- Na WFsensors

In blood pressure monitor design, the sensing element determines measurement quality and user safety. Using a pressure sensor specifically tuned for blood-pressure measurement lets you bundle signal acquisition, conditioning and calibration into one device — simplifying the system and improving consistency of readings. Digital MEMS pressure sensors advantages in blood pressure monitors across five dimensions: accuracy, range, redundancy for safety, power/packaging and thermal stability.

Papa lima

1. Accuracy and system design simplification

Why high-resolution internal outputs cut the burden on external conditioning circuits

Integrated sensing elements and signal-conditioning ASICs with a high-resolution ADC that deliver calibrated, temperature-compensated digital values mean you don’t need complex external op-amps, filters or analogue calibration. For an engineer, it’s like having multiple error sources (analogue offset, amplifier drift, ADC matching) handled inside the device by the manufacturer during production calibration. That shortens debug time and eases PCB layout and power-supply cleanliness requirements, improving yield and consistency.

In a blood pressure monitor, readout accuracy directly affects trust in both clinical and home use. A high-precision pressure-sensing device reduces errors from the external signal chain. Because the sensor performs amplification, linearisation and calibration internally, the host MCU merely reads standardised digital codes and focuses on higher-level processing (such as Korotkoff sound detection and pressure-curve analysis). That simplifies the hardware and lets software tuning concentrate on algorithms rather than hardware compensation. Digital output also cuts analogue interference, improving repeatability in continuous measurements and statistical consistency in validation tests. For mass production, factory-level sensor calibration reduces per-unit calibration cost and improves batch uniformity, lowering after-sales variance and complaints.

2. Full-range coverage and high-resolution detection

Measurement range and resolution determine whether a sensor can capture the subtle pressure features that indicate systolic and diastolic points. The right pressure span must cover extreme low and high pressures, while fine resolution lets the system resolve tiny pressure fluctuations and pinpoint Korotkoff-related features.

How range and LSB resolution affect Korotkoff sound detection and repeatability

A good blood pressure monitor needs to operate reliably from around -50 to +360 mmHg and resolve changes finely across that span. A high-precision pressure sensor offering about 0.006 mmHg per LSB lets you clearly detect the onset, peaks and end points of Korotkoff sounds, improving repeatability and clinical agreement. In verification, engineers should run stepped-pressure injections and simulated blood-pressure waveforms to confirm linearity, sensitivity and dynamic response. On the algorithm side, a stable digital feed reduces reliance on heavy filtering or post-processing, which lets you speed up measurement and improve user experience. In short, wide range plus high sensitivity is the base requirement for both home and clinical devices.

3. Dual-channel redundancy and fault diagnostics for improved safety

For safety-focused blood-pressure devices, sensors that support dual-channel redundancy can spot gas-path anomalies or sensor failures quickly and trigger protection. This design significantly cuts the risk of dangerously wrong readings from single-point failures.

System-level benefits of built-in dual-channel monitoring and threshold comparison

Built-in dual sensing channels and diagnostic logic directly improve safety. In practice, two independent pressure paths are monitored simultaneously and compared either inside the sensor or by the MCU. If the difference exceeds a set threshold, the system can instantly vent and alert the user — avoiding hazardous overpressure. From a manufacturing and test perspective, you must calibrate both channels for consistency and run long-term drift tests to ensure comparability across the component’s lifetime. Engineering validation should include fault-injection trials to measure alarm latency, venting response time and the clarity of user alerts. Overall, redundancy shifts safety responsibility down to the sensor level, simplifying whole-system design and improving traceability for regulatory compliance.

