Introduction : Les baromètres sont de plus en plus utilisés dans les smartphones, les tablettes et les technologies portables, ouvrant la porte à de nouvelles applications industrielles telles que la surveillance précise de la position en hauteur et la maintenance prédictive. Alors, comment choisir le bon baromètre en fonction de vos exigences de conception ? À quels paramètres spécifiques devez-vous faire attention ? Quels détails techniques devez-vous prendre en compte lors de la sélection d’un produit ? Quelles sont les dernières combinaisons de baromètres ? Quelles sont les nouvelles orientations d’application des baromètres ? Grâce à cet article, j'espère que vous pourrez obtenir les informations nécessaires pour trouver le baromètre le plus idéal pour votre prochaine conception.

Découvrez 3 méthodes de mesure de pression et 4 techniques de fabrication, et choisissez celle qui convient à votre conception

Les baromètres sont utilisés pour détecter la pression atmosphérique des gaz ou des liquides. En tant que transducteur, les baromètres convertissent la pression atmosphérique appliquée en signaux de sortie analogiques ou numériques et sont généralement classés en fonction du type de mesure de la pression atmosphérique et de la technologie sensible à la pression.

Il existe trois façons de mesurer la pression atmosphérique :

Pression absolue : La pression absolue est la pression mesurée par rapport à un vide parfait. Si vous placez un baromètre absolu dans l'air, le capteur lira la pression atmosphérique réelle à cet endroit. Par conséquent, les baromètres absolus sont affectés par les changements d’altitude et de météo, etc.

Pression différentielle : La différence de pression atmosphérique mesurée entre deux sources de pression.

Pression relative : Lorsque l’une des sources de pression est la pression de l’air ambiant, la différence de pression mesurée est appelée pression relative.

Après avoir clarifié la méthode de mesure de pression, il est également nécessaire de réaliser que les différents principes utilisés dans la production de baromètres affecteront directement la précision, la portée, la taille du capteur et l'environnement applicable de la détection.

Voici les technologies sensibles à la pression les plus couramment utilisées :

■ Baromètre piézorésistif : utilise l'effet piézorésistif pour détecter le changement de résistance d'une ou plusieurs résistances montées sur le diaphragme lorsqu'une pression d'air est appliquée. Convient aux tests de pression généraux requis par l'Internet des objets, l'industrie et le médical.

■ Baromètre piézoélectrique : utilise les caractéristiques des matériaux piézoélectriques pour détecter la charge proportionnelle à la pression de l'air appliquée à la surface. Convient aux environnements à haute température, tels que la mesure de pression dynamique élevée sur les moteurs à réaction.

■ Baromètre capacitif : mesurez la pression atmosphérique en détectant le changement de capacité provoqué par le mouvement d'un diaphragme en verre, céramique ou silicium. Convient également aux tests de pression généraux requis par l'Internet des objets, l'industrie et le médical

■ Baromètre à fibre optique : utilise l'effet optique de la fibre optique. Convient aux environnements difficiles tels que le pétrole et le gaz, l'aérospatiale, la défense et le médical.

Comprendre les 8 paramètres clés d'un baromètre

Outre les principes de base du baromètre, vous devez également comprendre la signification des paramètres associés, qui constitue également la référence principale pour votre choix de baromètre :

Plage de pression ou étendue : La plage de pressions qu'un capteur peut mesurer. Le capteur’La tolérance de surpression, qui correspond à la pression maximale à laquelle l'appareil peut résister et continuer à fonctionner lorsque le baromètre revient dans la plage de fonctionnement, doit également être prise en compte.

Précision: La précision absolue indique à quel point la sortie du baromètre est proche de la pression réelle. Elle s'exprime comme la différence entre deux valeurs. La précision relative est l'erreur entre deux mesures.

Conditionnement: Déterminé par l’environnement de l’application finale et les contraintes de taille. Les petits emballages étanches sont souvent préférés.

Bruit: En termes simples, il s'agit de la variation aléatoire de la sortie du capteur liée aux changements de l'entrée du capteur.

