Nowadays, under the continuous growth of modern technology, the application of gas pressure sensors in many industries is gradually emphasized. Gas sensing technology, especially the development of gas pressure sensors, is becoming one of the key technologies indispensable to environmental monitoring, industrial automation, medical and health fields. Gas pressure sensors through accurate measurement of gas pressure changes, not only improve the accuracy of gas detection, but also promote the innovation and upgrading of related technologies. The emergence of gas pressure sensors, so that the gas concentration, gas flow and gas state monitoring has become more efficient and accurate, thus bringing far-reaching changes to many traditional industries.

The innovative role of gas pressure sensors in gas sensing technology is mainly reflected in their improved detection accuracy, response speed, stability and durability. These innovations have led to a wider application of gas sensing technology in industrial control, environmental protection, medical diagnosis, and automobile safety. In this paper, we will explore the innovative role played by gas pressure sensors in gas sensing technology, analyze its working principle, technical advantages and application areas, with the aim of comprehensively explaining how this key technology can promote technological innovation in the industry.

Počnimo čitati!

Sadržaj

1. The basic principle of the gas pressure sensor and the way of work

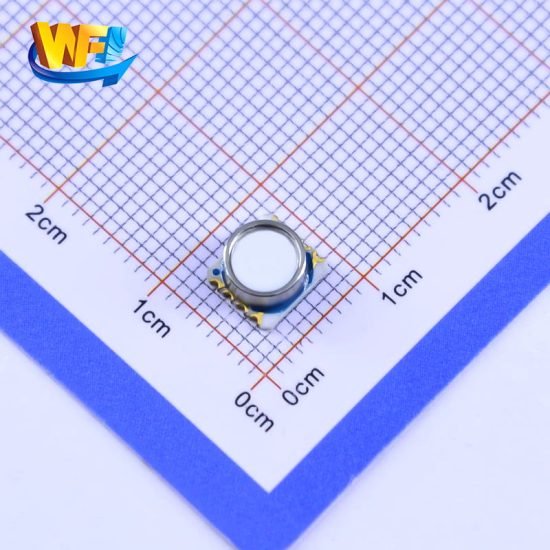

Gas pressure sensor as a sensor used to detect changes in gas pressure, has a unique working principle. The core part is usually a pressure-sensitive element, can be deformed under the action of external gas pressure, and this deformation is converted into a telecommunication signal output. According to different sensing principles, gas pressure sensors can be divided into a variety of types, including capacitive, piezoresistive, fiber-optic, strain relief and so on.

Among them, piezoresistive gas pressure sensor is the most widely used one. It uses the piezoresistive effect, that is, the material’s resistance value with the external pressure changes and changes in the characteristics of the precise measurement of the change in resistance value to determine the pressure of the gas. Capacitive sensor is through the detection of pressure-induced changes in capacitance to achieve the measurement of gas pressure. Fiber-optic sensor through the use of optical fiber optical properties to sense pressure changes, with high precision and sensitivity.

The operating principle and technical details of these sensors determine the applicability and performance of gas pressure sensors in different scenarios. They can convert small gas pressure changes into electrical signals, which can be further converted into analyzable and monitorable data by connecting to signal processing equipment.

2.The innovative role of gas pressure sensor on gas sensing technology

1. Improve gas detection accuracy and sensitivity

One of the biggest innovations of the gas pressure sensor is its high sensitivity to gas pressure. In traditional gas detection equipment, the measurement of gas concentration is often limited by the precision and sensitivity of the sensor, while the application of gas pressure sensors can significantly improve the precision and stability of this measurement. Changes in gas pressure can directly reflect changes in gas concentration, especially in environments with higher or lower gas densities, gas pressure sensors are able to capture small changes with higher sensitivity and provide more accurate data support.

Example, in air quality monitoring, gas pressure sensors can indirectly determine the concentration of a certain pollutant by sensing the pressure change of the gas in the air. When the pressure of the gas and the concentration of a certain linear relationship, through the precise measurement of gas pressure changes, you can accurately determine the specific concentration of pollutants in the air. This type of detection based on pressure change is usually more accurate than the traditional detection based on chemical reaction of the gas.

