Natural gas explosions pose a serious threat to the safety of human property, how to effectively prevent these accidents has become a widespread industrial, commercial and domestic users of the top priority. Will explore the gas leakage detection sensors, pressure sensors, semiconductor sensors, infrared sensors, temperature sensors, etc.. in the prevention of gas explosions in the application, analyze the different types of sensors, the working principle, advantages and application scenarios, and look forward to the future development trend of sensor technology.

Tabla de contenido

1. Application of sensor technology in preventing natural gas explosions

Natural gas explosions are an extremely dangerous occurrence, usually caused by a natural gas leak. A leaking gas can explode if it mixes with air and comes into contact with an ignition source, so it is vital that leaks are detected in a timely manner. In recent years, sensor technology has played an increasingly important role in gas leak detection. Different types of sensors (p.ej. gas leak sensors, pressure sensors, semiconductor sensors, infrared sensors, temperature sensors, etc.) enable real-time monitoring of gas leaks, concentration changes and factors that may cause explosions, ensuring the safety of industrial facilities and the home environment.

2. Pressure sensors in natural gas meters

Pressure sensors play a vital role in natural gas meters. By monitoring the pressure changes in the natural gas pipeline, abnormalities in the system can be detected in time to prevent gas leakage and explosion. The following is a detailed description of the commonly used types of pressure sensors.

2.1 Analog Pressure Sensors

Analog pressure sensors are sensors that measure gas pressure through an analog signal output. The principle of operation of these sensors is usually to use pressure deformation or strain effects to sense changes in air pressure, which is converted into an analog voltage or current signal to facilitate the processing of the subsequent system. The advantages of analog pressure sensors are fast response time and high accuracy, but there are limitations in signal processing and remote monitoring.

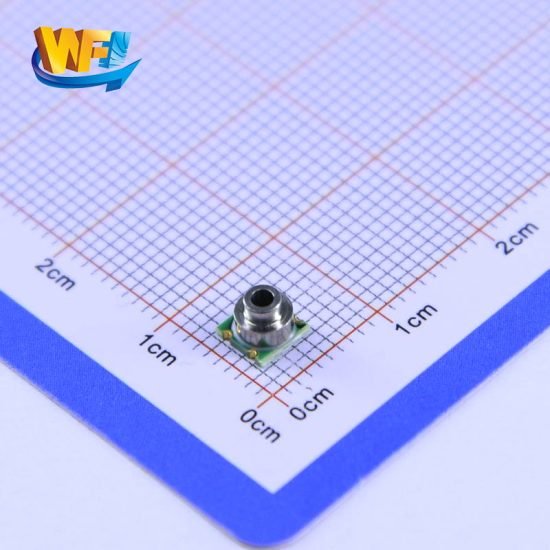

2.2 I2C Digital Pressure Sensor

I2C digital air pressure sensors are based on digital signal output and utilize the I2C communication protocol, which gives them a distinct advantage in remote data transfer and system integration. The I2C protocol allows multiple devices to share the same data bus, making it more scalable and flexible. Digital air pressure sensors are generally more accurate and immune to signal degradation and interference, making them suitable for use in complex environments.

2.3 Semiconductor Sensors

Semiconductor sensors mainly utilize the sensitivity of semiconductor materials to gases to detect flammable gases. When the natural gas and semiconductor material contact, will cause changes in the material resistance value, so as to realize the measurement of gas concentration. This type of sensor has a lower detection limit, longer service life and other characteristics, suitable for home alarms and other needs of long-term stable operation and accuracy requirements are not high occasions.

2.4 Infrared Sensors

Infrared sensors utilize the Non-Dispersive Infrared (NDIR) principle to detect hydrocarbon flammable gases in the air. Different gas molecules have different absorption characteristics in the infrared spectrum, and by measuring the degree of absorption of infrared light by the gas, the gas concentration can be measured. Infrared sensors have the advantages of good selectivity, strong anti-interference ability, not easy to be poisoned, etc.. They are especially suitable for industrial safety and gas detection, such as hydrocarbon gas detection.

2.5 temperature sensors

Temperature sensors are key devices that monitor changes in ambient temperature and play an important role in the prevention of natural gas explosions. Gas leaks or pipeline breaks can lead to gas buildup, which can ignite or even explode when exposed to a heat source or high ambient temperatures. By monitoring temperature changes in real time, temperature sensors can help detect hazards such as gas leaks, ignition sources or system overheating so that timely safety measures can be taken.

