Pressure sensors are a core component that lets smart window cleaners maintain stable suction, extend battery life and deliver safety protection. With high-precision absolute-pressure sensing, fast digital pressure sampling and anti-interference design, the machine can adapt suction to different glass types and wind conditions, improving cleaning efficiency while reducing the risk of falls.

Papa lima

1. Vacuum stability control

The number one job of a smart window cleaner is to keep suction reliable. By integrating an absolute-pressure sensor directly into the vacuum chamber feedback loop, the controller can read chamber pressure in real time and adjust the vacuum pump output as needed. That closed-loop control keeps suction within a safe band across different glass flatness and surface treatments (smooth glass, frosted glass or films). Reasonable thresholds — for example a working band from -60 kPa to -80 kPa and a low-pressure alarm at -40 kPa — prevent falls caused by insufficient suction and avoid over-suction that could stress or crack the glass. Using piezoresistive MEMS absolute sensors together with fast A/D conversion meets the <10 ms response requirement so the system can compensate for pressure swings when moving laterally or when gusts hit. In design, you must consider sensor placement, sealing and airway impedance — poor choices here cause measurement delays or cumulative errors.

Sensor circuits and absolute-pressure feedback strategy

Placing the absolute-pressure sensor close to the vacuum cavity shortens measurement latency and lets the controller change pump speed or switch auxiliary modules more promptly. On the hardware side, differential filtering and digital calibration reduce mechanical noise and temperature drift. On the software side, short sliding-window rate detection helps distinguish transient disturbances from actual leaks and triggers safety responses. High-end models often use dual-sensor redundancy: if the primary sensor fails, the backup takes over immediately so suction control stays uninterrupted.

2. Power management and runtime

Battery-powered models are very sensitive to runtime. Pressure sensors provide the exact inputs the power strategy needs so the vacuum pump only works as hard as necessary, avoiding needless high-power operation. By collecting a profile of suction needs — different surfaces and cleaning stages demand different pressure levels — control algorithms can set a minimum sustain power and move into low-power cruise or standby after stabilisation. Sensors also enable a “sleep-wake” flow: when stable pressure and no motion are detected, the system enters deep power saving; if pressure drifts or a remote command comes in, it wakes quickly. This demand-driven approach extends single-session runtime and lowers thermal load that would otherwise age seals faster.

Dynamic pump control and sleep strategies

Dynamic pump control maps sensor readings to pump drive current for fine adjustment; PID or adaptive control keeps suction stable while optimising power use. Sleep strategies require the sensor to keep sampling at low power or wake periodically so the system can respond early to small leaks. Good hardware design reduces gas-path leakage and tunes the pump’s minimum stable output — both directly affect efficiency curves and runtime.

3. Safety and fault detection

Safety is the lifeline of high-altitude cleaning. Pressure sensors don’t just handle normal control — they also provide fault warnings. By monitoring absolute pressure and its change rate, the system can tell a transient disturbance from real seal failure. For instance, if pressure keeps dropping faster than a set rate (say more than 5 kPa/s), the system can infer a damaged seal or a cracked pane, then sound an alarm, stop movement and activate a backup suction device. Graded alarm levels let the machine react differently depending on risk — from voice prompts to forced emergency braking — protecting people and property. Redundancy and built-in self-tests prevent single points of failure.

Leak-rate discrimination and redundancy takeover

Rate detection uses short-term differencing and threshold matching, combined with a historical baseline to cut down false alarms. Redundancy lets the controller switch to the spare sensor if the main one misbehaves, maintaining suction and giving users time to react safely. The system should log fault events for later maintenance and lifetime analysis.

4. Path coordination and edge recognition

Sensor data isn’t only for suction control — it works with motion control to optimise cleaning paths. Real-time pressure readings reflect changes in contact area and adhesion status; when approaching an edge or a contoured surface, pressure fluctuations tell the controller to slow or alter the trajectory to avoid overrun or excessive local pressure. Combining pressure with brush-motor current data helps estimate dirt resistance: if stubborn grime raises friction, the controller can increase brush force or repeat a pass. That multi-source data fusion makes the cleaner more robust on complex surfaces, improves cleaning rates and reduces the chance of glass damage.

