現代のテクノロジーおよび産業用途で, 圧力センサーは重要な測定ツールとして重要な役割を果たします. その中で, ゲージ圧力センサー, 差動圧力センサーと絶対圧力センサーは、独自の機能と幅広いアプリケーションのために、圧力測定の分野の3つのコアセンサーです。. この論文では, 定義について詳しく説明します, 運用原則, 測定オブジェクト, アプリケーションシナリオ, これらの3つのセンサーの違い.

目次

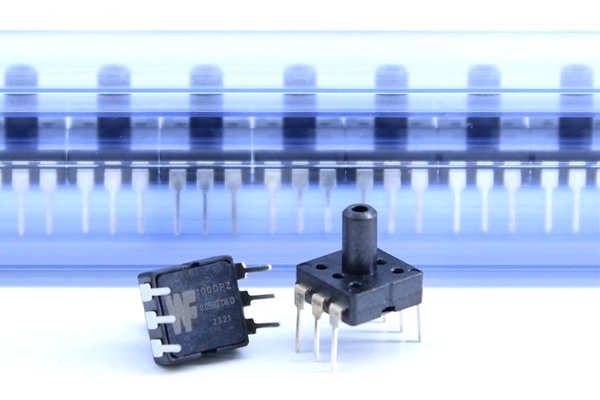

ゲージ圧力センサー

定義と操作の原則

ゲージ圧力センサーは、相対圧力を測定するセンサーです, つまり. 大気圧に対する圧力値. 通常、センシング要素で構成されています (例えば. ひずみゲージまたはピエゾレス抵抗要素) 圧力を通信信号に変換する電子回路. センシング要素に外部圧力が適用される場合, 要素は小さな変形を受けます, その結果、抵抗値が変化します, 電子回路によって測定され、圧力に関連する通信信号に変換されます.

操作原則

ゲージ圧力センサーは、大気圧に基づいています, 圧力測定値は大気圧の違いに関連しています. 例えば, センサーに値が表示された場合 5 バー, その後、実際の圧力は次のとおりです 5 大気圧よりも高いバー.

測定オブジェクトとアプリケーション

通常、相対的な圧力が必要なアプリケーションで使用されます, 水圧など, ガス圧, 液体圧力, 流体制御, レベル測定など. 例えば, 化学プラントで, ゲージ圧力センサーを使用して、パイプラインの圧力を測定して、操作が安全な制限内で実行されるようにすることができます. 自動車で, ゲージ圧力センサーは、タイヤの圧力を測定するために多くの場合使用され、ドライバーにタイヤの状態に関する情報を提供します. コンシューマーエレクトロニクスで, ゲージ圧力センサーは、圧力変化監視などの領域で使用されます, 環境適応, 健康監視. 高度測定などの重要な機能を提供します, 天気はアラートを変えます, エアフローモニタリング, 等々.

特徴:

- 大気圧の変化に基づいています.

- 大気圧が変化した場合, ゲージ圧力センサーの読み取り値は影響を受けません.

- ガスシステムなどの一般的な産業用途に適しています, 油圧システム.

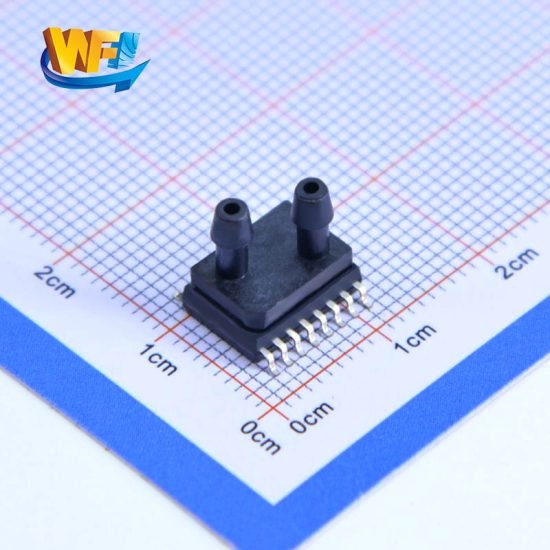

差圧センサー

定義と操作の原則

差圧センサーは、2つの測定チャンバー間の圧力差を測定するセンサーです. 2つの異なるポイント間の圧力差を測定します. 大気に対するこれらの圧力点の圧力には関係ありません, しかし、それらの違いはあります. 通常、測定する媒体に接続された2つのチャンバーで構成されています, そして、圧力はチャンバー間の圧力差を測定することによって決定されます. 微分圧力センサーの動作の原理は、センサーの横隔膜上で直接測定する圧力に基づいています, ダイアフラムが水圧に比例して微小な変動を生成するように, 抵抗の価値に変化を引き起こします, 電子回路はこの変化を検出し、圧力に対応する標準化された測定信号に変換します.

操作原則

差圧センサーは、2点で圧力を同時に測定し、それらの差を計算することにより、相対差圧の値を出力します. 例えば, パイプラインの両端で, 差圧センサーは、圧力差を測定できます, これは、フロー測定とフィルターの詰まりの検出に一般的に使用されています.

