- Oleh Sensor WF

A high-power laser focuses energy so the local material melts or vaporises, while assist gas clears the melt and shields the nozzle. Accurate pressure measurement is central to maintaining stable process control. Below we explain absolute pressure measurement, break down required components and interfaces, cover wiring and placement, and finish with reliability and industrial-grade selection criteria.

Katalog

1. The role of gas pressure in laser cutting

Laser cutting works by using a focused, high-energy beam to melt or vaporise material; the assist gas then blows the molten material away. Gas pressure directly shapes the cut surface, the heat-affected zone and cutting speed. The right pressure will swiftly remove dross and avoid splashback that could foul the nozzle or the workpiece; too much pressure can cause splatter, burrs or lateral deviation of the cut. Systems typically put sensors at the gas source and near the nozzle and use real-time pressure data to close the loop and keep each cut inside a defined process window. For production environments you need sensors that combine good resolution, sufficient sample rate and temperature compensation. Digital pressure sensors send stable data straight to the controller and cut down errors introduced by long analogue runs, improving consistency and throughput.

Cut quality and pressure control

Cut edge finish depends on a balance between laser power and the kinetic energy of the gas. Different materials and thicknesses need different pressure curves: thin sheet metal usually needs lower pressure to avoid excessive removal, while thick plate needs higher momentum to clear large volumes of molten material. Real-time pressure feedback lets the controller tweak gas flow during cutting, maintaining edge quality while keeping speed high. Locating the sensor close to the nozzle gives the truest reading of working pressure, but you must avoid placing it directly in the hot gas jet.

Equipment protection and fault response

When pressure changes suddenly — for example because of a clogged filter or pump failure — the sensor must trip protection logic fast to prevent nozzle damage or scrapped parts. Engineering practice uses threshold settings and self-test routines combined with safe shutdowns or process switches to limit loss. Sensor response time and measurement stability determine how dependable those protection scripts really are, so pick sensors with good short-term dynamics and shock resistance.

2. Absolute pressure sensor operating principles

An absolute pressure sensor measures pressure relative to vacuum. Modern devices often use a MEMS sensing diaphragm; pressure deforms the diaphragm slightly, that deformation changes an electrical parameter (capacitance or resistance) and an integrated front-end ASIC amplifies and converts that to a digital value. Absolute measurement is useful because readings aren’t skewed by ambient atmospheric changes, so you get consistent results across locations and shifts. Digital absolute pressure sensors commonly include temperature compensation and full-scale calibration, which shortens on-site setup work. For laser cutting, choose parts with wide operating temperature ranges and protective packaging so they keep steady performance in a workshop and reduce maintenance overhead.

MEMS sensing element and the signal chain

The sensing element is typically a silicon microstructure; a micron-scale membrane flexes under pressure. That mechanical change becomes an electrical signal and the ASIC handles amplification and filtering. High-integration parts store calibration coefficients on-chip so manufacturers deliver linear, low-offset sensors ready to plug in. Because cutting machines expose sensors to thermal and vibrational disturbances, built-in temperature compensation and anti-vibration design materially cut drift.

Digital outputs and measurement stability

Digital interfaces (I²C, SPI) carry high-resolution data without the noise pickup you get on long analogue runs. Many high-precision models use 24-bit converters so the controller sees fine changes. Mind the sample rate, bus bandwidth and any protocol conflicts — in fast cutting modes you don’t want data latency to bottleneck the control loop. Wider supply tolerance helps parts fit different controller boards and eases integration.

3. Key components and digital interfaces

A pressure module includes more than the sensing chip: you need front-end filtering, ADC, temperature compensation, a reliable mechanical package and robust electrical interfaces. Highly integrated digital sensors combine those functions in one package, which reduces BOM and simplifies PCB design. On laser cutters, parts that support both I²C and SPI and accept a wide supply voltage are particularly handy — they speed up integration with existing controllers and cut firmware work. For packaging, SMD-compatible compact parts let you mount close to the measurement point but ensure the gas port materials and sealing are suitable so dust or condensation can’t spoil readings.

Interface and power requirements

Pick an interface that matches your controller; if the control system uses an industrial bus, plan for bridges or gateways. A broader supply range makes a sensor more adaptable to different power architectures. Pay attention to grounding and shielding when routing cables around the laser drive and high-current switches — a solid grounding strategy reduces EMI and protects measurement accuracy.

Packaging and field immunity

Packaging needs to balance gas access and environmental protection. Small “stamp-style” packages are convenient for mounting on the same board, but the sealing surfaces must be compatible with process gases. Choose parts with IP and dust ratings suitable for the shop floor and consider physical filtration or isolation to keep particles away and extend sensor life.

