Les capteurs de pression MEMS permettent la navigation 3D en surveillant les changements de pression atmosphérique, convertissant le guidage GPS plan en positionnement spatial. Ces capteurs mesurent les variations barométriques pour calculer l'altitude, comblant ainsi les angles morts verticaux du GPS dans les canyons et tunnels urbains où les signaux satellite échouent.

Catalogue

1. Why Automotive Navigation Needs Altitude Sensing

1.1 GPS Vertical Positioning Gaps

GPS achieves 3-5m horizontal accuracy but suffers 10-15m vertical errors due to satellite geometry. In urban environments, multipath interference degrades altitude data completely. Automotive navigation pressure sensors provide independent altitude references by measuring atmospheric pressure.

1.2 Overpass & Tunnel Scenario Demands

Identical GPS coordinates may represent surface roads, elevated decks, or underground passages. Without altitude data, navigation systems cannot determine vehicle levels. Altimeter pressure sensors distinguish ±1m elevation differences, critical for identifying bridge levels and tunnel entries.

1.3 Barometric Measurement Fills Positioning Shortfalls

Pressure drops ~1 hPa per 8.3m elevation gain. High-resolution pressure sensors deduce altitude changes from precise barometric measurements. Kalman fusion with GPS elevation achieves 3-5× better accuracy than single-source data, maintaining continuous vertical sensing even when satellite signals vanish.

2. MEMS Pressure Sensor Core Mechanisms

2.1 Atmospheric Pressure to Altitude Conversion Logic

Sensors employ International Standard Atmosphere models: H = 44330 × [1 – (P/P₀)^0.1903], where P is current pressure and P₀ is sea-level reference (1013.25 hPa at 15°C). Systems adjust P₀ using real-time meteorological data, eliminating weather-induced pressure fluctuations through dynamic calibration.

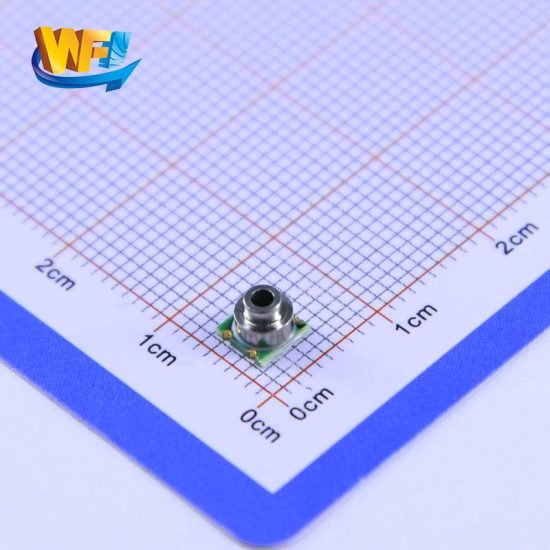

2.2 Silicon Membrane Deformation & Signal Conversion

MEMS micromachining fabricates micron-thick pressure-sensitive membranes on silicon wafers. Atmospheric pressure induces elastic deformation, converted to resistance changes by piezoresistive elements, then to voltage via Wheatstone bridges. Fully integrated chips output digitized pressure data directly.

2.3 Temperature Compensation & Digital Calibration

Uncompensated sensors produce hundreds of pascals error across -40°C to +125°C automotive ranges. Digital output sensors integrate temperature monitors, storing factory calibration coefficients in non-volatile memory. Embedded processors apply real-time compensation algorithms, achieving ±0.5 hPa absolute accuracy (±4m altitude equivalent).

3. Digital Interfaces & Intégration du système

3.1 I²C vs SPI Protocol Selection

Embedded pressure sensors equip I²C (two-wire: SCL, SDA) or SPI (four-wire: SCLK, MOSI, MISO, CS) interfaces. I²C’s 100-400 kHz rates satisfy 1-10 Hz navigation updates with simple wiring. SPI’s tens-of-MHz speeds suit high sampling rate sensors. I²C gains preference for multi-device compatibility and flexible mounting.

