Pressure measurement is fundamental to countless industrial applications, from manufacturing processes to scientific research. This guide demystifies the relationship between absolute pressure and vacuum pressure, providing practical insights for selecting and using pressure measurement instruments effectively. We’ll explore what happens when measuring vacuum conditions and how absolute pressure sensors function in these environments.

Catalogue

Introduction à la mesure de la pression

Pressure measurement is essential in numerous industries and applications. From ensuring safety in pressure vessels to optimizing process efficiency, proper pressure monitoring can mean the difference between smooth operations and catastrophic failures. However, to effectively utilize pressure measurements, you must first understand the different pressure types and how they relate to one another

In the pressure instrumentation industry, confusion between absolute, gauge, and vacuum pressure is remarkably common. This confusion often leads to incorrect gauge selection, misinterpretation of readings, and ultimately, process inefficiencies or safety concerns.

Pressure is fundamentally defined as force per unit area. However, how we measure and reference this force creates different pressure types. The reference point we choose is critically important – it changes not just the numbers we see, but how we interpret and use those measurements

Before diving deeper into absolute pressure in vacuum systems, it’s essential to establish a solid foundation regarding the basic pressure types and their reference points. This understanding will serve as the groundwork for more complex discussions throughout this article.

What is Absolute Pressure?

La pression absolue se réfère à la pression mesurée par rapport à la pression nulle absolue – a perfect vacuum where no molecules exist to exert any pressure. This concept is fundamental to understanding all pressure measurements since it provides an unchanging reference point

At sea level, the standard atmospheric pressure is approximately 14.7 psi (pounds per square inch) or 101.325 kPa (kilopascals) in absolute terms. This means that even when a standard pressure gauge reads « zero, » nous’re actually experiencing about 14.7 psi of pressure from the atmosphere around us

The key characteristic of absolute pressure is that it can never be negative. Since it’s referenced to perfect vacuum (which is zero), all absolute pressure readings must be positive. Even in the deepest vacuum we can create with modern technology, there are still some molecules present, exerting a tiny amount of pressure.

Absolute pressure (Pabs) can be mathematically expressed as:

Pabs = Pgauge + Patmospheric

Où:

Pgauge est la lecture de pression sur une jauge standard

Patmospheric is the local atmospheric pressure (approximately 14.7 psi at sea level)

Il’s worth noting that atmospheric pressure varies with altitude and weather conditions. At higher elevations, atmospheric pressure decreases significantly. Weather systems can also cause barometric pressure to fluctuate, which can impact absolute pressure readings if not accounted for

Comprendre la pression de vide

Vacuum pressure represents a pressure lower than the surrounding atmospheric pressure. In practical terms, it’s a negative gauge pressure, indicating suction or the « tirage » Effet que nous associons aux aspirateurs

When discussing vacuum pressure, it’est important de reconnaître que nous’re still using atmospheric pressure as our reference point. A perfect vacuum would register as -14.7 psi on a gauge pressure scale at sea level (or whatever the local atmospheric pressure happens to be)

Vacuum pressure is typically measured in different units than positive pressure, adding another layer of potential confusion. Common vacuum units include:

Inches of mercury (inHg)

Torr (1 Torr = 1 mmHg)

Microns (1 micron = 0.001 Torr)

Pourcentage de vide

The relationship between vacuum pressure and absolute pressure is straightforward but often misunderstood. A complete vacuum (though practically unachievable) would register as:

0 psia (absolute pressure)

-14.7 psig (gauge pressure at sea level)

30 inHg vacuum (inches of mercury)

In industrial applications, vacuum pressures are commonly used in processes like distillation, filtration, freeze drying, and packaging. Each application has specific vacuum requirements, making proper measurement crucial.

Relation entre la pression absolue et l'aspirateur

The relationship between absolute pressure and vacuum pressure is fundamental to understanding pressure measurement systems. As mentioned earlier, they’re essentially different ways of describing the same physical reality, just with different reference points

Laisser’s clarify this relationship with some examples:

A perfect vacuum (theoretically):

Absolute pressure: 0 psia

Vacuum pressure: 30 inHg (at sea level)

Atmospheric pressure at sea level:

Absolute pressure: 14.7 psia

Vacuum pressure: 0 inHg

50% vacuum at sea level:

Absolute pressure: approximately 7.35 psia

Vacuum pressure: 15 inHg

The mathematical relationship can be expressed as:

Pabsolute = patmosphérique – Pvacuum

Où pvacuum est exprimé dans les mêmes unités que patmosphériques

Il’est important de noter que même si nous parlons généralement de « vacuum pressure, » this term can be misleading since vacuum actually represents the absence of pressure. More precisely, what we call vacuum pressure is the pressure differential between the system and the surrounding atmosphere.