4. Layout and system integration practices

Experience shows that good sensor placement and tidy electrical integration are both essential. A common layout is one sensor at the gas supply and one near the cutting nozzle, with thresholds often set around 25 bar to spot faults quickly. To reduce wiring complexity, both sensors can be mounted on the same PCB and connected to the main controller via a single cable, which simplifies manufacturing and maintenance. Integration must also allow for pipe losses, potential leaks at fittings and any delay introduced by the layout — these affect control response and measurement accuracy.

Principles for choosing sensor points

The supply-side sensor checks the general health of the gas feed; the nozzle-side sensor reflects the conditions at the workface. Avoid exposing sensors to the centre of the hot jet and account for pressure drops at elbows and fittings when you calibrate. It’s wise to record measured differences during commissioning and use those offsets in the controller so the closed-loop behaviour is predictable.

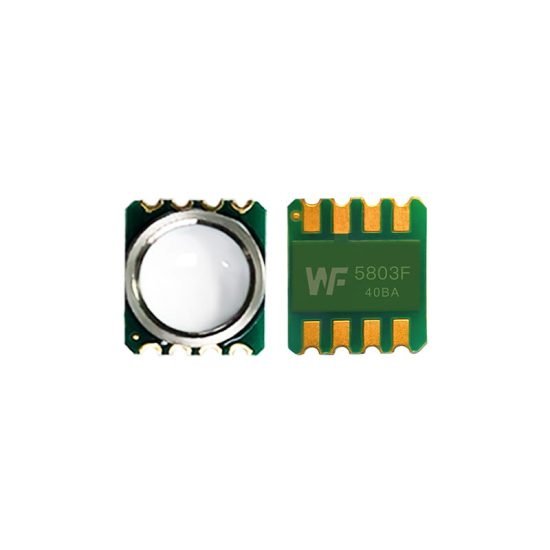

Integration tips for the WF5803F-030BA

The sensor pictured, WF5803F-030BA, offers 24-bit digital I²C/SPI twin interfaces, built-in full-scale calibration and temperature compensation, a wide operating temperature range and 1.8V–5.5V supply support. Mounting it on a board close to the nozzle lets it feed high-resolution data straight to the controller, cutting out analogue conditioning. Its SMD-6 package suits SMT assembly and reduces hand wiring, which is helpful for volume production in laser cutting equipment.

5. Reliability and industrial-grade selection

In continuous production, sensor drift, vibration tolerance and batch consistency affect maintenance costs and uptime. Prefer parts with quality system traceability and published long-term drift and accelerated-ageing data. Industrial or automotive-grade sensors go through stricter screening, so they perform better under vibration, thermal cycling and EMI. A robust diagnostic and replacement strategy lowers the chance of sudden downtime.

Drift management and lifetime assessment

Sensors can show offset changes and sensitivity drift over time. When assessing parts, ask for the vendor’s ageing curves, thermal cycle tests and long-term stability numbers. At system level, you can manage drift with software self-checks, reference-based online corrections or planned replacements. Designing for easy access and quick swaps dramatically shortens repair times and reduces lost production.

The value of industrial-grade devices

Although industrial and automotive parts may cost more up front, their consistency and reliability cut rework and downtime in high-volume lines. Digital absolute pressure parts give stable outputs and traceability that fit well with batch quality control. When choosing components, weigh total cost of ownership rather than the initial sticker price ― that often yields the best long-term outcome.

Kesimpulan

Gas pressure control in laser cutting demands fast response and long-term stability. Using digitally integrated absolute pressure sensors with temperature compensation, 24-bit output and wide power tolerance simplifies controller design and improves process consistency. Proper sensor placement, EMI-aware wiring and careful device selection are the keys to steady cut quality and low maintenance. The WF5803F-030BA typifies a compact, SMT-friendly, industrially suitable option that helps achieve dependable pressure monitoring on production lines.

Pengenalan di atas hanya sekilas tentang penerapan teknologi sensor tekanan. Kami akan terus mengeksplorasi berbagai jenis elemen sensor yang digunakan di berbagai produk, cara kerjanya, serta kelebihan dan kekurangannya. Jika Anda ingin mengetahui detail selengkapnya tentang apa yang dibahas di sini, Anda dapat melihat konten terkait nanti di panduan ini. Jika Anda terdesak waktu, Anda juga dapat mengklik di sini untuk mengunduh rincian panduan ini Data PDF Produk Sensor Tekanan Udara.

Untuk informasi lebih lanjut tentang teknologi sensor lainnya, silakan Kunjungi Halaman Sensor Kami.