Los sensores de presión cerámica se han vuelto esenciales en muchas aplicaciones industriales y cotidianas. Si está trabajando en el campo de la medicina, industria automotriz, o incluso aeroespacial, Estos sensores proporcionan confiables, Mediciones precisas incluso en entornos extremos. Su composición de cerámica única, junto con varias mejoras tecnológicas, les da una ventaja sobre muchos otros tipos de sensores.

Catalogar

Ventajas y aplicaciones de sensores de presión cerámica en la industria moderna

Los sensores de presión cerámica han surgido como componentes críticos en diversas industrias debido a su excepcional durabilidad, precisión, y adaptabilidad. Estos sensores aprovechan las propiedades únicas de la cerámica avanzada, como la alúmina y la circonía, para ofrecer un rendimiento confiable en entornos donde falsifican los sensores tradicionales a base de metal. De aplicaciones aeroespaciales a biomédicas, Los sensores de presión cerámica ofrecen ventajas como la estabilidad de alta temperatura, resistencia química, y retención de calibración a largo plazo. Este informe explora los principios de trabajo, innovaciones tecnológicas, e implementaciones prácticas de sensores de cerámica, Proporcionar información procesable para ingenieros y especialistas en adquisiciones. Analizando avances recientes en diseños de sensores de cerámica capacitivos y piezoresistivos, Este artículo equipa a los lectores con el conocimiento para optimizar la selección de sensores para condiciones operativas duras mientras mantiene la precisión de la medición.

Principios fundamentales de la operación del sensor de presión cerámica

Mecanismos de detección piezoeléctricos y capacitivos

Los sensores de presión cerámica funcionan principalmente a través de dos mecanismos: el efecto piezoeléctrico y detección capacitiva. En cerámica piezoeléctrica como el titanato de circonato de plomo (PZT), La presión aplicada induce la deformación de la red de cristal, generando una carga eléctrica proporcional1. Esta carga se acumula en superficies de electrodos y se convierte en señales de voltaje medibles a través de amplificadores de carga integrados. Diseños capacitivos, como los que usan sustratos de alúmina, medir los cambios en la brecha entre un diafragma cerámico deformado y un electrodo fijo, con variaciones de capacitancia que reflejan diferenciales de presión.

El enfoque piezoeléctrico sobresale en escenarios de medición de presión dinámica, como el monitoreo de la cámara de combustión, donde las fluctuaciones de presión rápida requieren una respuesta de alta frecuencia. Diseños capacitivos, en cambio, Proporcionar una estabilidad superior para las mediciones de presión estática en aplicaciones como los sistemas hidráulicos. Los sensores de cerámica a base de MEMS modernos combinan ambos principios, Incrustación de medidores de tensión piezoresistiva en diafragmas de cerámica de película delgada para lograr una precisión a gran escala de ± 0.1%

Ventajas materiales de sustratos de cerámica

Estabilidad térmica y química

Alúmina (Al₂O₃) La cerámica dominan la fabricación del sensor de presión debido a sus excepcionales propiedades térmicas. Con un coeficiente de expansión térmica (Cte) de 7.2 × 10⁻⁶/° C (20-1000° C Rango), Los sustratos de alúmina mantienen la estabilidad dimensional en los rangos de temperatura industrial (-40° C a 300 ° C). Esto minimiza la deriva de medición inducida por la temperatura en comparación con el acero inoxidable (Cte: 17.3 × 10⁻⁶/° C).

La resistencia química surge de la cerámica’ estructura covalente de unión atómica. Los sensores de alúmina resisten la exposición prolongada a:

ph 0-14 soluciones (excluyendo el ácido hidrofluórico)

Hidrocarburos clorados a 150 ° C

Corrientes de gas que contienen azufre hasta 400 ° C

Esta durabilidad permite el despliegue en galletas catalíticas de refinería de petróleo y vasos de reactores farmacéuticos donde los sensores metálicos corroerían rápidamente.

Métricas de rendimiento de precisión

Calibración y estabilidad a largo plazo

Los sensores de presión cerámica de alto grado logran ± 0.25% FS (escala completa) Precisión a través de resistencias de película gruesa cortada por láser y ASIC de acondicionamiento de señal avanzado. El modelo WINSEN WPAH01 demuestra 0.1% no linealidad en su 0-30 Barra de alcance, Mantener la estabilidad de la calibración dentro de ± 0.05% FS/año bajo una operación continua de 150 ° C

Factores clave que influyen en la precisión:

Espesor del diafragma: 0.2Los diafragmas de alúmina MM proporcionan una sensibilidad de desviación óptima mientras se resisten a la fractura (presión de ráfaga >10× capacidad nominal)

Técnicas de carpinero: La unión de frit de vidrio crea sellos herméticos con tasas de fuga <1× 10⁻⁹ mbar · l/s, Prevención de la entrada de medios

Compensación de temperatura: PT1000 RTDS en chip habilita la corrección de errores térmicos en tiempo real