When validating containment systems in pharmaceutical clean rooms, understanding that what we’re measuring is really a pressure differential rather than an absolute vacuum helps technicians properly set up monitoring equipment and interpret results correctly.

How Does an Absolute Pressure Sensor Work?

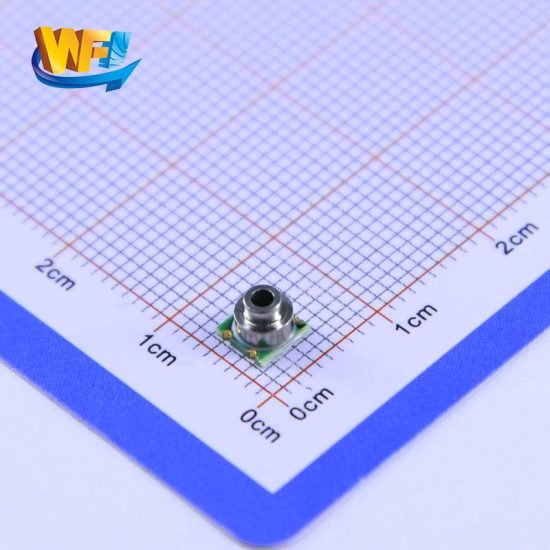

Absolute pressure sensors are specialized instruments designed to measure pressure relative to perfect vacuum. Unlike gauge pressure sensors that use atmospheric pressure as a reference, absolute pressure sensors use a sealed reference chamber containing either a high vacuum or a known reference pressure

The basic working principle of an absolute pressure sensor involves:

A sensing element (diaphragm, bellows, or Bourdon tube) that deforms under pressure

Une chambre de référence scellée évacuée vers un vide presque parfait

Un mécanisme pour convertir la déformation mécanique en un signal électrique

Composants électroniques pour le traitement du signal et la génération de sortie

Modern absolute pressure sensors typically use one of several technologies:

Piezoresistive sensors: These contain a silicon diaphragm with embedded resistors that change resistance when the diaphragm deforms under pressure. They’re common in industrial applications due to their robustness and accuracy.

Capacitive sensors: These measure pressure by detecting changes in capacitance between a flexible diaphragm and a fixed plate as pressure changes. They excel in low-pressure applications requiring high sensitivity.

Resonant sensors: These measure pressure by detecting changes in the resonant frequency of a vibrating element as pressure changes. They offer excellent stability and accuracy but at a higher cost.

Optical sensors: These use light interaction with a pressure-sensitive element to determine pressure. They’re ideal for environments with electromagnetic interference.

For vacuum measurement specifically, specialized vacuum gauges like thermocouple gauges, ionization gauges, or Pirani gauges may be used for very low pressures where standard absolute pressure sensors might lack resolution.

When monitoring vacuum chambers for vapor deposition in semiconductor manufacturing, ionization gauges provide the precision needed at extremely low pressures (below 10^-3 Torr), while capacitive sensors work better for the higher-pressure stages of the process.

Applications de la mesure de la pression absolue

Absolute pressure measurement plays a crucial role across numerous industries and applications. Understanding when and why absolute pressure measurement is necessary can help you make better decisions in your specific context

Here are some key applications where absolute pressure measurement is particularly important:

Prévisions météorologiques et altimétrie

Barometric pressure, measured as an absolute pressure, is fundamental to weather prediction. Meteorologists track these pressure changes to predict weather patterns and storms. Similarly, altimeters in aircraft use absolute pressure measurements to determine altitude based on the relationship between pressure and elevation.

Traitement et emballage de l'aspirateur

Industries like food packaging, pharmaceutical production, and semiconductor manufacturing rely heavily on vacuum processes. Absolute pressure sensors ensure precise vacuum levels are maintained for product quality and process efficiency1.

For example, in food packaging, maintaining the correct vacuum level is essential for extending shelf life. Too little vacuum might allow spoilage, while excessive vacuum could damage delicate products.

Systèmes de CVC et réfrigération

Heating, ventilation, air conditioning, and refrigeration systems use absolute pressure measurements to monitor refrigerant pressures, optimize compressor operation, and ensure system efficiency. The relationship between pressure and temperature in refrigerants makes absolute pressure monitoring critical for these systems.

