Catalogar

Los sensores de presión desempeñan un papel fundamental en el diseño industrial y de productos moderno, proporcionando mediciones precisas en diversas aplicaciones. Los clientes deben equilibrar el rendimiento técnico con las restricciones presupuestarias. El siguiente artículo, basado en datos y experiencias de usuarios genuinos, examina los factores que influyen en los precios, describe los rangos de precios para diferentes tipos de sensores, ofrece consejos prácticos de compra y destaca campos de aplicación clave, todo con el objetivo de ayudarle a elegir el sensor de presión más adecuado para sus necesidades.

Consideraciones para la selección de precios

1. El tipo de sensor afecta el precio

Los diferentes sensores de presión (como los de aire, manométricos, absolutos y diferenciales) se producen utilizando diversos procesos de diseño y fabricación que impactan directamente en su costo. Definir claramente sus necesidades de medición ayuda a evitar gastar demasiado en funciones que no necesita.

2. La marca y la calidad determinan el precio

Las marcas de renombre se adhieren a estrictos controles de calidad, lo que garantiza una mayor estabilidad y precisión. Aunque estos sensores pueden tener un precio más alto, ofrecen un rendimiento confiable. Equilibrar la prima de marca con sus requisitos de uso reales es esencial para una rentabilidad óptima.

3. Requisitos de alcance y precisión

El rango de medición y la precisión de un sensor son importantes factores de coste. Los sensores con mayor precisión y rangos más amplios requieren una fabricación y calibración más avanzadas, lo que aumenta su precio. Hacer coincidir estas especificaciones con sus necesidades reales es clave para evitar gastos innecesarios.

4. Rango de presión de funcionamiento

La presión de trabajo esperada influye significativamente en el diseño del sensor. En entornos de alta presión, los sensores necesitan características de seguridad adicionales y materiales reforzados, lo que aumenta el costo. Es fundamental elegir un sensor que cumpla con las demandas operativas de su aplicación.

5. Factores materiales y ambientales

La elección de los materiales afecta la durabilidad de un sensor y su capacidad para soportar condiciones adversas. Los sensores construidos con materiales que resisten altas temperaturas, corrosión o atmósferas explosivas suelen costar más, pero garantizan confiabilidad a largo plazo en entornos exigentes.

6. Tipo de señal de salida

Los sensores de presión vienen con salidas digitales o analógicas. Los sensores digitales simplifican el procesamiento de datos y la integración del sistema, pero normalmente tienen un precio elevado. Los sensores analógicos, por otro lado, ofrecen precios más flexibles y al mismo tiempo cumplen con los requisitos básicos de rendimiento. Considere la compatibilidad de su sistema al tomar una decisión.

7. Costo adicional por funciones especiales

Algunos sensores ofrecen funciones adicionales como transmisión inalámbrica, calibración automática o detección multiparámetro. Estos extras tienden a aumentar el costo general, así que evalúe si estas características brindan beneficios reales para su aplicación antes de incurrir en gastos adicionales.

Rangos de precios para diferentes tipos de sensores

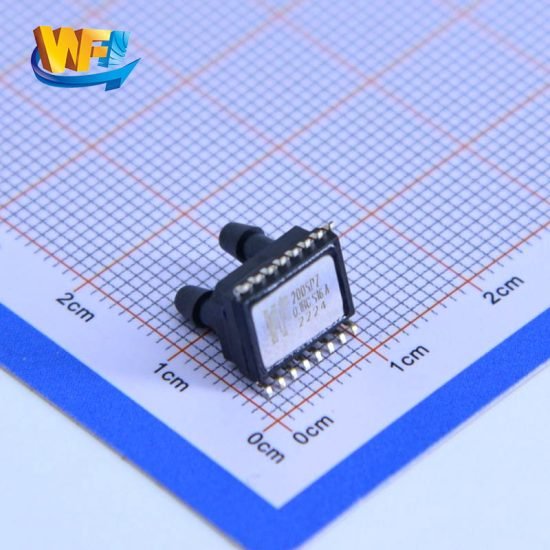

1. Rango de precios del sensor de presión de aire

Los sensores de presión de aire, que normalmente se utilizan en estaciones meteorológicas y de monitoreo ambiental, están disponibles a precios asequibles. Dependiendo del rango de presión, los modelos de gama baja pueden costar entre $0,1 y $10 aproximadamente, mientras que los modelos avanzados con funciones adicionales pueden costar entre $20 y $50.

