Katalog

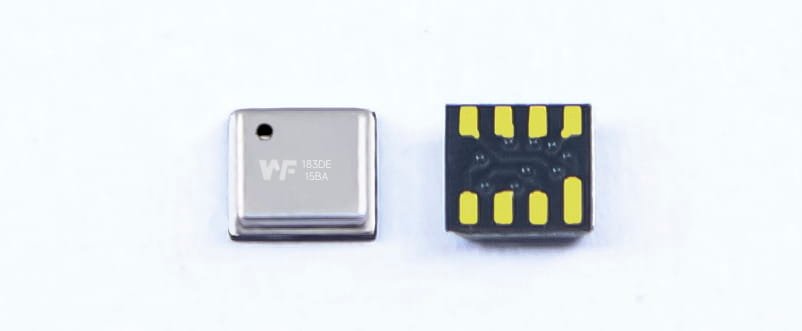

This article presents an end-to-end solution for integrating the WF183DE digital MEMS pressure sensor into an emergency starter power-bank air pump—featuring four inflation modes (basketball, bicycle, motorcycle, car), auto-stop intelligence, multi-unit switching, built-in lighting, and comprehensive safety protections. We cover requirements analysis, hardware selection, mounting and soldering best practices, pre-production testing workflows and tools, as well as firmware and system integration, providing engineers, purchasing managers, and technical decision-makers with a clear, reliable guide to ensure precision, stability, and superior user experience.

System Requirements & Sensor Role

1.1 Functional Overview

Safety Assurance: Monitors and replenishes tire pressure to prevent roadside hazards.

Multi-mode Support: Four presets (basketball, bicycle, motorcycle, car) cover pressures from ~8 PSI to 150 PSI.

Auto-Stop: Over-pressure and deflation thresholds trigger pump shutoff when target pressure is reached.

Unit Switching: PSI, BAR, KPA options for user preference.

Illumination: Integrated LED for low-light operation.

Full-Auto & Zaštita: Over-temp, over-current, low-voltage shutdown, and auto-activation via pressure trigger.

1.2 Sensor Capabilities

Točnost: ±1 %FS covers entire 0–150 PSI range.

Digital Interface: PDM or I²C/SPI output for robust MCU communication.

Low Power: µA-level consumption extends battery life.

Compact: 3 × 3 mm LGA footprint fits tight pump housings.

1.3 Solution Mapping

Map four modes to pressure setpoints (e.g., basketball (~8 PSI), bicycle (0–60 PSI), motorcycle (0–80 PSI), and car (0–150 PSI). The WF183DE’s 0–150 PSI range easily maps to these modes with firmware thresholds and auto-mode switching ).

Implement auto-stop via firmware interrupts on threshold reached.

Integrate unit conversion in MCU for real-time display.

Mounting & Soldering Guidelines

2.1 PCB Layout

Top-port Alignment: Ensure the sensor’s sampling port faces the pump’s air channel unobstructed.

Clearance: ≥0.5 mm around the port to prevent solder bridging.

Thermal Isolation: Avoid large copper pours beneath to minimize thermal drift.

