sensors provides the foundation for predictive algorithms.

Pressure Balance Monitoring in Hemodialysis

Hemodialysis machines use multiple pressure sensors to monitor blood circuit and dialysate circuit pressure states. The reliability of diffused silicon sensors ensures safe dialysis procedures, preventing blood coagulation or circuit rupture. Precise dialysate pressure control directly affects ultrafiltration effectiveness.

5. Precision Manipulation in Minimally Invasive Surgery

Pneumoperitoneum Pressure Control in Laparoscopic Surgery

Laparoscopic surgery requires CO₂ insufflation into the abdominal cavity to create surgical space. Diffused silicon pressure transmitters monitor intra-abdominal pressure in real-time, preventing excessive pressure causing patient discomfort or complications.

Pressure Gradient Measurement in Cardiovascular Interventions

In coronary interventions, pressure wires integrate miniature diffused silicon sensors measuring pressure differentials across vessel stenoses. This measurement method accurately assesses stenosis severity, guiding stent implantation decisions. Miniaturized sensor design doesn’t affect blood flow.

結論

Diffused silicon pressure transmitters have become indispensable core components in modern medical equipment through their exceptional technical performance. High precision, reliability, biocompatibility, and miniaturization characteristics establish their important position in medical fields, providing more reliable technical assurance for patient safety and treatment effectiveness.

上記の紹介は、圧力センサー技術のアプリケーションの表面をなぞっただけです。私たちは、さまざまな製品で使用されているさまざまなタイプのセンサー素子、それらがどのように機能するか、そしてそれらの長所と短所を引き続き調査していきます。ここで説明する内容についてさらに詳しく知りたい場合は、このガイドの後半にある関連コンテンツをご覧ください。時間がない場合は、ここをクリックしてこのガイドの詳細をダウンロードすることもできます。 空気圧センサー製品PDFデータ。

他のセンサー技術の詳細については、こちらをご覧ください。 センサーページにアクセスしてください。