Décalage du coefficient de température : Également connu sous le nom de coefficient de température de pression nulle. Il représente le changement de décalage à pression nulle en raison de la température, donc plus il est petit, mieux c'est.

Débit de données de sortie : Taux auquel les données sont échantillonnées.

Bande passante : Le signal de fréquence la plus élevée pouvant être échantillonné sans alias.

Consommation d'énergie : La consommation d'énergie est extrêmement importante pour les applications qui fonctionnent avec de petites batteries et celles qui doivent préserver autant que possible la durée de vie de la batterie. La consommation électrique est étroitement liée au choix de l'ODR et de la résolution. Le bruit RMS du baromètre est également lié à la bande passante et à la résolution. La consommation d'énergie et la résolution doivent donc être pondérées en fonction des exigences d'application du capteur. Bien entendu, il existe d'autres paramètres, tels que la tension d'alimentation, la température de fonctionnement, la portée, l'interface de communication, etc.

Relation entre la pression atmosphérique et l'altitude

Voici les unités de mesure de la pression atmosphérique :

Psi – livres par pouce carré

Cm/Hg – centimètres de mercure

Cm/Hg – pouces de mercure

Pa – Pascal, unité SI de pression, 1Pa = 1 N/m2

Bar – bar, unité de pression atmosphérique, 1 bar = 105Pa

Mbar – millibar, 1mbar = 10-3 bar

Nous vivons dans les profondeurs de la Terre’s atmosphère, où la pression atmosphérique diminue à mesure que l'altitude augmente. Nous définissons la pression atmosphérique standard comme 29,92 po/Hg au niveau de la mer à 59°F, une valeur moyenne qui n'est pas affectée par le temps mais par l'emplacement géographique du point de mesure, la température et les courants d'air.

Par conséquent, la relation de conversion entre les unités de pression ci-dessus est :

1 atmosphère standard = 14,7 psi = 76 cm/Hg = 29,92 po/Hg = 1,01325 bar = 1013,25 mbar

La relation entre la pression atmosphérique et l’altitude peut s’exprimer comme suit[1] :

Où:

P0 est la pression atmosphérique standard, égale à 1013,25 mbar ;

L'altitude est l'altitude en mètres.

P est la pression atmosphérique en mbar à une certaine altitude

La figure 1 décrit la relation entre le changement de pression atmosphérique et l'altitude sur la base de la formule ci-dessus.

Comme le montre la figure, lorsque l'altitude monte du niveau de la mer à 11 000 mètres au-dessus du niveau de la mer, la pression atmosphérique chute de 1 013,25 mbar à 230 mbar. Il n'est pas difficile de voir sur la figure que lorsque l'altitude est inférieure à 1 500 mètres, la pression atmosphérique diminue de manière presque linéaire, avec une diminution d'environ 11,2 mbar pour 100 mètres, soit environ 1,1 mbar pour 10 mètres. Afin d'obtenir des données de mesure d'altitude plus précises, une table de requête d'altitude à pression atmosphérique peut être créée dans l'application cible pour déterminer l'altitude correspondante sur la base des résultats de mesure du capteur de pression.

Si un capteur de pression absolue MEMS avec une plage complète de 300 mbar à 1 100 mbar est utilisé, l'altitude de mesure peut atteindre 9 165 mètres au-dessus du niveau de la mer à 698 mètres au-dessous du niveau de la mer.

Exemple d'application : Détermination du niveau du sol à l'aide de capteurs MEMS

La résolution de mesure de 0,1 mbar (10 Pa) /rms permet Capteurs de pression MEMS pour détecter les changements de hauteur dans un rayon de 1 mètre. Par conséquent, dans les immeubles de grande hauteur, des capteurs de pression peuvent être utilisés pour détecter les changements dans les étages.

Deuxièmement, des stations de surveillance d'altitude sont déployées à plusieurs endroits dans la région pour mesurer la pression atmosphérique locale, corriger les conditions météorologiques et d'autres facteurs d'influence, créer une lecture d'altitude de haute précision, puis déterminer la hauteur exacte du sol de l'appareil, apportant ainsi de nouvelles capacités de géolocalisation.