Estudios de casos de aplicación industrial

Monitoreo aguas arriba de petróleo y gas

En instalaciones de árbol de Navidad submarino, Sensores capacitivos de cerámica wika (Modelo C-10) medir de manera confiable las presiones de la cabeza de pozo hasta 15,000 PSI a 175 ° C temperaturas de agua de mar. Los elementos de detección de alúmina resisten el fragilización de sulfuro de hidrógeno y la erosión de la arena, logrando MTBF >250,000 Horas en despliegues de BP del Mar del Norte

Optimización del turbocompresor automotriz

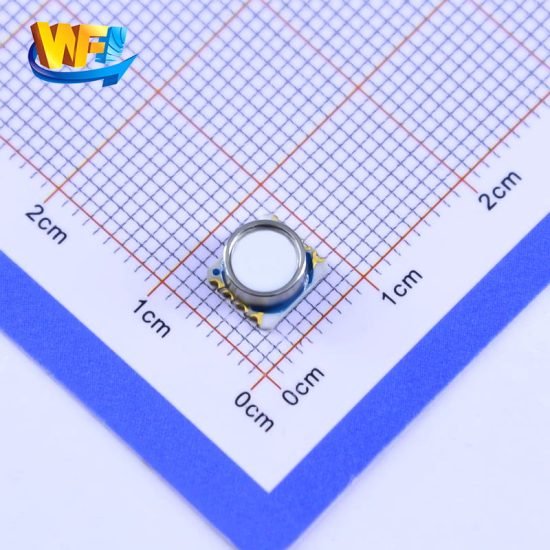

Sensores de cerámica piezoresistiva a base de MEMS (P.EJ., WF5803C) Monitorear la presión de impulso turbo con tiempos de respuesta de 2 ms. Los diafragmas de circonio estabilizados con Yttria resisten las temperaturas de los gases de escape de 220 ° C mientras se mantiene la precisión de ± 1kPa 0-30 rangos de barra.

Criterios de selección para un rendimiento óptimo

Matriz de compatibilidad ambiental

| Parámetro | Idoneidad del sensor de cerámica | Comparación del sensor metálico |

|---|---|---|

| Rango de temperatura | -40° C a +400 ° C | -20° C a +150 ° C |

| Resistencia química | Excelente (ph 0-14) | Pobre (Requiere recubrimientos) |

| Conmoción/vibración | 1000g de supervivencia máxima | 500G pico |

| Compatibilidad con los medios | Todos los líquidos/gases no HF | Limitado por material de diafragma |

Fuentes de datos:

Para aplicaciones de alta precisión, especificar sensores con:

Certificados de calibración para trazables por NIST

Compensación de temperatura integrada

Diseños aislados de medios para fluidos corrosivos

Protocolos de mantenimiento y calibración

Procedimiento de calibración de campo

Ajuste de punto cero: Aplicar referencia al vacío y ajustar el desplazamiento a través de Hart Communicator

Calibración del tramo: Use el probador de peso muerto para aplicar 90% Presión fs

Linealización: Programa de la curva de corrección de 5 puntos en la EEPROM del sensor

Control de histéresis: Presión del ciclo de 0 → 100%→ 0 → 100%→ 0, verificación <0.05% desviación

El mantenimiento adecuado extiende los intervalos de servicio a 5+ Años en aplicaciones que no son de sobornos. Limpieza ultrasónica (40khz, 30W/l) Elimina efectivamente la acumulación de partículas sin dañar las superficies cerámicas

Desarrollos tecnológicos emergentes

Redes de sensores de MEMS inalámbricos

Prototipos recientes de Honeywell Combine los transceptores Zigbee de 2.4GHz con sensores de cerámica piezoeléctricos autopotencias. La recolección de energía de las fluctuaciones de presión (≥0.2Hz) habilita la operación sin batería en las cuadrículas de monitoreo de la tubería.

Carburo de silicio sinterizado a alta temperatura

Los sensores de cerámica SIC ahora funcionan continuamente a 600 ° C en las turbinas de gas H de GE. La conductividad térmica de 4.5W/m · k del material evita la deriva de la señal inducida por calor durante los cambios rápidos de carga.

Conclusión

Los sensores de presión cerámica resuelven desafíos de medición crítica en todas las industrias a través de su combinación única de propiedades del material y procesamiento de señal avanzado. Al comprender la interacción entre la composición de cerámica, metodología de detección, y entorno de aplicación, Los ingenieros pueden especificar sensores que superan a las tecnologías tradicionales mientras mantienen la precisión. Los desarrollos continuos en conectividad inalámbrica y materiales de ultra alta temperatura prometen expandir su aplicabilidad a los sistemas energéticos de próxima generación e infraestructura industrial de IoT.

La introducción anterior solo rasca la superficie de las aplicaciones de la tecnología del sensor de presión. Continuaremos explorando los diferentes tipos de elementos de sensores utilizados en varios productos., Cómo funcionan, y sus ventajas y desventajas. Si desea más detalles sobre lo que se discute aquí, Puede consultar el contenido relacionado más adelante en esta guía. Si está presionado por el tiempo, También puede hacer clic aquí para descargar los detalles de estas guías Producto del sensor de presión de aire datos PDF.

Para obtener más información sobre otras tecnologías de sensores, por favor Visite nuestra página de sensores.