Catalóg

Modern diving equipment demands extreme pressure sensor performance, withstanding underwater high-pressure conditions while resisting long-term chloride and salt corrosion. Traditional sensors struggle with these challenges, while MEMS-based waterproof pressure sensors offer breakthrough solutions. These sensors feature unique gel-filled waterproof construction and shielded metal covers, achieving long-term stable operation in extreme environments.

1. MEMS Pressure Sensor Core Technology Architecture

Piezoresistive Sensing Principle Technical Advantages

MEMS piezoresistive pressure sensors utilize silicon micromachining technology to create miniature membrane structures. External pressure causes membrane deformation, changing resistive values converted to digital signals through high-precision ADCs. Compared to traditional capacitive sensors, piezoresistive designs offer lower temperature drift and higher long-term stability, perfectly suited for diving equipment’s harsh applications.

Advanced Packaging Processes Ensure Reliability

Modern MEMS pressure sensors employ innovative gel-filled packaging technology, injecting special silicone gel around sensor chips to create effective chemical barriers. This design prevents water and corrosive media from directly contacting sensitive elements while maintaining pressure transmission accuracy. Metal shielding covers further enhance mechanical strength and electromagnetic shielding performance.

Digital Interfaces Enable Precise Control

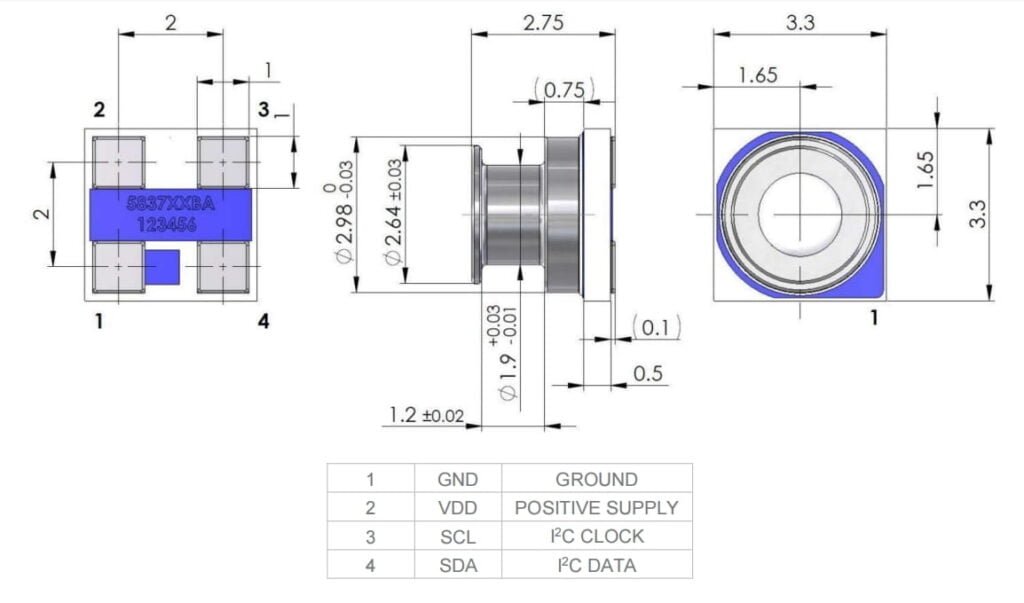

Integrated I2C digital interfaces allow direct microcontroller communication, eliminating analog signal transmission noise issues. 16-bit digital output resolution ensures high pressure measurement accuracy, while built-in temperature compensation algorithms effectively eliminate environmental temperature effects. This design enables diving equipment to achieve ±0.5mbar pressure measurement precision.

2. Harsh Environment Adaptability Design

Chlorine Chemical Corrosion Resistance

Swimming pools and seawater contain abundant chlorides and corrosive chemicals that cause electrochemical corrosion in traditional sensor metal components. Next-generation MEMS pressure sensors significantly extend service life in chlorinated environments through corrosion-resistant materials and surface treatments. Special chemical-inert coatings effectively block chloride ion erosion, ensuring stable performance in harsh chemical environments.

Waterproof Sealing Structure Design

IP68-grade waterproof design enables sensors to withstand water pressure exceeding 1-meter depth without leakage. Sealing structures employ multi-layer protection including O-ring seals, gel filling, and metal housing protection. This design ensures reliable underwater operation while withstanding repeated immersion-drying cycles without performance degradation.

