Katalog

High-resolution MEMS pressure sensors, when integrated into pneumatic caulking equipment, provide real-time pressure monitoring and closed-loop control. That stability keeps dispense volume steady, cuts material waste, and raises equipment reliability. Based on collected images and technical notes, this article explains sensor basics, precise dispense control, protection and safety features, automation integration, and energy and maintenance gains

1. MEMS Pressure Sensor Basics and How They Work

Sensing mechanism and signal flow

MEMS piezoresistive sensors use a silicon diaphragm that flexes under pressure. That flex changes embedded resistor values in a Wheatstone bridge. The bridge output is amplified and conditioned, then delivered as analog or digital output. Typical response is 1–5 ms and resolution can reach 0.05% FS. Interfaces commonly include I²C, SPI, and 4–20 mA, which plug directly into PLCs or MCUs for closed-loop control.

Packaging and electrical traits

Modern packages are compact, often ceramic or metal, with pins for power, ground, signal, and calibration. Many include a temperature sensor for onboard compensation. Typical supply voltages are 3.3 V or 5 V and power draw is low—suitable for handheld or line equipment. Mount sensors near the regulator or nozzle to reduce dead volume and speed response.

2. Precise Control of Sealant Output

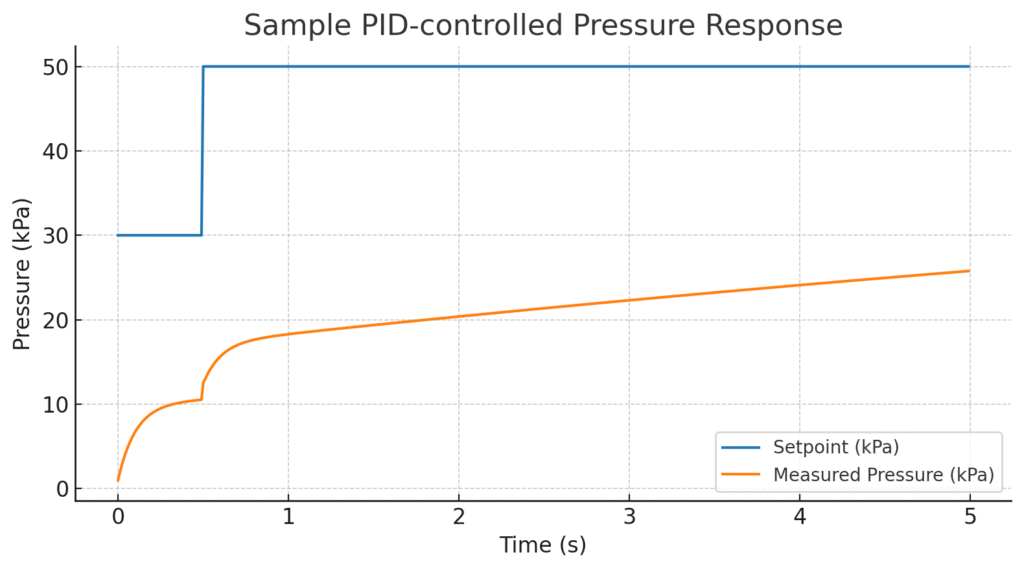

Real-time pressure feedback and closed-loop control

Pressure sensors stream pressure curves to the controller. The controller adjusts pump power or valve position to hold setpoint pressure, keeping extrusion steady. This closed-loop removes effects of source fluctuations, line resistance, and temperature shifts. Target control accuracy of ±0.5% FS is realistic with a properly tuned loop, improving bead width and flow repeatability.

Material-adaptive pressure tuning

Different sealants need different drive pressures. The control system uses pressure rise, steady-state pressure, and optionally temperature to select the correct control profile. High-viscosity materials run at higher steady pressure; low-viscosity materials need lower pressure to avoid over-dispense. Automating profile call-up reduces manual setup and speeds changeovers.

Temperature compensation and environmental handling

Temperature affects sealant rheology and air properties. Built-in temperature compensation or a simple pressure–temperature matrix helps correct measurement drift and maintain consistent flow. Proper compensation keeps performance stable across a wide working range (roughly −20°C to +60°C in typical designs).

3. Equipment Protection and Safety Monitoring

Overpressure protection and emergency shutdown

Sensors trigger protection when pressure exceeds safe limits—common causes include nozzle clog, kinked hose, or cured material blocking flow. Set safety thresholds and a fast response path to stop pumps or close valves. Response times under 10 ms and clear fault logging protect equipment and operators from spray or mechanical failure.

Low-pressure alerts and supply checks

Low pressure indicates source issues or leaks and can ruin a run. Low-pressure alarms notify operators before quality suffers. Set low-pressure thresholds to avoid false alarms while still catching real faults. Monitoring pressure rise time gives a quick view of system sealing health.

4. Automation and Intelligent Integration

PLC integration and line-level control

MEMS sensors talk to PLCs over standard buses, providing live pressure and status. PLCs load product-specific pressure programs so the line can switch products with minimal delay. Multi-station coordination keeps bead quality consistent across work stations and simplifies production flow.

Data capture and process tuning

Store pressure trends, alarms, and event markers for offline analysis. Trend data helps spot nozzle wear, pump degradation, or material change. Use logged data to tune control parameters or build simple predictive models for maintenance planning. Aggregated data improves repeatability and reduces downtime.

5. Energy Efficiency and Equipment Life

On-demand pressure and energy savings

Instead of constant high-pressure supply, use demand-driven control: lower pressure in standby, ramp up only when dispensing. For intermittent work this can cut compressor runtime and energy use substantially—typical savings in the 20–30% range in many setups.

Wear reduction and maintenance scheduling

Stable pressure reduces shock loading on seals, valves, and fittings. Track pressure fluctuation patterns to identify components that are degrading. Condition-based maintenance guided by sensor data is more efficient than fixed-interval servicing and can extend component life by double-digit percentages.

Zaključak

Using high-performance MEMS pressure sensors as the feedback core of pneumatic caulking equipment converts manual guesswork into repeatable, controllable process parameters. Real-time monitoring, closed-loop control, safety cutoffs, material-adaptive profiles, and data-driven maintenance together raise dispense consistency, safety, and energy efficiency. With correct mounting, sampling, filtering, alarm thresholds, and PID tuning, teams can deploy stable, production-grade caulking systems that scale from single tools to automated lines.

Gornji uvod samo zagrebe površinu primjene tehnologije senzora tlaka. Nastavit ćemo istraživati različite vrste senzorskih elemenata koji se koriste u različitim proizvodima, kako rade te njihove prednosti i nedostatke. Ako želite više pojedinosti o tome što se ovdje raspravlja, možete provjeriti povezani sadržaj kasnije u ovom vodiču. Ako ste u stisci s vremenom, također možete kliknuti ovdje za preuzimanje pojedinosti o ovim vodičima Podaci o senzoru zračnog tlaka PDF podaci.

Za više informacija o drugim tehnologijama senzora, molimo Posjetite našu stranicu senzora.