Կատալոգ

Meteorological monitoring, outdoor equipment, intelligent transportation, and environmental detection increasingly rely on accurate and reliable barometric pressure sensors to obtain critical environmental data. However, these devices are often exposed to harsh climate conditions including wind, rain, high temperature, high humidity, sand erosion, and even ice and snow freezing for extended periods. Waterproof barometric pressure sensors provide essential protection for stable operation in harsh environments through excellent protective performance and environmental adaptability.

1. Core Principles and Structural Characteristics

Key Structural Design and Packaging Technology

Waterproof barometric sensors utilize fully sealed housing structures with high-strength silicone and epoxy resin sealing materials at shell joints to effectively prevent water vapor from penetrating the sensor interior. Internal MEMS chips are manufactured through precision micromachining processes, ensuring stable pressure sensing capability while maintaining micrometer-level structural precision.

Material Selection and Weather Resistance

These sensors widely adopt corrosion-resistant, UV-resistant materials such as stainless steel, PPS, and PTFE, supplemented by IP67/IP68 or higher packaging standards. Under extreme climate conditions like acid rain, high salt fog, and high humidity/temperature environments, sensors maintain long-term stable operation.

Signal Processing and Compensation Algorithms

Modern waterproof barometric sensors incorporate built-in temperature compensation circuits and digital signal processing chips, enabling real-time correction of zero drift and full-scale output changes caused by temperature variations.

2. Typical Application Requirements Under Harsh Climate Conditions

High Humidity Rain/Snow Environment Adaptability

In tropical rainforests, subtropical coastal areas, and northern ice/snow regions, sensors must withstand long-term exposure to high humidity or freezing conditions. Waterproof barometric sensors effectively solve technical challenges through high-protection housings and anti-condensation designs.

High Temperature Exposure Scenario Response

In deserts, summer high-temperature cities, or high-altitude regions where surface temperatures regularly exceed 50°C, sensors face extreme requirements for thermal stability and UV resistance. Waterproof sensors enhance heat resistance and extend equipment lifespan through high-temperature materials and reflective coating protective housings.

Strong Wind/Sand and Corrosive Atmosphere Protection

In arid, windy, dusty regions, sensors are susceptible to sand intrusion causing diaphragm wear, interface blockage, or mechanical jamming. Waterproof designs simultaneously provide dust and corrosion resistance, enabling long-cycle operation in complex atmospheric conditions.

3. Core Performance Indicators Ensuring Long-term Stability

Protection Level and Sealing Performance

Waterproof barometric sensors typically adopt IP67, IP68, or higher sealing standards, meaning they can continuously operate submerged over one meter deep for hours without functional impact while effectively blocking dust particle intrusion.

Temperature Adaptability and Thermal Stability

High-quality sensors typically accommodate temperature ranges from −40℃ to +85℃ or wider. Through internal circuit temperature compensation modules or thermal control algorithms, sensors maintain precision without drift during severe temperature fluctuations.

Anti-interference Capability and Signal Integrity

Waterproof sensors often feature EMI designs preventing signal fluctuations from lightning, radio signals, and transformer induction. Multi-layer PCB protection and surge resistance designs further enhance anti-interference and electrical strike resistance.

4. Key Application Industry Scenario Analysis

Intelligent Transportation and Meteorological Systems

Highways, bridge tunnels, and urban weather stations require 24/7 operation in wind, rain, high temperature, and high humidity open areas. Waterproof sensors monitor atmospheric pressure changes for weather prediction and flood/landslide risk warnings.

Marine and Fishery Monitoring Applications

Shipborne instruments, seabed sensor platforms, and aquaculture monitoring systems deployed in coastal or marine environments face long-term high-salt corrosion and surge impacts. Waterproof sensors ensure continuous and accurate data acquisition through high-sealing housings and corrosion-resistant electrode materials.

Smart Agriculture and Environmental Sensing

In farmlands or forest grasslands requiring long-term monitoring of pressure and climate changes for precipitation prediction and irrigation/pest control assistance, waterproof sensors resist dew, rain, snow, and animal interference as indispensable components of smart agriculture systems.

5. Technological Evolution and Development Trends

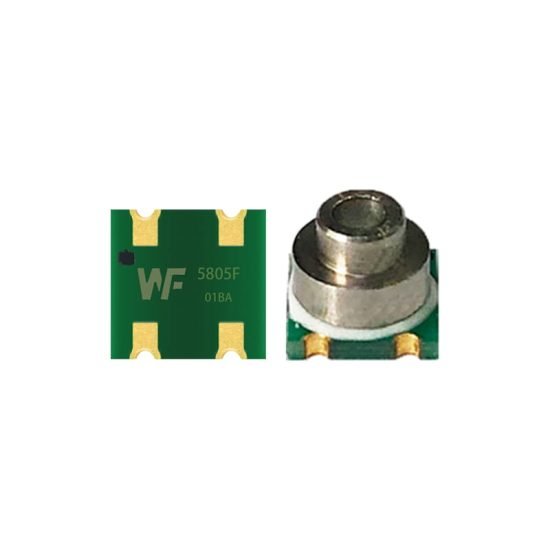

Miniaturization and Integration Development

New MEMS packaging technologies significantly reduce sensor sizes for easy integration into smaller spaces like wearable devices, smart textiles, and micro-drones. Multi-sensor fusion trends drive integration of pressure, temperature, humidity, and light sensors into single chips for comprehensive environmental monitoring.

Intelligence and Edge Computing Integration

Future waterproof sensors will incorporate local AI modules for edge recognition and early warning of abnormal pressure changes, such as pre-flood pressure anomaly warnings or high-altitude human tolerance assessments.

Material Science Innovation Applications

Applications of high-performance nanomaterials, self-healing coatings, and graphene diaphragms will further improve sensor weather resistance and lifespan, particularly in high-corrosion, strong-radiation environments.

Եզրափակում

Waterproof barometric pressure sensors, as core components of modern environmental monitoring systems, successfully address traditional sensor application challenges in harsh climate conditions through advanced packaging technology, quality material selection, and intelligent signal processing. Their excellent protective performance, stable measurement accuracy, and wide applicability make them irreplaceable in intelligent transportation, marine monitoring, smart agriculture, and other critical fields.

Վերոնշյալ ներածությունը միայն քերծում է ճնշման սենսորային տեխնոլոգիայի կիրառությունների մակերեսը: Մենք կշարունակենք ուսումնասիրել տարբեր արտադրատեսակներում օգտագործվող սենսորային տարրերի տարբեր տեսակները, ինչպես են դրանք աշխատում, ինչպես նաև դրանց առավելություններն ու թերությունները: Եթե ցանկանում եք ավելի մանրամասն մանրամասնել, թե ինչ է քննարկվում այստեղ, կարող եք ստուգել համապատասխան բովանդակությունը ավելի ուշ այս ուղեցույցում: Եթե դուք սեղմված եք ժամանակի համար, կարող եք նաև սեղմել այստեղ՝ այս ուղեցույցի մանրամասները ներբեռնելու համար Օդային ճնշման ցուցիչի արտադրանք PDF տվյալներ.

Այլ սենսորային տեխնոլոգիաների մասին լրացուցիչ տեղեկությունների համար խնդրում ենք Այցելեք մեր տվիչների էջը.