Recherche en laboratoire

Scientific research often requires precise control and measurement of pressure conditions. From chemical vapor deposition to vacuum distillation, absolute pressure measurements provide researchers with the data needed for reproducible experiments and accurate results.

Aérospatial et aviation

Beyond altimetry, aerospace applications require absolute pressure measurements for engine performance monitoring, cabin pressurization systems, and testing components under various pressure conditions. The extreme operating environments in aerospace make reliable absolute pressure measurement essential for safety and performance.

In critical medical breathing apparatus, absolute pressure sensors ensure consistent therapy delivery whether the device is used at sea level or in high-altitude locations, as the measurements remain consistent regardless of ambient atmospheric conditions.

Choisir le bon manomètre pour vos besoins

Selecting the appropriate pressure gauge or sensor is crucial for accurate measurements and optimal process control. The choice between absolute, gauge, or compound pressure instruments depends on your specific application requirements.

Quand utiliser des manomètres absolus

Consider using absolute pressure instruments when:

Vous avez besoin de mesures indépendantes des fluctuations de la pression atmosphérique

Votre application implique des processus de vide où la référence à un vide parfaite est importante

Toi’RETAGNE avec des systèmes scellés où la référence atmosphérique n'est pas’t disponible

Your measurements need to be comparable across different altitudes or weather conditions.

Quand utiliser les manomètres

Vacuum gauges are most appropriate when:

Toi’concernant principalement le niveau de vide par rapport à l'atmosphère

Votre processus fonctionne entièrement en dessous de la pression atmosphérique

Vous devez visualiser le niveau de vide dans des unités familières comme des pouces de mercure

Toi’Repannage des systèmes d'aspirateur ou détection des fuites

Common applications include HVAC service, vacuum pumping systems, vacuum packaging, and filtration processes.

Considérations de sélection pratiques

Beyond the type of pressure measurement, consider these factors when selecting pressure instruments:

Accuracy requirements: How precise must your measurements be?

Pressure range: What are the minimum and maximum pressures you need to measure?

Environmental conditions: Temperature, humidity, vibration, and corrosive elements

Output requirements: Do you need local display, electrical output, or both?

Safety requirements: Overpressure protection, intrinsically safe design for hazardous areas

Budget constraints: Balance performance needs with cost considerations.

In fermentation process optimization at breweries, using absolute pressure sensors instead of standard gauge pressure sensors can eliminate variations caused by barometric pressure changes, resulting in improved batch consistency.

Conclusion

Understanding the relationship between absolute pressure and vacuum pressure is essential for proper measurement, interpretation, and application in industrial processes. To summarize the key points:

Absolute pressure is measured relative to perfect vacuum (zero pressure) and can never be negative

La pression de vide est mesurée par rapport à la pression atmosphérique et représente la pression en dessous de l'atmosphère

La pression absolue dans un système de vide est égale à la pression atmosphérique moins la pression de vide

Différentes applications nécessitent des types de mesure de pression différents – absolute, gauge, vacuum, or compound

Selecting the appropriate pressure instrument depends on your specific application needs and environmental conditions.

Si vous’re designing vacuum systems, troubleshooting pressure-related issues, or optimizing industrial processes, a clear understanding of these pressure concepts will improve your decision-making and results.

Remember that while modern pressure instrumentation is highly sophisticated, the foundational concepts remain straightforward – il’s all about choosing the right reference point for your measurements and understanding how different pressure types relate to each other.

As technology advances, we’re seeing exciting developments in pressure measurement technology, including wireless connectivity, integrated temperature compensation, and smart diagnostics. These innovations are making pressure measurement more accurate, convenient, and integrated with broader process control systems than ever before.

L’introduction ci-dessus ne fait qu’effleurer la surface des applications de la technologie des capteurs de pression. Nous continuerons à explorer les différents types d’éléments capteurs utilisés dans divers produits, leur fonctionnement ainsi que leurs avantages et inconvénients. Si tu’D Like plus de détails sur ce’Comme discuté ici, vous pouvez consulter le contenu associé plus loin dans ce guide. Si vous êtes pressé par le temps, vous pouvez également cliquer ici pour télécharger les détails de ce guide Données PDF du produit du capteur de pression d'air.

Pour plus d'informations sur d'autres technologies de capteurs, veuillez Visitez notre page de capteurs.

Absolutely with you it agree. In it something is also idea good, I support.

This post is another great example of why your blog stands out — it’s honest, curious, and clearly made with care.