3. How the Air Pressure Sensor Works

3.1 How Sensors Work

Pneumatic sensors usually work by utilizing the principles of piezoelectric effect, resistance effect or capacitance change effect. When a gas leak or pressure change occurs, the sensitive components in the sensor undergo physical changes that are converted into electrical signals. These signals can then be collected and transmitted to the monitoring system for further analysis and alarms.

3.2 Pneumatic Pressure Measurement

The principle of pneumatic pressure measurement relies primarily on measuring the pressure exerted by gas molecules on an object. Different sensors use different physical effects to achieve this measurement: Por ejemplo, resistive strain sensors determine pressure by measuring changes in the resistance of metal or semiconductor materials, and capacitive sensors sense pressure through changes in capacitance caused by changes in air pressure.

4. What is the preventive function of pressure sensors?

The pressure sensor can detect abnormal pressure fluctuations in real time by monitoring the pressure changes in the natural gas pipeline in real time. If there is a sudden drop in pressure, it may indicate a leak in the pipeline, and the sensor will immediately send out an alarm, prompting the relevant personnel to take emergency measures. Además, the pressure sensor can also monitor the gas flow to ensure that the natural gas equipment is operated within a safe working pressure range, to prevent over-pressure or low-pressure failure.

5. How pressure sensors work using the ideal gas law

The operating principle of pressure sensors is closely related to the Ideal Gas Law. The ideal gas law states that the pressure of a gas is directly proportional to its temperature and volume. By utilizing this principle, the sensor can deduce the state of the gas based on the pressure change of the gas and monitor the stability of the system through the pressure sensor. Ideal gas law provides a theoretical basis for gas pressure sensors, so that it plays an important role in natural gas explosion prevention.

6. How to choose which gas pressure sensor to use the best

Choosing the right gas pressure sensor needs to take into account a number of factors, such as measurement range, accuracy, response time, environmental adaptability. Analog barometric sensors are suitable for applications requiring high response time and accuracy, while I2C digital barometric sensors offer significant advantages for system integration and remote monitoring. When choosing a gas pressure sensor, it is important to weigh the specific needs of the application to ensure that the sensor is maximized for preventing natural gas explosions.

7. Strengths and Challenges of Sensor Technology

7.1 Advantages

- Real-time monitoring: Sensors enable real-time monitoring of natural gas concentration, pressure, temperature and other parameters, ensuring that measures can be taken quickly in the event of a leak or anomaly.

- High sensitivity: modern sensor technology has a very high sensitivity, can accurately detect trace gas leakage, to provide sufficient time for explosion prevention.

- Automatización: Sensor systems can be connected to alarm systems, gas cut-off devices and other equipment, automated response to improve safety.

7.2 Challenges

- Environmental impact: Sensor accuracy can be affected by ambient temperature, humidity, airflow and other factors, especially in complex industrial environments, requiring the selection of a suitable sensor model.

- Cost: Highly accurate and sensitive sensors are more expensive, which may make them less popular with some small businesses or home users.

- Failure rate: Sensors may age and fail with long-term use. Maintaining the stability and reliability of sensors remains a challenge in the development of technology.

8. Trends in Sensor Technology

As technology continues to advance, so does the performance of sensors. En el futuro, sensors will develop in the following directions:

- Higher accuracy and sensitivity: The use of new materials and more advanced manufacturing processes will further enhance the performance of sensors, enabling the detection of even smaller gas leaks.

- Wireless transmission: The advent of wireless sensor networks will greatly enhance the convenience and immediacy of data transmission, especially for remote monitoring and data analysis.

- Integration and Intelligence: Intelligent sensors that integrate multiple sensing functions will become the trend of the future, able to simultaneously monitor gas concentration, temperatura, pressure and other parameters to achieve more comprehensive explosion prevention.

Conclusión

Natural gas explosions are a major safety hazard and sensor technology plays a vital role in preventing them. Through real time monitoring of gas concentration, pressure, temperature changes and other key parameters, the sensor can take emergency measures to ensure safety before the danger occurs. With the continuous development of sensor technology, more precise and efficient safety protection will be realized in the future in terms of gas leakage detection, pressure monitoring, sampling rate, sensibilidad, resolution and accuracy. For the natural gas industry, industrial production and home users to play a more important role in protecting peoples lives and property safety.