Modern vacuum pumps are no longer confined to merely generating suction—they are evolving toward smart, precise control. By integrating high-accuracy pressure sensors, vacuum pump systems can monitor negative pressure in real time and dynamically adjust output, ensuring stable operation and accurate measurement while minimizing equipment risks. This article delves into how vacuum pump pressure sensors, such as those in the Série WF100E, harness advanced technology to achieve high-accuracy negative pressure measurement, revolutionizing applications in industrial, medical, and IoT environments.

Catalogue

Comment fonctionne le capteur de pression

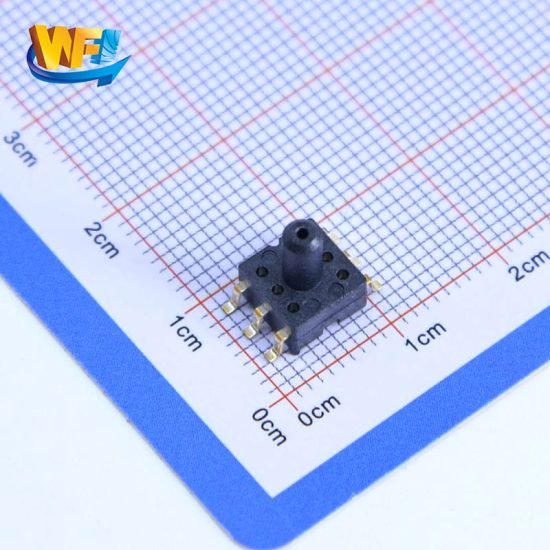

The core of a vacuum pump is its ability to generate and maintain stable negative pressure, a task that demands precise pressure measurement. The WF100E series sensors employ cutting-edge MEMS technology coupled with CMOS mixed-signal processing to ensure that every measurement meets high accuracy standards. Key aspects of their operation include:

Surveillance de la pression en temps réel

The sensor converts physical pressure into an electrical voltage signal, with a standard output range of 0.2–4.7V. Using the formula

Il calcule avec précision la pression négative.

Compensation de température et stabilité à long terme

Operating over a wide temperature range from -40°C to 125°C, the sensor maintains high linearity (≤0.5% FS error) and low zero drift (±0.03 FS/°C), ensuring reliable performance under varying environmental conditions.

Conditionnement du signal et transmission de données

An integrated signal conditioning ASIC amplifies and corrects the raw signal, transmitting the data via standard interfaces (such as I2C or SPI) to the control system for dynamic negative pressure regulation.

L'importance du contrôle intelligent de la pression négative

In many applications, negative pressure measurement affects not only the efficiency of a system but also its safety and user comfort:

Contrôle de précision

With real-time data feedback, the vacuum pump can automatically adjust suction to maintain negative pressure within an optimal range, avoiding issues caused by excessive or insufficient suction.

Efficacité améliorée du système

Dynamic suction adjustment leads to more responsive operations, shorter working cycles, reduced energy consumption, and longer equipment lifespan.

Gestion des données intelligentes

When combined with IoT technology, sensors can transmit real-time data to cloud platforms, enabling users or technicians to analyze and optimize operating parameters for smarter manufacturing and remote monitoring.

Le rôle des capteurs de pression dans les systèmes de pompe à vide

Pressure sensors play a critical role in vacuum pump systems, with key benefits including:

Surveillance en temps réel des changements de pression négatifs

Accurately measuring every pressure fluctuation provides a reliable data foundation for the system.

Ajustement d'aspiration automatique

Based on real-time data, the system can quickly modulate suction to keep negative pressure within a preset range, enhancing overall stability.

Journalisation des données et gestion à distance

With visualization platforms, users can track historical data, analyze system performance, and proactively address potential issues.

Ingénierie et maintenance optimisées

High integration reduces circuit complexity, simplifying system design and streamlining maintenance efforts.

Detailed Operating Parameters of Vacuum Sensors (Supplementary)

Building on the overall system role, vacuum sensors must also meet a series of strict engineering requirements to ensure that vacuum pumps operate reliably and efficiently under various conditions. Specifically, the sensors are designed with the following features:

Pressure Measurement Range:

Généralement conçu pour fonctionner dans une gamme de -100kPa to 0kPa, ensuring coverage for most vacuum pump applications.

Précision:

Le capteur maintient une erreur à grande échelle dans ± 1% span, coupled with low zero drift (± 0,03 fs / ℃) to deliver long-term high accuracy measurements.

Resolution:

By leveraging the standard output range of 0.2–4.7V and the conversion formula, each incremental voltage change corresponds to subtle pressure variations, allowing the sensor to effectively detect even minor fluctuations (0.001kPa Resolution).

Response Rate:

Utilizing advanced MEMS technology and integrated signal conditioning, the sensor offers rapid 1ms response capabilities to capture real-time pressure changes, meeting dynamic load requirements and enabling swift suction adjustments.

Operating Temperature Compensation:

With a robust operating range from -40°C to 125°C, the sensor’s built-in temperature compensation mechanism minimizes the impact of temperature fluctuations on measurement accuracy, ensuring high linearity and precision in diverse environments.

Conclusion

The integration of pressure sensors in vacuum pump systems is driving a shift from conventional suction control to smart, precision management. Represented by the WF100E series, high-precision sensors excel in real-time measurement, automatic adjustment, and temperature compensation, offering safe, efficient, and intelligent solutions across various industries. As technology advances, we can expect these smart systems to play an even greater role in industrial automation, healthcare, and IoT applications—setting new benchmarks for innovation and reliability.

L’introduction ci-dessus ne fait qu’effleurer la surface des applications de la technologie des capteurs de pression. Nous continuerons à explorer les différents types d’éléments capteurs utilisés dans divers produits, leur fonctionnement ainsi que leurs avantages et inconvénients. Si tu’D Like plus de détails sur ce’Comme discuté ici, vous pouvez consulter le contenu associé plus loin dans ce guide. Si vous êtes pressé par le temps, vous pouvez également cliquer ici pour télécharger les détails de ce guide Données PDF du produit du capteur de pression d'air.

Pour plus d'informations sur d'autres technologies de capteurs, veuillez Visitez notre page de capteurs.