Extreme Temperature Stability

Diving environments experience wide temperature ranges from tropical high temperatures to deep-sea cold conditions. MEMS pressure sensors achieve stable operation from -40°C to +85°C through built-in temperature sensors and advanced compensation algorithms. Temperature measurement accuracy reaches ±2°C, providing accurate environmental temperature information for diving equipment.

3. Ultra-Compact Design Meets Portable Requirements

Miniaturized Packaging Technology

Modern consumer diving equipment requires extremely high sensor integration levels. The ultra-small 3.3×3.3×2.75mm size enables easy integration into swim watches, fitness trackers, and other compact devices. This miniaturization saves valuable PCB space while reducing overall device weight and power consumption.

Low Power Operation Modes

Ultra-low power design with 0.1µA standby current significantly extends portable diving equipment battery life. Sensors employ intelligent power management, automatically entering sleep mode when measurements aren’t needed and quickly awakening for data acquisition. This design enables swim watches to achieve weeks or months of continuous operation.

Flexible Installation Interfaces

Standard surface-mount packaging simplifies production processes and reduces manufacturing costs. Four digital interface pins support standard I2C communication protocols, fully compatible with mainstream microcontrollers. This standardized design enables manufacturers to quickly integrate sensors, shortening product development cycles.

4. Precision Measurement System Integration

High-Resolution Pressure Detection

16-bit ADC converters provide 65536 quantization levels of measurement resolution, detecting minute pressure changes. This high-resolution design enables diving equipment to precisely measure depth changes, providing accurate depth information and safety warnings for divers. Sensor measurement ranges cover complete depth ranges from sea level to hundreds of meters underwater.

Real-Time Data Processing Capabilities

Built-in digital signal processing units execute filtering, temperature compensation, and calibration algorithms in real-time, outputting processed high-quality data. This design reduces main controller computational burden while improving overall system response speed. Data update frequencies reach 1kHz, meeting real-time monitoring application requirements.

Multi-Parameter Simultaneous Measurement

Sensors simultaneously provide pressure and temperature measurement data, achieving multi-functional detection through single devices. This integrated design reduces system complexity while improving measurement data synchronization and consistency. For diving equipment requiring precise depth calculations, synchronized pressure and temperature data are crucial.

5. Practical Application Performance Verification

Swim Watch Depth Monitoring

In swim watch applications, MEMS pressure sensors accurately measure swimmers’ depth changes in water, providing precise training analysis data. Sensor fast response characteristics capture subtle depth changes during swimming, helping athletes analyze techniques and improve training methods.

Professional Diving Equipment Integration

Professional dive computers require higher measurement accuracy and reliability, with MEMS pressure sensor ±0.5mbar precision fully meeting professional application needs. At typical 30-meter recreational diving depths, sensors provide centimeter-level depth resolution, ensuring reliable diving safety protection.

Underwater Unmanned Vehicle Applications

Underwater robots and unmanned underwater vehicles require long-term operation in harsh underwater environments. MEMS pressure sensor corrosion-resistant design and low power characteristics make them ideal choices. Digital interfaces simplify system integration while improving overall device reliability and maintenance convenience.

Conclúid

MEMS-based waterproof pressure sensors successfully solve traditional sensor technical challenges in harsh underwater environments through revolutionary design concepts and advanced manufacturing processes. With corrosion-resistant materials, ultra-compact packaging, low power design, and high-precision digital output capabilities, these sensors provide reliable depth measurement solutions for modern diving equipment, driving the entire industry toward higher precision and reliability.

Ní dhéanann an réamhrá thuas ach scratches ar dhromchla iarratais na teicneolaíochta braite brú. Leanfaimid orainn ag iniúchadh na gcineálacha éagsúla eilimintí braite a úsáidtear i dtáirgí éagsúla, conas a oibríonn siad, agus a gcuid buntáistí agus míbhuntáistí. Más mian leat tuilleadh sonraí a fháil ar a bhfuil pléite anseo, is féidir leat an t-ábhar gaolmhar a sheiceáil níos déanaí sa treoir seo. Má tá brú ama ort, is féidir leat cliceáil anseo freisin chun sonraí na dtreoracha seo a íoslódáil Sonraí PDF Táirge Braiteora Aeir Brú Aeir.

Le haghaidh tuilleadh eolais ar theicneolaíochtaí braiteora eile, le do thoil Tabhair cuairt ar ár leathanach braiteoirí.