La figure 2 montre les données du capteur de pression collectées dans STMicroelectronics’ Immeuble de bureaux Castelletto en Italie. Le taux d'échantillonnage est de 7 Hz et la durée de collecte des données est d'environ 23 minutes au total. Sur la figure, nous pouvons clairement voir les changements de pression atmosphérique aux différents étages. C'est au sous-sol que la pression atmosphérique est la plus élevée. Au fur et à mesure que les étages montent, la pression atmosphérique diminue progressivement.

Pour les environnements urbains complexes comportant des bâtiments à plusieurs étages, la technologie GPS actuelle ne peut pas fournir de données de position tridimensionnelles fiables. Mais l'application des baromètres est devenue une nouvelle solution conçue sur la base du changement de pression atmosphérique. – lorsqu'une personne atteint une certaine hauteur, la pression de l'air diminue.

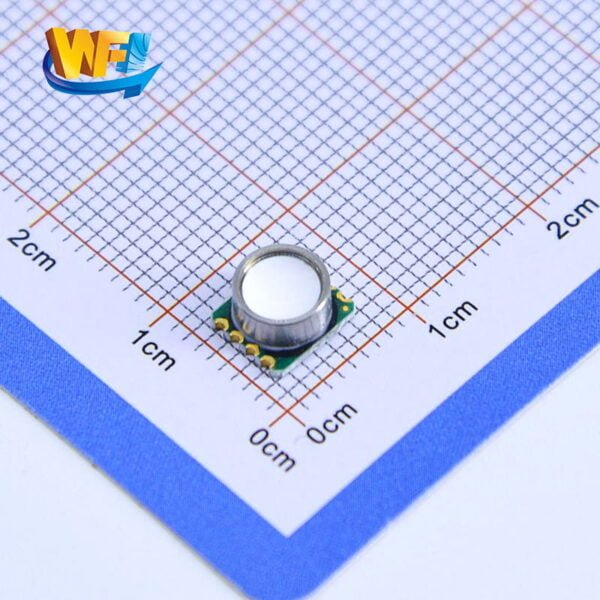

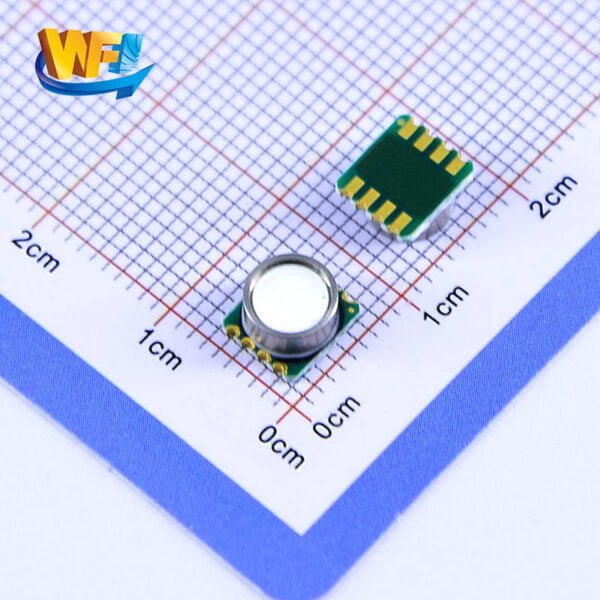

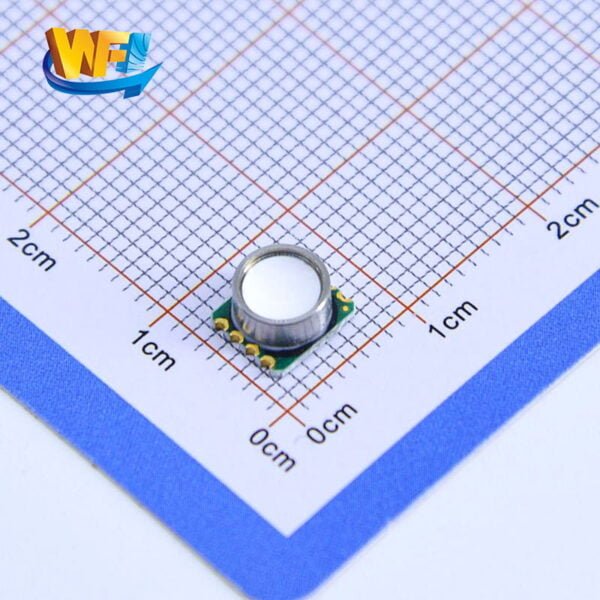

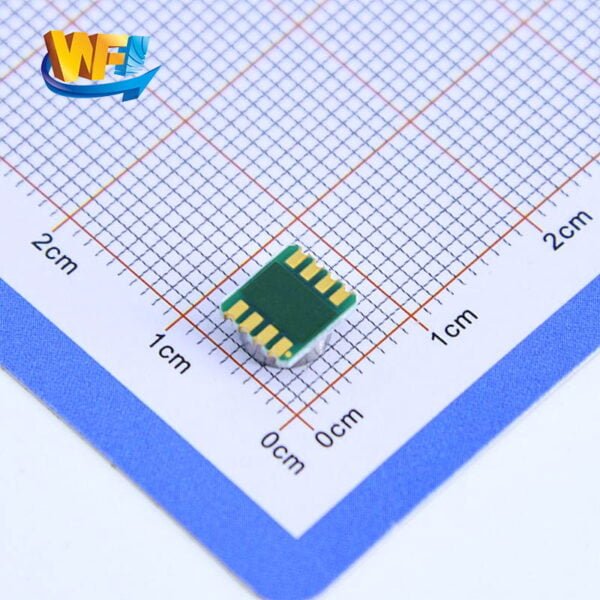

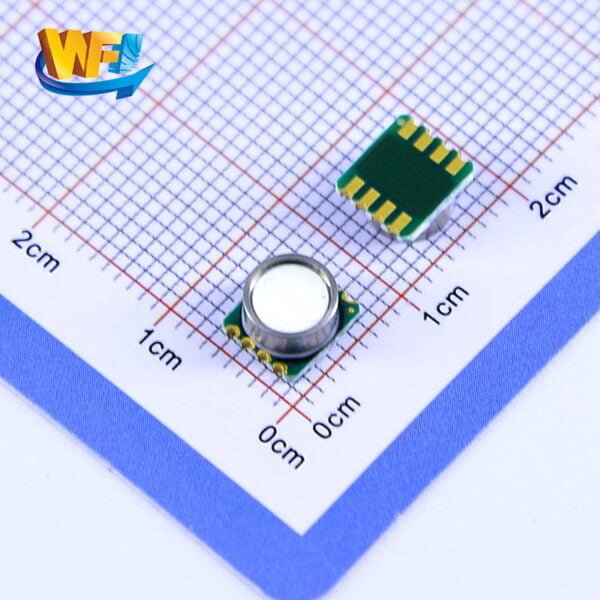

Comme le montre la figure ci-dessous, dans cette solution, tout d'abord, l'appareil portable ou le téléphone mobile doit disposer d'un capteur barométrique de haute qualité, tel que : WF5803F, 5803C/WF280A, etc., ou des capteurs de pression d'air industriels WF5805F et 5837, avec un taux d'échantillonnage de 3 kHz et un temps total de collecte de données d'environ 3 ms.

WFsensors fournit une variété de capteurs barométriques piézorésistifs avec une large gamme de modèles de produits, y compris des types de pression absolue non étanches et étanches à pression absolue, adaptés à de nombreux produits terminaux intelligents tels que les téléphones mobiles, les drones, les appareils portables, les montres/bracelets, les montres de sport, etc. Il est utilisé comme altimètre, ainsi que comme indicateur pour les prévisions météorologiques et la surveillance de l'humidité et de la température de l'environnement.

C'est une phrase remarquable et très précieuse

whoah, ce blog est excellent, j'aime lire vos articles. Continuez votre bon travail ! Vous l’avez compris, de nombreuses personnes recherchent ces informations, vous pouvez grandement les aider.

C'est intéressant. Vous ne me demanderez pas où puis-je lire à ce sujet ?