Katalog

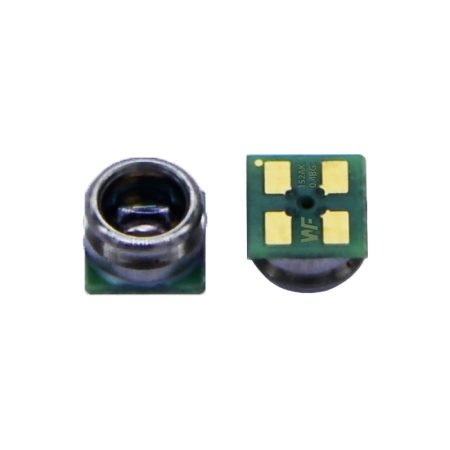

Liquid-level measurement depends on accurate pressure signals for closed-loop control and safety. The pictured waterproof MEMS pressure sensor integrates a piezoresistive silicon die, dedicated signal conditioning, and a 24-bit Σ-Δ ADC to deliver temperature- and linear-compensated digital pressure output. It converts water height into stable, high-resolution electrical data for appliances, small-scale water treatment and municipal or industrial water systems, enabling reliable automation and timely alarms.

1. Principle and Device Structure

Hydrostatic pressure sensing, piezoresistive detection, and digital output

Liquid level is measured by hydrostatic pressure: the column of water applies force to the sensor face, deforming a piezoresistive silicon diaphragm. Embedded resistors change value with that deformation, forming a bridge that the signal-conditioning stage amplifies and converts to digital form. Built-in temperature and linear compensation and a 24-bit Σ-Δ ADC yield high-resolution, low-noise pressure readings that plug directly into controllers or bus interfaces.

Manufacturing uses single-port or waterproof cavity packaging; designers may choose isolation media or diaphragms to handle corrosive, viscous, or particle-laden liquids. Digital output reduces the need for external conditioning and simplifies system integration.

2. Accuracy and Long-term Stability

Digital compensation and high-resolution ADC for stable measurements

Accurate level control requires stable zero and low drift. Integrated temperature compensation and linearity correction reduce thermal drift and nonlinearity; the 24-bit Σ-Δ ADC enables detection of minute level changes while maintaining repeatability over time. The sensor’s low-power signal conditioning and onboard filtering suppress noise, improving resolution for both small-range domestic applications and large-range industrial tanks.

These features keep measurements traceable and reliable even under temperature swings and flow disturbances.

3. Installation, Compatibility, and Application Fit

Compact packaging and material choices ensure deployability across scenarios

Practical deployment must consider fluid chemistry, mounting position, and interface standards. Compact SMD or threaded housings ease sidewall or bottom mounting; material selection (stainless steel, ceramic, or corrosion-resistant alloys) and diaphragm choice should match the fluid’s corrosivity, viscosity, and particulate content to extend life and cut maintenance.

Sensors can be factory-configured with output options (I²C, SPI, 4–20 mA, etc.) to match controllers. Evaluating liquid temperature and pressure range up front greatly increases first-time installation success.

4. Immunity to Disturbance and Robustness

Packaging, isolation and digital filtering improve field immunity

Field level measurement faces foam, bubbles, electromagnetic noise and mechanical shocks. Single-port designs and isolation diaphragms reduce direct contamination risk; digital signal conditioning delivers filtering and fault detection that can flag abnormal waveforms and trigger alarms. Enclosures and connectors should meet required IP and chemical-resistance ratings to ensure long-term reliability.

Sensors that provide diagnostic codes or status outputs simplify remote monitoring and fault location, cutting downtime.

5. System Value: Closed-loop Control, Energy Savings, and Maintenance Gains

Real-time data drives closed-loop control and optimized operations

Real-time level data feed controllers to operate valves, pumps and heaters automatically, maintaining setpoints and triggering low- or high-level alarms. Precise control and demand-based management reduce energy use and material waste. Pressure waveform analysis can reveal seal, valve, or piping wear, enabling condition-based maintenance rather than time-based servicing.

Collected data support process tuning, remote diagnostics and life-cycle predictions, lowering total cost of ownership and improving uptime.

Zaključak

High-quality liquid-level measurement depends on sensor design: a piezoresistive silicon die, digital temperature and linear compensation, a 24-bit Σ-Δ ADC, and compatible, robust packaging and materials. With the right installation and interfaces, waterproof MEMS pressure sensors provide stable, high-resolution level data in complex water environments, enabling reliable automation, prompt alarms, energy savings, and smarter maintenance decisions.

Gornji uvod samo zagrebe površinu primjene tehnologije senzora tlaka. Nastavit ćemo istraživati različite vrste senzorskih elemenata koji se koriste u različitim proizvodima, kako rade te njihove prednosti i nedostatke. Ako želite više pojedinosti o tome što se ovdje raspravlja, možete provjeriti povezani sadržaj kasnije u ovom vodiču. Ako ste u stisci s vremenom, također možete kliknuti ovdje za preuzimanje pojedinosti o ovim vodičima Podaci o senzoru zračnog tlaka PDF podaci.

Za više informacija o drugim tehnologijama senzora, molimo Posjetite našu stranicu senzora.