4. Low power and package design impact on portability

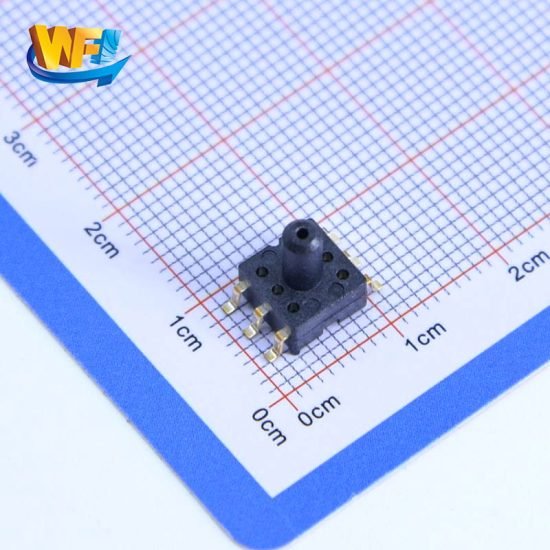

Portable home monitors need sensors that are compact yet robust; integrating the hose interface and sealing reduces external connections. Low-power running modes and sleep states are key to extending battery life.

How package size, hose interface and current specs affect battery life and device

For portable blood pressure monitors, device weight and battery life heavily influence user adoption. A compact sensor with an integrated hose interface reduces external tubing and leak risk while saving PCB area and assembly steps. Typical devices draw around 0.6 mA in active mode and drop to tens of nanoamps in sleep — crucial for battery-powered, handheld units. System-level design needs sensible wake-up logic to avoid frequent wake cycles that drain power. For packaging reliability, do thermal-cycling and mechanical-pull tests to confirm that the O-ring and hose interface keep a good seal over time. Ultimately, a low-power, small-package approach achieves lightweight, longer-lasting devices without compromising performance, improving user experience and market competitiveness.

5. Full-temperature-range compensation and stable output

Temperature shifts alter material behaviour and circuit parameters. Sensors that compensate internally across 0–50°C significantly reduce drift caused by environment or device heating, ensuring consistent readings.

Compensation strategies to keep readings consistent across environments

Temperature-compensated sensors sample internal temperature and apply correction coefficients to maintain stable output across environments — which matters a lot for both home and clinical settings. Engineering tests should span 0°C to 50°C on a test rig using reference instruments to measure zero-offset drift and range linearity at each temperature. Manufacturers typically bake compensation curves in at the factory, but you still need to validate whole-device performance once the sensor is integrated. If the device is used near heat sources or in rapidly changing conditions (outdoors or near hot electronics), provide thermal isolation or stabilisation in the mechanical design. Embedding temperature compensation in the sensor reduces whole-system sensitivity to environment and improves consistency — which builds user trust in the readings.

Hopena

Using digital MEMS pressure sensors in blood pressure monitors concentrates high accuracy, thermal stability and safety features into a single component. That simplifies system design, improves measurement consistency and strengthens fault response capabilities. Key engineering checkpoints are: verifying range and resolution, testing redundancy-channel consistency, optimising power and wake logic, and validating cross-temperature performance. For makers who prioritise device reliability and end-user confidence, choosing a sensor that ships with factory calibration and temperature compensation delivers tangible benefits across development time, production consistency and after-sales reliability.

ʻO ka mea i hōʻikeʻia ma luna nei e hōʻike wale ana i kaʻili o nā noi o kaʻenehanaʻo Sensor Sensor. E hoʻomau mau mākou i nāʻano likeʻole o nāʻano sensor i hoʻohanaʻia ma nā huahana likeʻole, pehea lākou e hana ai, a me kā lākou hanaʻana. Inā makemakeʻoe eʻoi aku ka nui o nā kiko'ī ma ka mea i kamaʻilioʻia ma aneʻi, hiki iāʻoe ke nānā i nāʻike pili ma hope o kēia alakaʻi. Ināʻoe e kaomi no ka manawa, hiki iāʻoe ke kaomi ma aneʻi e hoʻoiho i nā kiko'ī o kēia mau alakaʻi ʻO kaʻikepili o ka ea eʻike ai i kaʻikepili PDF. ^.

No nāʻike hou aku ma nāʻenehana loea'ē aʻe, eʻoluʻolu E kipa i kā mākouʻaoʻaoʻike. ^.