Cas d’application de capteurs de pression étanches dans les appareils électroniques

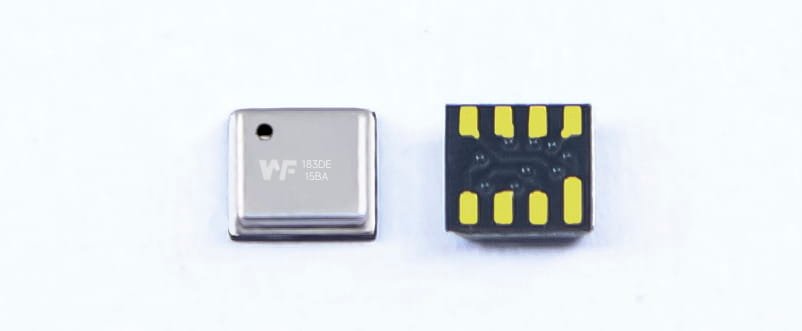

Waterproof Air pressure sensor let devices sense outside pressure without water damage. This piece covers MEMS designs, capacitive vs piezoresistive types, metal-lid/gel protection, I2C/SPI, temp compensation and production tests for watches, drones and home robots.

Cas d’application de capteurs de pression étanches dans les appareils électroniques Lire l’article »

-e1747998312687.jpg)