カタログ

理解を始めましょう!

セラミック圧力センサーの基本原理と構造

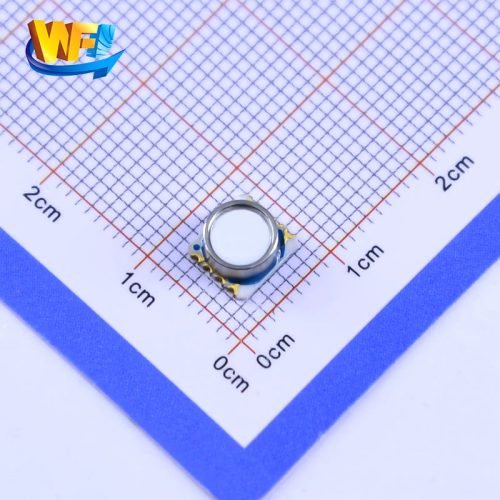

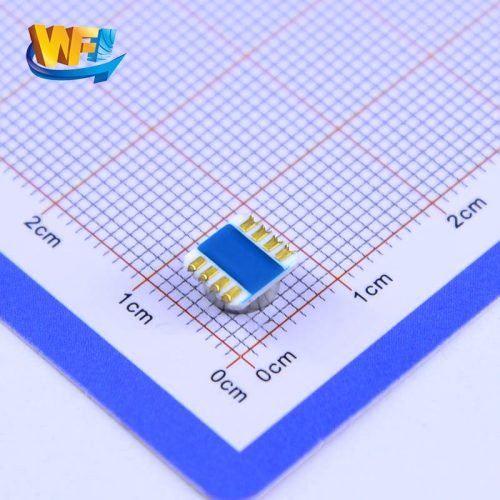

セラミック圧力センサー are mainly composed of ceramic sensitive elements, measurement circuits and signal processing units. Its working principle is based on the piezoelectric or piezoresistive effect of ceramic materials: when pressure is applied externally, the electric field or resistance within the ceramic changes, which is then converted into a measurable electrical signal. The high mechanical strength and excellent electrical characteristics of the ceramic material ensure stable operation and long service life of the sensors in high-pressure environments.

セラミック圧力センサーのセンシングパフォーマンス分析

感度

Sensitivity refers to the ability of a sensor to respond to pressure changes. Selection of ceramic materials with high pressure resistance coefficients, such as high-purity silicon or specific ceramic composites, can improve the sensitivity of the sensor. In addition, optimizing the structural design of the sensitive element, such as reducing the thickness or adjusting the geometry, can also help to increase the sensitivity.

正確さ

Accuracy reflects how close the sensor’s measured value is to the true value. Precise manufacturing processes and high-quality material selection are key to improving accuracy. Meanwhile, the use of advanced signal processing techniques, such as digital filtering and linear compensation, can effectively reduce measurement errors.

安定性

Stability refers to the ability of a sensor to maintain consistent performance over a long period of time. The thermal stability and anti-aging properties of ceramic materials allow them to perform well under temperature changes and long-term loads. However, environmental factors such as humidity and corrosive media can affect their stability and require enhanced sealing and protection designs.

直線性

Linearity describes the linear relationship between sensor output and input pressure. Precise structural design and material selection ensures that the sensor maintains good linearity over the entire measurement range. In addition, linearity correction algorithms in the signal processing circuitry can improve linearity performance.

セラミック圧力センサーの応答速度分析

センサーの構造設計

The response speed is affected by the quality and structure of the sensitive element. Reducing the thickness and mass of the sensitive diaphragm increases the response speed of the sensor. However, a balance between sensitivity and mechanical strength is needed to ensure the reliability of the sensor.

信号処理回路

Efficient signal processing circuitry is critical for fast response. The use of high-speed analog-to-digital converters (ADCs) and fast processors reduces signal transmission and processing time, thereby improving overall response.

環境要因

Environmental factors such as temperature, humidity and rate of pressure change can affect the response speed of a sensor. The effects of these factors need to be considered in the design and compensating measures, such as temperature compensation circuits and moisture-proof designs, need to be taken to ensure the sensor’s fast response in a variety of environments.

セラミック圧力センサーの最適化戦略

材料の選択を最適化します

The selection of high-performance ceramic materials, such as high-purity alumina or zirconia, increases the sensitivity and stability of the sensor. These materials have excellent mechanical and electrical properties and are suitable for high-precision measurements.

構造設計の改善

Optimizing the thickness and geometry of the sensitive diaphragm through finite element analysis ensures a balance between mechanical strength and response speed while increasing sensitivity. In addition, innovative package designs, such as the use of compression springs to realize electrode connections, improve sensor integration and reliability.

高度な信号処理技術の適用

Adopting advanced signal processing algorithms such as digital filtering, temperature compensation and linear correction can improve measurement accuracy and response speed. In addition, the integrated signal conditioning circuit design helps reduce external interference and improve signal quality.

温度と湿度の補償の向上

Changes in ambient temperature and humidity can affect sensor performance. By introducing a temperature and humidity sensor into the design, monitoring environmental changes in real time and compensating accordingly, the stability and accuracy of the sensor under various environmental conditions can be ensured.

結論

Ceramic pressure sensors are widely used in various fields due to their excellent performance. By optimizing material selection, improving structural design, applying advanced signal processing technology and strengthening environmental compensation, its sensing performance and response speed can be further enhanced. In the future, with the continuous development of new materials and technologies, ceramic pressure sensors will show their unique advantages in a wider range of applications.

上記の紹介は、圧力センサー技術のアプリケーションの表面をなぞっただけです。私たちは、さまざまな製品で使用されているさまざまなタイプのセンサー素子、それらがどのように機能するか、そしてそれらの長所と短所を引き続き調査していきます。ここで説明する内容についてさらに詳しく知りたい場合は、このガイドの後半にある関連コンテンツをご覧ください。時間がない場合は、ここをクリックしてこのガイドの詳細をダウンロードすることもできます。 空気圧センサー製品PDFデータ。

他のセンサー技術の詳細については、こちらをご覧ください。 センサーページにアクセスしてください。

Hey there, You’ve done a great job. I will definitely digg it and personally suggest to my friends.

I’m sure they will be benefited from this website.