2. Improved Response Time and Real-Time Monitoring Capability

Another innovative advantage of gas pressure sensors is their faster response time. Traditional gas detection methods, such as chemical sensors, may require a certain response time to produce stable results. Gas pressure sensors, on the other hand, can respond quickly to changes in gas pressure at the microsecond level, greatly improving real-time monitoring capabilities.

This feature is particularly important in industrial automation and smart manufacturing. For example, in gas leak detection systems, gas pressure sensors are able to quickly detect pressure changes caused by gas leaks and provide timely alerts. This quick response not only improves safety, but also increases productivity. In the medical field, gas pressure sensors are used in respirators and other equipment to monitor the patient’s airway pressure changes in real time to ensure the normal operation of the respiratory system.

3. Enhanced stability and reliability

The stability and reliability of gas pressure sensors in long-term use is another important advantage of their innovation. Conventional gas sensors can be affected by factors such as temperature, humidity and gas composition, resulting in errors during long-term operation. Gas pressure sensors, on the other hand, have improved their stability under different environmental conditions through multiple technical means, such as temperature compensation and anti-interference design.

For example, in harsh industrial environments, gas pressure sensors are able to operate stably under conditions of high temperature, high humidity, and strong electromagnetic interference. This stability makes the gas pressure sensor in a long time, high intensity use can still maintain high measurement accuracy, widely used in petroleum, chemical, metallurgical and other industries of gas detection.

4. Expanding application areas and innovative solutions

The innovativeness of gas pressure sensors is also reflected in its expanding application areas. From the early simple gas detection to today’s multi-disciplinary applications, gas pressure sensors not only play an important role in environmental monitoring, in the automotive, medical, aviation and aerospace fields have also achieved significant results.

In the automotive industry, gas pressure sensors are used in on-board gas detection systems, capable of detecting changes in fuel vapor, interior air quality, and the pressure of the on-board gas system, thereby protecting the safety of the driver and the freshness of the air inside the vehicle. Especially in the field of electric vehicles, gas pressure sensors are used for battery gas leakage detection to prevent battery explosion and other safety hazards.

In the medical field, gas pressure sensors are widely used in respirators, gas anesthesia equipment, gas delivery lines and other equipment to monitor changes in gas pressure to ensure the safety of patients. In the life support system, the accurate measurement of gas pressure is crucial to the patient’s respiration and blood oxygen concentration monitoring, the innovation of gas pressure sensors makes these equipments more reliable.

3. Challenges and Prospects of Gas Pressure Sensors in Gas Sensing Technology

Although gas pressure sensors play an important role in gas sensing technology, they still face some challenges. First, the adaptability of gas pressure sensors in extreme environments still needs to be further improved. In some high-temperature, high-pressure, and highly corrosive environments, the stability and durability of the sensors may be affected, and it is still necessary to solve these problems through innovations in material technology and structural design.

Secondly, the cost of gas pressure sensors is still one of the factors limiting their wide application. High-precision, high-stability gas pressure sensors are usually more expensive, which makes some small and medium-sized enterprises or emerging industries in the initial application of cost pressure. Therefore, how to reduce costs and improve production efficiency is also an important direction for the future development of gas pressure sensor technology.

However, with the continuous progress of materials science, nanotechnology and integrated circuit technology, the performance of gas pressure sensors is expected to further enhance. Future gas pressure sensors will be more miniaturized, low-power, highly integrated, and able to meet the needs of a wider range of fields. In addition, the application of artificial intelligence and big data technology will enable the gas pressure sensor can be combined with the Internet of Things system and cloud platform to achieve more intelligent gas detection and monitoring.

Zaključak

In short, gas pressure sensors as a key component of gas sensing technology, not only enhance the accuracy and sensitivity of gas detection, but also promote the innovative application of gas sensing technology in various industries. Its high response rate, stability and reliability make it an important technical support for environmental monitoring, industrial safety, medical diagnosis and other fields.