Katalog

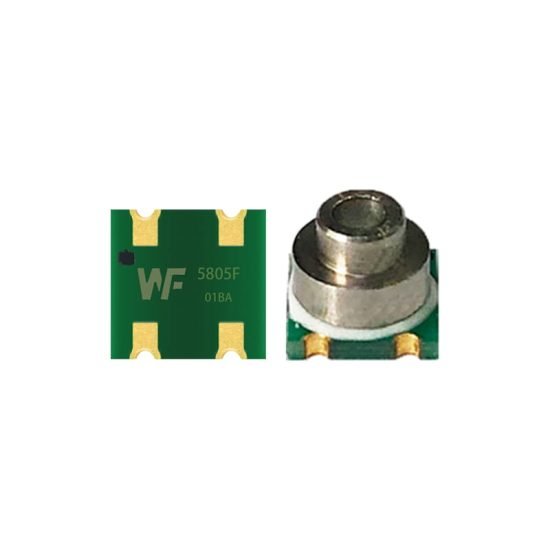

The WF5805-2BAR barometric sensor serves as a critical component for modern model aircraft hovering technology. Through precise atmospheric pressure measurement, it achieves altitude control with 20cm resolution using 24-bit ΔΣ ADC technology, providing stable and reliable altitude reference for aircraft systems.

1. WF5805-2BAR Core Technical Features

High-Precision Pressure Measurement

WF5805-2BAR utilizes silicon micromachining technology with integrated high-linearity pressure sensing elements and ultra-low power 24-bit ADC. The sensor converts mechanical pressure into electrical signals through piezoresistive effects, ensuring excellent linearity within 300-1200 mbar operating range.

Low Power & Fast Response Design

With standby current below 0.15μA and operating current of 0.6μA, the sensor optimizes battery life. 0.5ms conversion rate enables real-time altitude tracking, providing timely feedback for control systems. I2C interface simplifies connections without external components.

2. Aircraft Hovering Altitude Control

Barometric Altitude Calculation

The sensor measures atmospheric static pressure changes following standard atmospheric pressure laws. Every 9-meter altitude increase corresponds to 100Pa pressure decrease. WF5805-2BAR’s high resolution detects pressure differences equivalent to 20cm altitude changes.

Multi-Sensor Fusion Algorithm

Pure barometric measurement cannot meet hovering precision requirements. Z-axis accelerometer data undergoes double integration for vertical velocity and displacement calculation. Kalman filter optimally estimates barometric and inertial navigation data, improving control accuracy to ±50cm range.

Cascaded PID Control Strategy

Hovering control employs multi-loop cascaded PID structure controlling altitude error, vertical velocity, and vertical acceleration respectively. Throttle output regulates climb rate rather than direct motor speed, ensuring stable hovering without oscillation.

3. Airflow Interference & Compensation

Static Pressure Environment Effects

WF5805-2BAR measures atmospheric static pressure, theoretically unaffected by airflow velocity. However, propeller downwash and aerodynamic effects create local pressure disturbances. High-speed flight accelerates airflow around sensors, reducing local static pressure and causing altitude overestimation.

Sensor Installation & Zaštita

Sensor positioning should avoid direct propeller airflow zones, typically located at aircraft center or bottom in stable pressure areas. Foam wrapping maintains atmospheric pressure connection while attenuating high-frequency airflow pulsations, significantly improving flight altitude measurement accuracy.

4. Temperature Compensation & Kalibriranje

Temperature Drift Correction

WF5805-2BAR includes high-precision temperature sensors monitoring environmental changes. Temperature variations affect silicon diaphragm elastic modulus and resistance characteristics. Internal algorithms automatically perform temperature compensation across -40 to +85°C range.

Pre-flight Pressure Calibration

Each flight requires barometric zero-point calibration, setting current atmospheric pressure as altitude reference. Calibration involves continuous sampling for several seconds, averaging values to eliminate short-term pressure fluctuations.

5. Performance Optimization & Prijave

Flight Performance Analysis

Flight testing shows WF5805-2BAR maintains ±20cm altitude accuracy during static hovering. Horizontal speeds below 10m/s minimally affect altitude performance, though full-speed flight may cause 2m altitude deviation due to aerodynamic interference.

Cost-Effectiveness & Pouzdanost

WF5805-2BAR provides cost-effective precision compared to complex laser ranging or vision systems. Sealed design and excellent long-term stability ensure reliable operation in harsh environments, reducing maintenance costs for model aircraft enthusiasts.

Zaključak

The WF5805-2BAR air pressure sensor has become the core device of model aircraft hovering technology due to its high precision, low power consumption and fast response characteristics. Through multi-sensor fusion, intelligent algorithm optimization and systematic compensation measures, the sensor can provide stable and reliable altitude control capabilities in complex flight environments. Reasonable installation design and calibration procedures further improve system performance, enabling model aircraft to achieve precise automatic hovering functions. With the continuous development of MEMS technology, the application of air pressure sensors in the field of model aircraft will become more extensive and mature.

Gornji uvod samo zagrebe površinu primjene tehnologije senzora tlaka. Nastavit ćemo istraživati različite vrste senzorskih elemenata koji se koriste u različitim proizvodima, kako rade te njihove prednosti i nedostatke. Ako želite više pojedinosti o tome što se ovdje raspravlja, možete provjeriti povezani sadržaj kasnije u ovom vodiču. Ako ste u stisci s vremenom, također možete kliknuti ovdje za preuzimanje pojedinosti o ovim vodičima Podaci o senzoru zračnog tlaka PDF podaci.

Za više informacija o drugim tehnologijama senzora, molimo Posjetite našu stranicu senzora.