3.2 Real-Time Data Processing in Embedded Systems

Microcontrollers configure sensor registers for measurement modes and sampling rates (1-10 Hz typical, up to 1 kHz capable). 24-bit calibrated data outputs in pascals/hectopascals. Hosts time-sync barometric data with GPS/IMU, feeding Kalman filters that assign sensor weights based on signal strength—prioritizing GPS when strong, elevating barometric weight in weak zones.

4. Accuracy & Stability: Key Performance Metrics

4.1 Absolute vs Relative Accuracy Practical Significance

Absolute accuracy (±0.5 hPa typical) determines actual altitude calculation capability. Relative accuracy (±0.1 hPa in premium units) reflects change detection sensitivity—distinguishing ~0.8m elevation differences. Navigation systems prioritize relative accuracy for tracking uphill/downhill driving and tunnel entry, not precise sea-level elevation.

4.2 High Resolution Achieves Meter-Level Measurement

16-bit ADCs spanning 300-1100 hPa represent ~0.012 hPa per count (~0.1m altitude). 24-bit ADCs boost resolution to 0.00005 hPa (centimeter-scale theoretically). Digital filters suppress noise, elevating usable resolution to 0.8-1m—sufficient to differentiate surface roads from elevated bridges and tunnel entries/exits.

4.3 Long-Term Drift & Adaptabilité environnementale

Quality MEMS sensors specify ±0.5 hPa/year stability (±4m altitude equivalent annually). Gel packaging isolates moisture while preserving pressure paths. -40°C to +125°C operating ranges cover arctic to engine compartment environments. Anti-vibration design prevents false signals during rough-road driving.

5. Real-World Performance

5.1 Multi-Level Road Recognition Capability

In complex urban interchanges, identical GPS coordinates may represent ground, second-tier, or third-tier loop roads. Pressure sensors add physical constraints for level identification—detecting pressure drops during ramp ascents, stabilization upon reaching elevated platforms. Testing shows altitude-integrated navigation achieves 40%+ higher accuracy than pure GPS in overpass scenarios.

5.2 Continuous Tunnel Positioning Assurance

GPS signals vanish in long tunnels while inertial systems diverge from accumulated errors. Altimeter pressure sensors become sole reliable vertical positioning means. Monitoring pressure change rates, systems deduce vehicle travel distance/direction inside tunnels, maintaining <10m relative accuracy until GPS signal recovery enables smooth transitions.

5.3 Energy Optimization & Range Management

Electric vehicle consumption correlates with altitude variations—climbing requires extra energy, descending enables regenerative recovery. Navigation systems integrating altimeter pressure sensors calculate route ascent/descent totals, estimating consumption differences. Altitude-aware planning reduces mountain-driving energy use by 5-12%. Ultra-low power (<3μA standby) negligibly impacts overall vehicle consumption.

Conclusion

From Planar to 3D, Safeguarding Precise Positioning MEMS pressure sensors inject vertical sensing into automotive navigation through precise atmospheric pressure measurement. Silicon micromachining converts subtle pressure changes to accurate digital signals, with temperature compensation ensuring all-condition stability. Meter-level resolution and millisecond response enable real-time tracking of vehicle transitions within 3D road networks.

L’introduction ci-dessus ne fait qu’effleurer la surface des applications de la technologie des capteurs de pression. Nous continuerons à explorer les différents types d’éléments capteurs utilisés dans divers produits, leur fonctionnement ainsi que leurs avantages et inconvénients. Si tu’D Like plus de détails sur ce’Comme discuté ici, vous pouvez consulter le contenu associé plus loin dans ce guide. Si vous êtes pressé par le temps, vous pouvez également cliquer ici pour télécharger les détails de ce guide Données PDF du produit du capteur de pression d'air.

Pour plus d'informations sur d'autres technologies de capteurs, veuillez Visitez notre page de capteurs.