Pressure sensing and path-adjustment algorithms

By building a pressure-to-contact-area model, the controller maps instantaneous pressure into a real contact state and adjusts speed and torque accordingly. Short-time filtering plus event-trigger logic keeps sensitivity while suppressing spurious signals. For large curtain-wall jobs, sharing pressure data among multiple units can prevent repetitive coverage and raise overall work efficiency.

5. Environmental compensation and protective design

Environmental changes affect pressure measurement and seal performance. Pairing temperature and humidity sensing with pressure measurement lets the system correct readings for thermal expansion or air-density shifts. For outdoor use, rugged protection to IP67 standard helps the sensor survive rain, dust and cleaning-solution spray. Don’t forget electromagnetic and mechanical vibration immunity — shielding and regulated power supplies stop noise corrupting digital pressure readings. Chemical-resistant seals and robust mechanical mounting lengthen system life and reduce maintenance frequency.

Temperature/humidity correction and waterproof/dustproof schemes

In calibration, the sensor’s temperature coefficient and humidity influence are stored in the controller so readings are corrected in real time. Physically, high-IP enclosures and drainage design ensure reliable long-term outdoor operation. The sensor module should use materials that resist cleaning agents and be easy to replace.

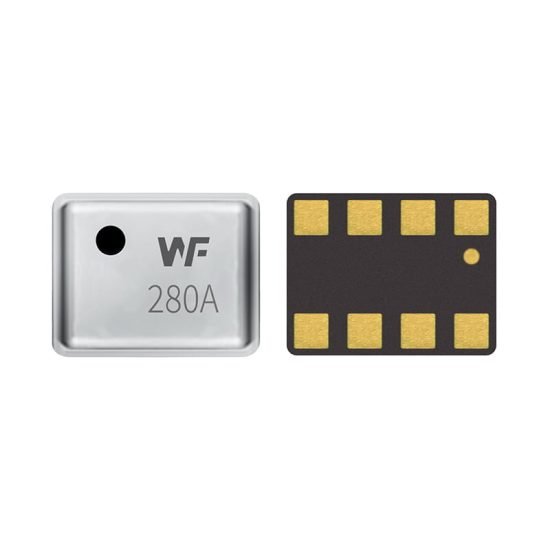

Hopena

Pressure sensors are both the safety anchor and the efficiency engine of smart window cleaners. Through precise absolute-pressure measurement, fast digital response, redundancy and fault discrimination, tight cooperation with motion control, plus environmental compensation and rugged protection, the whole machine can operate reliably under risky conditions while improving cleaning precision and runtime. From an engineering standpoint, pick sensors that cover -100 kPa to atmospheric pressure, with ±0.5%FS accuracy and <10 ms response (like the metal-cased absolute device shown in the image). Match sensor placement, hardware redundancy and calibration strategy carefully — these choices directly raise system reliability and user experience.

ʻO ka mea i hōʻikeʻia ma luna nei e hōʻike wale ana i kaʻili o nā noi o kaʻenehanaʻo Sensor Sensor. E hoʻomau mau mākou i nāʻano likeʻole o nāʻano sensor i hoʻohanaʻia ma nā huahana likeʻole, pehea lākou e hana ai, a me kā lākou hanaʻana. Inā makemakeʻoe eʻoi aku ka nui o nā kiko'ī ma ka mea i kamaʻilioʻia ma aneʻi, hiki iāʻoe ke nānā i nāʻike pili ma hope o kēia alakaʻi. Ināʻoe e kaomi no ka manawa, hiki iāʻoe ke kaomi ma aneʻi e hoʻoiho i nā kiko'ī o kēia mau alakaʻi ʻO kaʻikepili o ka ea eʻike ai i kaʻikepili PDF. ^.

No nāʻike hou aku ma nāʻenehana loea'ē aʻe, eʻoluʻolu E kipa i kā mākouʻaoʻaoʻike. ^.