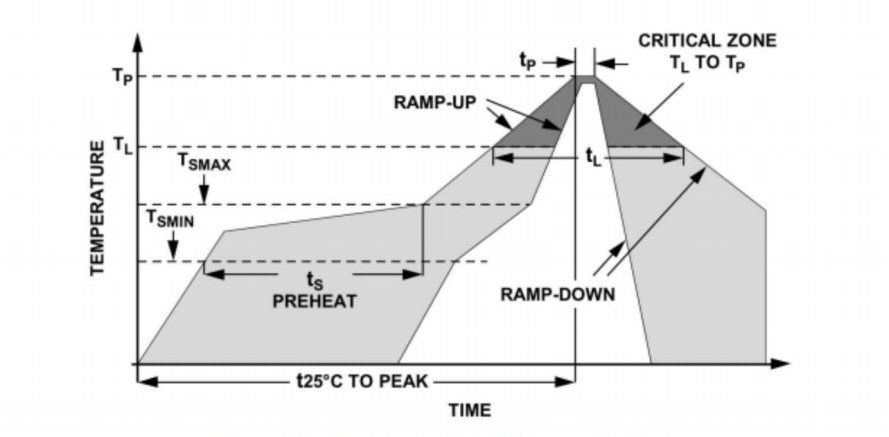

2.2 Reflow Profile

Peak ≤ 260 ℃, ramp ≤ 2 ℃/s, 30–60 s above liquidus per JEDEC J-STD-020.

Controlled solder paste volume via fine-mesh stencil.

Use appropriate flux to avoid port clogging.

2.3 Protective Measures

Apply silicone dot sealing around edges, leaving ports clear.

Black-coat inner walls to prevent light interference if co-locating with optics.

Pre-Production Testing & Alati

3.1 First Article Inspection

Pressure Calibrator (e.g., I2C Digital Pressure sensor test module): five-point linearity and accuracy checks.

Thermal Chamber: −20 ℃, 25 ℃, 85 ℃ cycles for drift evaluation.

Vibration/Shock: ISO 16750-3 for automotive-grade durability.

3.2 Production-Line QA

Flying Probe: pin-continuity and impedance check.

Leak Test: ≤ 1×10⁻⁶ mbar·L/s putem automatiziranih uređaja.

Funkcionalno učvršćenje: ugrađena pumpa i izvor zraka s MES-povezanim zapisnicima o prolazu/pauzi za zadanu vrijednost, prekidač jedinice, provjera valjanosti automatskog zaustavljanja.

3.2 valni filter

Kako bi se uravnotežio odziv i stabilnost, jednostavan IIR ili filtar pomičnog prosjeka primjenjuje se na podatke senzora za suzbijanje šuma bez ugrožavanja povratne informacije u stvarnom vremenu

Firmware & Integracija sustava

4.1 Osnove firmvera

Upravljan prekidom otkrivanje praga za brzo isključivanje pumpe.

Filtriranje: IIR ili pomični prosjek za ravnotežu odziva i stabilnosti.

Samotestiranje: Očitavanje ID-a senzora i zdravstvenih registara pri uključivanju.

4.2 Korisničko sučelje

Prikaz trenutnog u odnosu na ciljni tlak i postotak punjenja u stvarnom vremenu.

Gumb/okretni birač za promjenu načina rada i jedinice sa zvučnom povratnom informacijom.

Automatsko pozadinsko osvjetljenje pri detekciji slabog osvjetljenja.

Pouzdanost & Compliance

5.1 Burn-in & Aging

- 168 h at 85 %RH/85 ℃, monitor drift < ±2 %FS and motor performance.

5.2 Regulatory & Safety

EMC: IEC 61000-4-2/-4-3 ESD and radiated immunity.

Safety: UL 62368-1 for insulation and over-current protection in the power module.

Zaključak

By systematically addressing sensor selection, PCB design, soldering, validation testing, firmware, UI, and compliance, this guide delivers a turnkey solution for integrating the WF183DE digital pressure sensor into an emergency air-pump module—ensuring high precision, robust performance, and end-user safety.

Gornji uvod samo zagrebe površinu primjene tehnologije senzora tlaka. Nastavit ćemo istraživati različite vrste senzorskih elemenata koji se koriste u različitim proizvodima, kako rade te njihove prednosti i nedostatke. Ako želite više pojedinosti o tome što se ovdje raspravlja, možete provjeriti povezani sadržaj kasnije u ovom vodiču. Ako ste u stisci s vremenom, također možete kliknuti ovdje za preuzimanje pojedinosti o ovim vodičima Podaci o senzoru zračnog tlaka PDF podaci.

Za više informacija o drugim tehnologijama senzora, molimo Posjetite našu stranicu senzora.