- Po WFsenzori

Force sensors boosting user experience and the smart capabilities of electronic instruments is about marrying hardware with playing logic. From an engineering viewpoint, this piece focuses on sensor selection, signal-chain design, modular outputs and rental/maintenance scenarios — showing how a high-performance analogue pressure module turns tiny force changes into stable, usable control signals.

Katalog

1. The core role of force sensors in electronic instruments

Force sensors are more than data sources — they turn a player’s action into musical expression. For performers, sensor sensitivity, bandwidth and linearity directly affect loudness, tone and nuance. Engineering starts with device selection: match the range, ensure zero-point stability and control temperature drift to avoid visible nonlinearity or step noise during play. Take tension sensors or analogue pressure sensors: when measuring string tension or breath pressure, the sensor must respond and be sampled in step with audio or control frame rates to avoid a laggy feel. Mechanical coupling matters too — mounting, elastic connections and damping change the effective passband, so engineers should run frequency response tests in prototype stages to settle on the best mounting and firmware filtering. User experience isn’t just single-session accuracy; it includes long-term stability and easy maintenance — which determine whether a product can succeed commercially or in rental fleets.

Sensor–human interaction

In human interaction, sensors must detect continuous action from gentle touches to hard hits. For example, in electronic wind instruments, sensors need to translate continuous breath intensity into volume or filter changes without producing a “stepped” or quantised feel. Achieving that requires low-noise amplification and adjustable response curves in firmware, plus user presets so people of different sizes or breathing patterns (kids vs adults) can quickly find a comfortable feel. Natural human–machine interaction is the key metric of success.

2. Signal amplification and micro-pressure transducer digital module integration

At the module level, a solid signal chain is crucial. A common approach uses a diffused-silicon pressure chip arranged as a Wheatstone bridge, followed by a dedicated IC that amplifies, filters and digitises the bridge output. A modular micro-pressure transducer digital module that bundles sensing, temperature compensation and linearisation can cut development time and reduce tuning risk. For engineering teams, the advantages are clear: temperature compensation and calibration are already done, outputs drive downstream controllers directly (for example 0.5–4.5 V or digital interfaces), and batch consistency is much better — which matters for production and upkeep.

Acquisition chain design

Designing the acquisition chain is about trade-offs between noise, bandwidth and power. A low source-impedance bridge with amplifiers that have high common-mode rejection lowers susceptibility to interference; filters and anti-aliasing should match the final control rate to avoid needless data. The system sampling rate must cover the shortest playing dynamics (fast tonguing or string plucks), while smart wake strategies cut power usage. These engineering choices directly affect audio quality and battery life.

3. Technical paths to upgrade rental and commercial services

In rental or large deployments, raw sensor performance alone won’t cover commercial needs — device health and operational data are equally important. Embedding basic status monitoring (average pressure peaks, response latency, abnormal patterns) enables remote diagnostics, usage-based billing and targeted maintenance. Technically, modules should support low-power modes but retain basic timing/counting, and be able to report or trigger protection when anomalies appear.

Maintenance automation

Remote diagnostics can analyse sampling data to spot wear or contamination and prompt cleaning or replacement. Usage-based billing — charging by effective playing time detected via pressure thresholds — turns sensor data into revenue streams. Implementing these features needs a reliable data channel between module and cloud, while respecting user privacy and security. Operators can then use the data to optimise stock and services, lowering total cost of ownership.

4. Smart interaction

Force sensors add value beyond real-time control — they enable data-driven, personalised experiences. Systems can auto-tune response curves based on play data, offering “Beginner”, “Intermediate” and “Pro” modes so different skill levels get an appropriate feel. Teaching aids can analyse curves to flag breath stability or pluck consistency and give simple feedback to help users improve.