測定オブジェクトとアプリケーション

差圧センサーは、フロー測定で広く使用されています, 液体レベルの測定, ガス分析およびその他のフィールド. HVACシステムで, 差動圧力センサーは、エアフィルターの目詰まりを測定するためによく使用され、タイムリーに交換できるようにします. 加えて, また、微分圧力センサーは、車両のエンジン粒子トラップのフロントパッセージとリアパッセージ間の排気ガス圧力の違いを測定して、トラップ内の粒子蓄積のレベルを決定するためにも使用されます。, これは、「再生」のトリガー時間と注入される追加の燃料の量を決定します.

特徴:

- 2つのポイント間の圧力差を監視するのに最適です.

- フロー計算に使用されます, 風速測定, 等.

- 2つのポイント間の圧力差を比較します, 大気圧の影響を無視します.

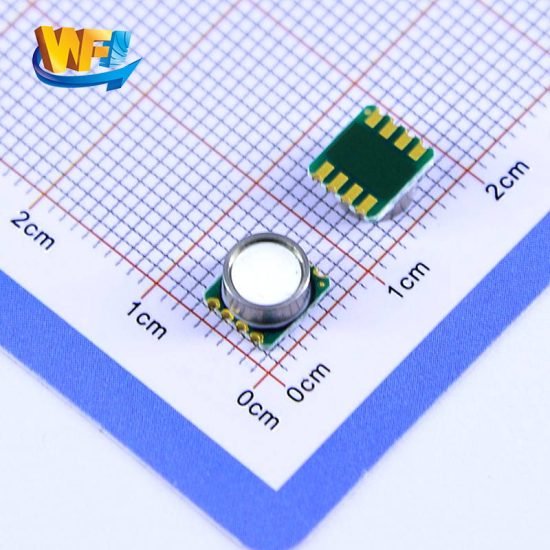

絶対圧センサー

定義と操作の原則

絶対圧力トランスデューサーは、真空または絶対ゼロに対する圧力を測定するトランスデューサーです. ゲージ圧力センサーとは異なります, 絶対圧力センサーは、測定された培地の圧力を測定するだけではありません, しかし、環境のガス圧力も考慮に入れてください. 絶対圧力センサーは、圧力センサーを測定するのと同様に機能します, しかし、それらの基準点は、大気圧ではなく絶対的な真空または絶対ゼロです. または完全に圧力のない状態の圧力. 絶対ゼロ圧力に基づいています (真空) 大気圧の影響を受けません.

操作原則

絶対圧力センサーは、ガスまたは液体の絶対圧力を測定します, そして、その読書には常に大気圧の効果が含まれます. たとえ大気圧が変化しても, 絶対圧力センサーの読み取りは絶対圧力を反映します.

測定オブジェクトとアプリケーション

絶対圧力センサーは、大気圧測定で広く使用されています, 高高度気象観察, 天気予報およびその他のフィールド. 医療分野では, 絶対圧力センサーは、呼吸器のガス圧を監視するために使用されます. 加えて, 絶対圧力センサーは、吸気気圧を測定してエンジンのパフォーマンスと燃費を最適化するためにも使用されます.

特徴:

- 真空と比較した圧力を測定します, 大気圧の変化を考慮して.

- 絶対圧力センサーの使用は、特定の環境で特に重要です, 高度の変動が高いアプリケーションなど.

- 正確な圧力監視が必要なハイエンドアプリケーションで使用されます, 航空宇宙など, 気象モニタリング, 真空技術.

3種類のセンサー間の違い

1. 測定オブジェクト:

- ゲージ圧力センサーは、大気圧に比べて圧力を測定します.

- 差圧センサーは、2つの測定チャンバー間の圧力差を測定します.

- 真空に対する圧力値を測定する絶対圧力センサー.

2. 測定原則:

- 表面圧力センサーは、絶対圧力センサーと大気圧センサーを使用して、絶対圧力と大気圧の差を計算することにより、表面圧力を測定および計算します。.

- 差圧センサー2つの圧力センサーを使用して、2つの位置間の圧力差を測定します.

- 絶対圧力センサーは絶対圧力センサーを使用して、測定結果から大気圧を測定および減算して絶対圧力を取得します.

3. 測定範囲:

- ゲージ圧力センサーには通常、測定範囲が大きく、高圧と低い圧力の両方を測定できます.

- 差圧センサーは通常、より小さな差圧測定範囲に使用されます.

- 絶対圧力センサーには、特定のアプリケーションに依存する測定範囲があります, ただし、通常、真空状態を考慮する必要があります.

4. アプリケーションシナリオ:

- ゲージ圧力センサーは、産業用自動化で一般的に使用されます, 自動車産業, 医療機器およびその他の分野.

- 差圧センサーは、フロー測定で広く使用されています, 液体レベルの測定, ガス分析およびその他のフィールド.

- 絶対圧力センサーは大気圧力測定により焦点を合わせています, 高高度の気象観測および正確な圧力測定を必要とするその他のアプリケーション.

結論

ゲージ圧力センサー, 差動圧力センサーと絶対圧力センサーは、圧力測定の分野の3つのコアセンサーです, 独自の機能と幅広いアプリケーションを備えたそれぞれ. 彼らの運営原則を深く理解することを通して, 測定オブジェクトとアプリケーションシナリオ, これらのセンサーをより適切に選択して使用して、さまざまなフィールドの測定ニーズを満たすことができます. テクノロジーが発展し続けています, これらのセンサーのパフォーマンスと精度は改善され続けます, 工業生産と科学研究のために、より信頼性の高い正確な測定データを提供する.