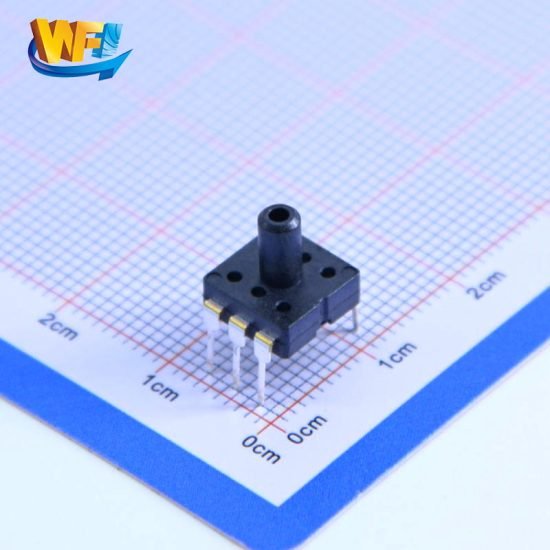

Modern washers use pressure sensors for water-level sensing, inlet control and overflow logic. Picking the right sensor — positive, negative or bidirectional (positive/negative) — and pairing it with temperature-compensated, factory-calibrated, or amplified calibrated sensors helps the machine meet programme needs, cut energy use and boost reliability. Based on the small mV analogue sensor pictured, this guide gives practical engineering advice for product development and supply-chain choices.

सूची

1. Role of pressure sensors in washing machines

the real-time “water level keeper

Pressure sensors convert the drum’s water level into an electrical signal the controller can act on. For engineers, choosing a stable mV analogue sensor or an amplified, calibrated unit cuts backend analogue design work. Using negative or bidirectional sensors can boost sensitivity in special inlet layouts. The right choice ensures the machine fills “to match the load”, improves wash results and conserves water and energy — all of which raise product appeal and customer satisfaction.

2. Key specs and sensor types

balancing resolution, linearity, drift and output

Decision makers should focus on resolution, linearity, sensitivity, thermal drift and output format (mV analogue or differential). Factory-calibrated and factory-compensation sensors leave zero and span adjusted at the factory, saving on system-level calibration. Temperature-compensated sensors reduce environmental effects so cycle decisions stay steady. Positive pressure sensors suit direct water-pressure measurement; negative pressure sensors work well with air-chamber isolation; positive/negative sensors are ideal for differential measurements.

3. System integration and signal handling

sensor to controller — amplification, filtering and fault detection

When the sensor output is at microvolt or mV level, use a low-noise amplifier and simple analogue filtering before the ADC and MCU do digital correction. Amplified, calibrated sensors can eliminate much of the analogue amplifier requirement and reduce introduced noise. The system should detect anomalies (sudden jumps or persistent drift) and trigger overflow stop or alarms. Good EMC practice and grounding reduce false triggers and keep the washer stable over the long term.

4. Calibration and temperature compensation approaches

factory calibration vs in-field temperature correction

Factory-compensated sensors handle zero, sensitivity and temperature drift on the production line, cutting end-product setup time. Still, field conditions (temperature swings, mechanical stress) benefit from software compensation. Combining factory-calibrated sensors with a software temperature compensation routine maintains accuracy across a wide range (for example −20°C to +60°C). Keep a calibration register or coefficient interface in the device so firmware updates and batch tracking are straightforward.

5. Reliability and maintenance advice

design choices for longevity, contamination resistance and fail-safe behaviour

Longevity depends on materials, sealing and factory calibration processes. Choose sensor packages that resist moisture and detergent deposits, and use air isolation or simple filters in the pressure path to reduce fouling. At the control level, include redundancy checks and quick self-tests on power-up (for example, a rapid water-level read) plus temperature-compensation sensors and impact-resistant packaging. These measures keep the sensor stable in hot, humid conditions and cut after-sales costs.

निष्कर्ष

Pressure sensors are central to a washer’s water control and efficiency. Engineers and procurement leads should favour factory-calibrated, temperature-compensated mV analogue or amplified calibrated sensors to shorten development time, simplify system design and deliver a more reliable, energy-efficient product. The small mV analogue sensor pictured — with a hose nipple and three or four pins — is cost-effective for water-level detection and well suited to embedded controllers and mass production.

उपरोक्त परिचय केवल दबाव सेंसर प्रौद्योगिकी के अनुप्रयोगों की सतह को खरोंचता है। हम विभिन्न उत्पादों में उपयोग किए जाने वाले विभिन्न प्रकार के सेंसर तत्वों, वे कैसे काम करते हैं, और उनके फायदे और नुकसान का पता लगाना जारी रखेंगे। यदि आप यहां चर्चा की गई बातों पर अधिक विवरण चाहते हैं, तो आप बाद में इस गाइड में संबंधित सामग्री देख सकते हैं। यदि आप पर समय की कमी है, तो आप इस गाइड का विवरण डाउनलोड करने के लिए यहां क्लिक भी कर सकते हैं वायु दाब सेंसर उत्पाद पीडीएफ डेटा.

कृपया अन्य सेंसर प्रौद्योगिकियों पर अधिक जानकारी के लिए हमारे सेंसर पेज पर जाएँ.