Las bombas de vacío modernas ya no se limitan simplemente a generar succión: están evolucionando hacia un control inteligente y preciso. Al integrar sensores de presión de alta precisión, los sistemas de bombas de vacío pueden monitorear la presión negativa en tiempo real y ajustar dinámicamente la salida, asegurando un funcionamiento estable y una medición precisa al tiempo que minimiza los riesgos del equipo. Este artículo profundiza en cómo los sensores de presión de las bombas de vacío, como los del Serie WF100E, aprovecha la tecnología avanzada para lograr una medición de presión negativa de alta precisión, revolucionando las aplicaciones en entornos industriales, médicos y de IoT.

Catalogar

Cómo funciona el sensor de presión

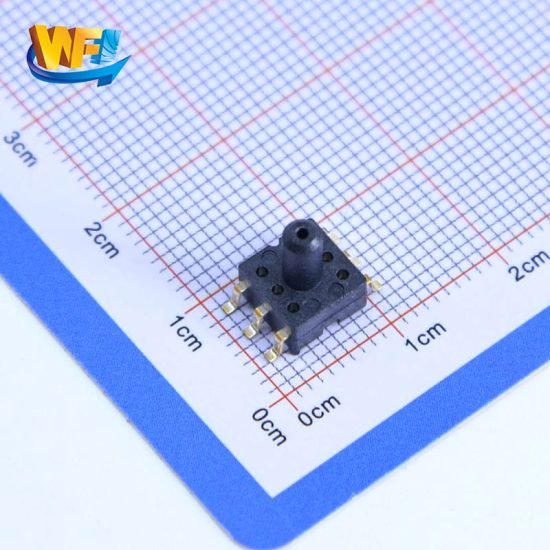

El núcleo de una bomba de vacío es su capacidad para generar y mantener una presión negativa estable, una tarea que exige una medición precisa de la presión. Los sensores de la serie WF100E emplean tecnología MEMS de vanguardia junto con el procesamiento de señales mixtas CMOS para garantizar que cada medición cumpla con estándares de alta precisión. Los aspectos clave de su operación incluyen:

Monitoreo de presión en tiempo real

El sensor convierte la presión física en una señal de voltaje eléctrico, con un rango de salida estándar de 0,2 a 4,7 V. Usando la fórmula

Calcula con precisión la presión negativa.

Compensación de temperatura y estabilidad a largo plazo

Al operar en un amplio rango de temperaturas de -40 °C a 125 °C, el sensor mantiene una alta linealidad (≤0,5 % de error FS) y una baja deriva del cero (±0,03 FS/°C), lo que garantiza un rendimiento confiable en condiciones ambientales variables.

Acondicionamiento de señal y transmisión de datos

Un ASIC de acondicionamiento de señal integrado amplifica y corrige la señal sin procesar, transmitiendo los datos a través de interfaces estándar (como I2C o SPI) al sistema de control para la regulación dinámica de la presión negativa.

La importancia del control de presión negativo inteligente

En muchas aplicaciones, la medición de presión negativa afecta no sólo a la eficiencia de un sistema sino también a su seguridad y comodidad del usuario:

Control de precisión

Con retroalimentación de datos en tiempo real, la bomba de vacío puede ajustar automáticamente la succión para mantener la presión negativa dentro de un rango óptimo, evitando problemas causados por una succión excesiva o insuficiente.

Eficiencia del sistema mejorada

El ajuste dinámico de la succión genera operaciones con mayor capacidad de respuesta, ciclos de trabajo más cortos, menor consumo de energía y una vida útil más larga del equipo.

Gestión de datos inteligente

Cuando se combinan con la tecnología IoT, los sensores pueden transmitir datos en tiempo real a plataformas en la nube, lo que permite a los usuarios o técnicos analizar y optimizar los parámetros operativos para una fabricación más inteligente y un monitoreo remoto.

El papel de los sensores de presión en los sistemas de bombas de vacío

Los sensores de presión desempeñan un papel fundamental en los sistemas de bombas de vacío, con beneficios clave que incluyen:

Monitoreo en tiempo real de cambios de presión negativa

Medir con precisión cada fluctuación de presión proporciona una base de datos confiable para el sistema.

Ajuste de succión automática

Basado en datos en tiempo real, el sistema puede modular rápidamente la succión para mantener la presión negativa dentro de un rango preestablecido, mejorando la estabilidad general.

Registro de datos y administración remota

Con las plataformas de visualización, los usuarios pueden realizar un seguimiento de los datos históricos, analizar el rendimiento del sistema y abordar posibles problemas de forma proactiva.

Ingeniería y mantenimiento optimizados

La alta integración reduce la complejidad del circuito, simplificando el diseño del sistema y agilizando los esfuerzos de mantenimiento.

Parámetros operativos detallados de los sensores de vacío (suplementarios)

Además de la función general del sistema, los sensores de vacío también deben cumplir una serie de estrictos requisitos de ingeniería para garantizar que las bombas de vacío funcionen de manera confiable y eficiente en diversas condiciones. En concreto, los sensores están diseñados con las siguientes características:

Rango de medición de presión:

Típicamente diseñado para funcionar dentro de una gama de -100 kPa a 0 kPa, asegurando cobertura para la mayoría de aplicaciones de bombas de vacío.

Exactitud:

El sensor mantiene un error a gran escala dentro ± 1% span, junto con una deriva cero baja (± 0.03 FS/℃) para ofrecer mediciones de alta precisión a largo plazo.

Resolución:

Al aprovechar el rango de salida estándar de 0,2 a 4,7 V y la fórmula de conversión, cada cambio de voltaje incremental corresponde a variaciones sutiles de presión, lo que permite que el sensor detecte de manera efectiva incluso fluctuaciones menores (0Resolución de 0,001 kPa).

Tasa de respuesta:

Utilizando tecnología MEMS avanzada y acondicionamiento de señal integrado, el sensor ofrece una rápida 1ms capacidades de respuesta para capturar cambios de presión en tiempo real, cumpliendo con los requisitos de carga dinámica y permitiendo ajustes rápidos de succión.

Compensación de temperatura de funcionamiento:

Con un rango operativo robusto de -40 °C a 125 °C, el mecanismo de compensación de temperatura incorporado del sensor minimiza el impacto de las fluctuaciones de temperatura en la precisión de la medición, lo que garantiza una alta linealidad y precisión en diversos entornos.

Conclusión

La integración de sensores de presión en sistemas de bombas de vacío está impulsando un cambio del control de succión convencional a una gestión inteligente y precisa. Representados por la serie WF100E, los sensores de alta precisión destacan en medición en tiempo real, ajuste automático y compensación de temperatura, y ofrecen soluciones seguras, eficientes e inteligentes en diversas industrias. A medida que avanza la tecnología, podemos esperar que estos sistemas inteligentes desempeñen un papel aún mayor en la automatización industrial, la atención médica y las aplicaciones de IoT, estableciendo nuevos puntos de referencia para la innovación y la confiabilidad.

La introducción anterior sólo toca la superficie de las aplicaciones de la tecnología de sensores de presión. Continuaremos explorando los diferentes tipos de elementos sensores utilizados en diversos productos, cómo funcionan y sus ventajas y desventajas. Si desea obtener más detalles sobre lo que se analiza aquí, puede consultar el contenido relacionado más adelante en esta guía. Si tiene poco tiempo, también puede hacer clic aquí para descargar los detalles de estas guías. Producto del sensor de presión de aire datos PDF.

Para obtener más información sobre otras tecnologías de sensores, por favor Visite nuestra página de sensores.