User profiling and flexible response strategies

Building user profiles means combining short- and long-term data to tweak device parameters or suggest practice routines. For engineers, this implies a split responsibility between local firmware and cloud analytics: local code must guarantee low-latency control, while cloud algorithms handle long-term optimisation and push updates. This layered approach keeps immediate response snappy and allows continuous service improvement.

5. Reliability, production and engineering integration considerations

Bringing a design to market demands tight control over materials, packaging and calibration. Sensor modules should use durable, easy-clean materials (for instance, aluminium alloy base plates and medical-grade surface coatings) so the mouthpiece area can be disinfected without harming accuracy. Modules should ship with temperature compensation and calibration complete, and with a stable voltage output range (e.g. 0.5–4.5 V) so downstream systems can read data directly, reducing integration complexity. Good after-sales support and technical guidance cut customer integration hurdles and raise adoption rates.

Structural durability, cleaning compatibility and low-power wake strategies

In rental fleets, mouthpieces and contact areas get cleaned often. Hardware must tolerate alcohol wipes or allow quick replacement of surface parts, while internal design resists moisture from saliva. Low-power wake strategies (threshold-based event detection) keep devices in deep standby for long periods, and switch to high-sample modes instantly when activity occurs — balancing battery life with play responsiveness.

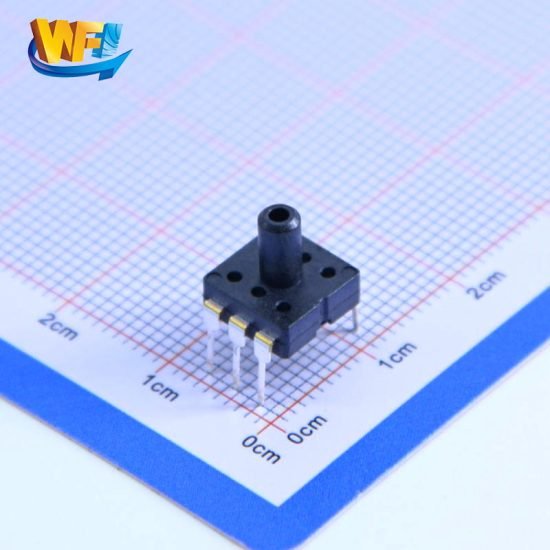

Product description and engineering advantages (modular note)

The micro-pressure measurement module used here employs a diffused-silicon pressure chip as the sensing core; the chip forms a Wheatstone bridge mechanically, and a dedicated IC amplifies, processes and outputs the signal. Temperature measurement uses a thermistor; the module already implements temperature compensation and factory calibration, and outputs a 0.5–4.5 V voltage signal for easy connection to common controllers. To boost reliability, the module uses an aluminium alloy base and is packaged for straightforward assembly. The manufacturer provides full technical support and after-sales help, so customers can integrate the module into prototypes and production faster, shortening development cycles and cutting risk.

Zaključak

Integrating high-performance force sensors into electronic instruments is a direct way to make playing feel more natural and to add smart features. From an engineering perspective, you need to design for device choice, signal chain, temperature/humidity compensation, low-power strategies and modular integration together — only then will you get both instantaneous playing response and the data needed for rental and operational smart services. Choosing pre-compensated, factory-calibrated micro-pressure transducer modules can greatly lower integration cost and risk, freeing hardware teams to focus on user experience and algorithm work.

Gornji uvod samo zagrebe površinu primjene tehnologije senzora tlaka. Nastavit ćemo istraživati različite vrste senzorskih elemenata koji se koriste u različitim proizvodima, kako rade te njihove prednosti i nedostatke. Ako želite više pojedinosti o tome što se ovdje raspravlja, možete provjeriti povezani sadržaj kasnije u ovom vodiču. Ako ste u stisci s vremenom, također možete kliknuti ovdje za preuzimanje pojedinosti o ovim vodičima Podaci o senzoru zračnog tlaka PDF podaci.

Za više informacija o drugim tehnologijama senzora, molimo Posjetite našu stranicu senzora.