Stable Pressure Output

Depth and temperature pressure sensors convert underwater absolute pressure into precise depth information through stable absolute-pressure output. Sensor packaging, temperature compensation, and digital output together ensure consistent data across varying sea conditions and temperatures, supporting depth calculation, ascent-rate alarms, and decompression-model inputs in dive computers.

Depth Measurement Principle and Accuracy Requirements

Pressure-to-Depth Conversion

The sensor measures absolute pressure in the water column. Depth is calculated from (water pressure − atmospheric pressure) ÷ (seawater density × gravitational acceleration). High-precision absolute-pressure readings, low temperature drift, and accurate surface-pressure initialization are directly tied to safe depth reporting. A sensor accuracy example of ±0.5% FS significantly reduces depth errors that could increase decompression risk.

Atmospheric Compensation and Algorithm Integration

Surface-Pressure Initialization and Data Fusion

Before a dive, the device initializes using surface atmospheric pressure; during the dive it continuously monitors absolute pressure and uses temperature data to adjust calculations for fluid density and gas consumption estimates. Sensor output feeds directly into decompression models (for example, Bühlmann/ZHL-type models) and ascent-rate checks, enabling live depth updates and triggering audible/visual alerts when safety thresholds are exceeded.

Hardware Design Points and Interface Requirements

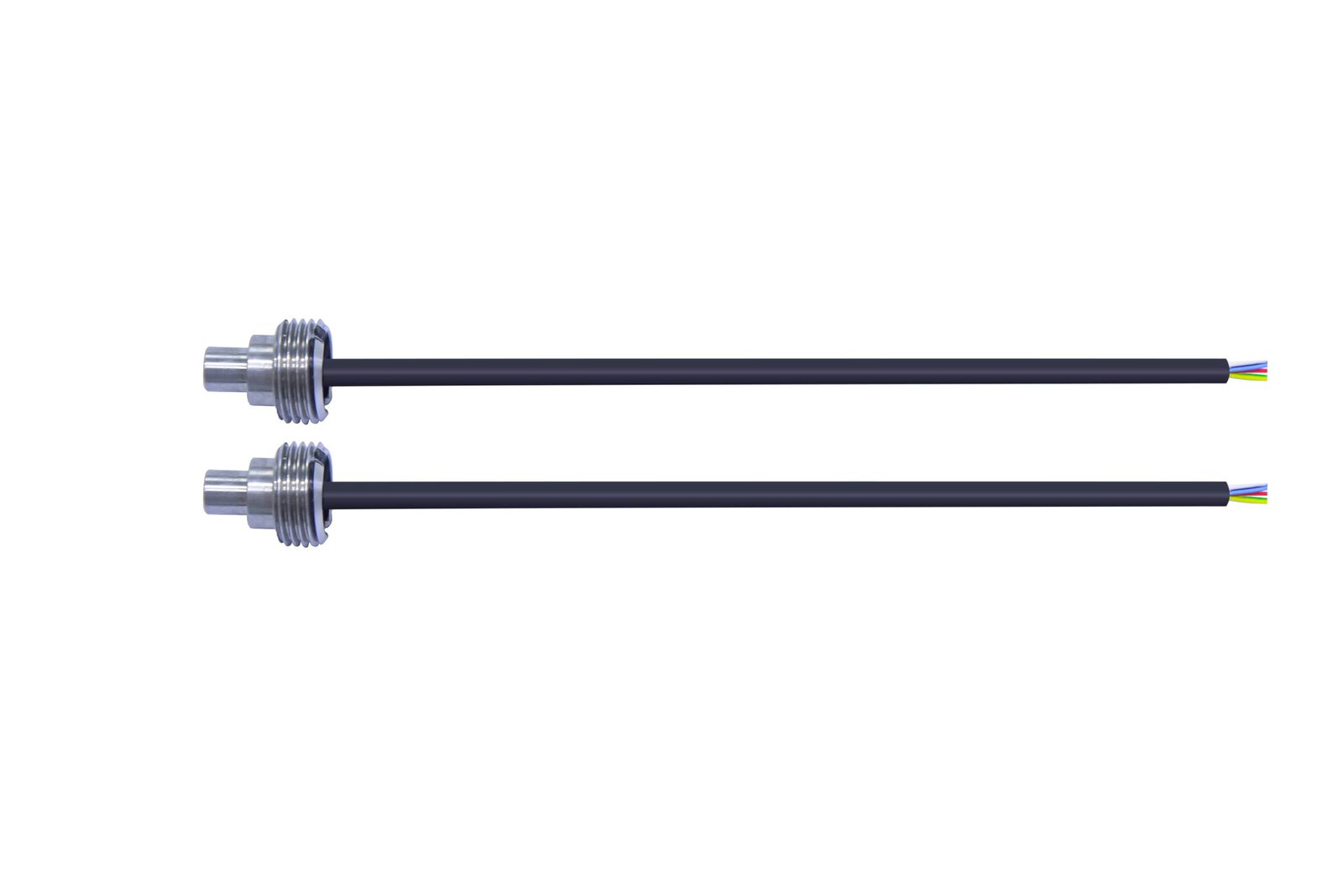

Packaging, Electrical, and Power Design

Sensors for dive computers are typically housed in 316L stainless steel and use oil-filled transmission to isolate the sensing element. They support sealed gauge and absolute pressure modes and cover ranges such as 6–30 psi for high-performance, low-pressure applications. Power range is 1.8–3.6 V, peak supply current is low (around 1.4–1.5 mA), and the device often outputs via a 24-bit DSADC over an I²C interface, allowing direct MCU integration and minimizing front-end analog filtering needs.

Calibration, Testing, and Reliability Verification

Calibration and Quality-Control Process

Production and maintenance should include factory temperature-compensation calibration, zero and span verification, temperature cycling, and long-term aging tests. Field procedures must allow surface initialization or use of a standard pressure source to correct atmospheric offset. Combining these routines with confidence scoring to filter suspect readings ensures dive computers maintain consistent measurement quality across repeated dives.

Key Takeaways

A high-reliability absolute-pressure sensor—sealed in 316L housings, oil-isolated, wide-range temperature compensated, and offering low-power digital output—is the core element for robust depth measurement in dive computers. Through careful electrical and mechanical design, precise factory calibration, and ongoing field checks, such sensors provide the trustworthy pressure data needed for depth calculation, decompression-model input, and ascent-rate alarms while balancing accuracy and battery life for portable underwater devices.

Ní dhéanann an réamhrá thuas ach scratches ar dhromchla iarratais na teicneolaíochta braite brú. Leanfaimid orainn ag iniúchadh na gcineálacha éagsúla eilimintí braite a úsáidtear i dtáirgí éagsúla, conas a oibríonn siad, agus a gcuid buntáistí agus míbhuntáistí. Más mian leat tuilleadh sonraí a fháil ar a bhfuil pléite anseo, is féidir leat an t-ábhar gaolmhar a sheiceáil níos déanaí sa treoir seo. Má tá brú ama ort, is féidir leat cliceáil anseo freisin chun sonraí na dtreoracha seo a íoslódáil Sonraí PDF Táirge Braiteora Aeir Brú Aeir.

Le haghaidh tuilleadh eolais ar theicneolaíochtaí braiteora eile, le do thoil Tabhair cuairt ar ár leathanach braiteoirí.