2. Rango de precios del sensor de presión manométrica

Los sensores de presión manométrica se utilizan ampliamente en aplicaciones industriales y automotrices. Las variaciones de precios dependen de las especificaciones técnicas y la reputación de la marca. Generalmente, los modelos básicos oscilan entre $1 y $20, las opciones de rango medio entre $20 y $100 y los modelos premium pueden costar entre $100 y $200 o más.

3. Rango de precios del sensor de presión absoluta

Los sensores de presión absoluta, diseñados para sistemas sellados o de vacío, requieren mayor sellado y precisión. Normalmente, los productos básicos cuestan entre 5 y 50 dólares, los modelos de gama media entre 50 y 150 dólares y los sensores de alta especificación pueden costar entre 150 y 300 dólares.

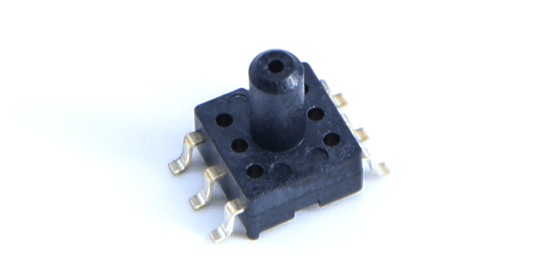

4. Precio del sensor de presión diferencial

Los sensores de presión diferencial, utilizados para medir diferencias de presión entre dos puntos, varían según el rango de medición y la precisión. Los modelos básicos pueden comenzar entre $1 y $30, las opciones de rango medio entre $30 y $150, y los modelos de gama alta pueden tener un precio entre $150 y aproximadamente $250.

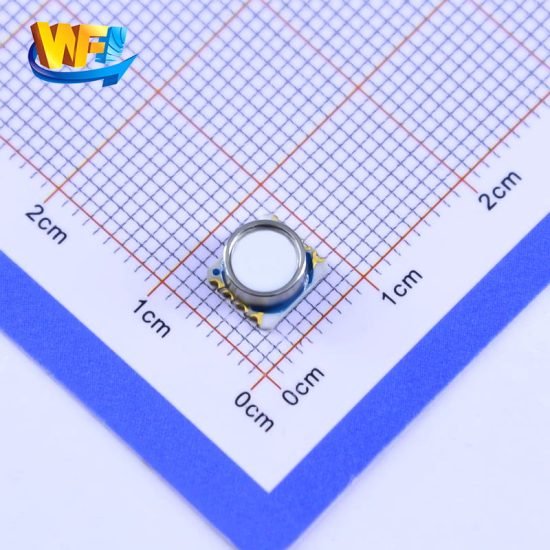

5. Rango de precios del sensor de presión digital

Los sensores de presión digitales destacan en la adquisición de datos y el monitoreo en tiempo real. Su precio es generalmente más alto que el de los sensores analógicos: los modelos básicos pueden tener un precio de 0,1 a 5 dólares, las unidades de rango medio de 5 a 20 dólares y los sensores de gama alta pueden costar entre 20 y 50 dólares o más.

6. Características del precio del sensor de presión amplificado (analógico)

Los sensores amplificados o analógicos se benefician de procesos de producción maduros, lo que conduce a precios flexibles. Los modelos básicos se pueden encontrar por tan solo 0,1 a 10 dólares, los productos de gama media suelen oscilar entre 10 y 50 dólares, y los modelos de gama alta pueden costar entre 50 y 100 dólares.

7. Características del precio del sensor de presión cerámico

Los sensores de presión cerámicos son conocidos por su resistencia a las altas temperaturas y a la corrosión, lo que los hace ideales para entornos hostiles. Los modelos básicos pueden costar entre 50 y 100 dólares, las opciones de gama media entre 100 y 300 dólares, y los sensores premium pueden oscilar entre 300 y 500 dólares.

8. Tendencia del precio del sensor de presión de neumáticos

Los sensores de presión de neumáticos, cruciales para el control de la seguridad del automóvil, varían según el rango de presión y las características técnicas. Generalmente, los precios oscilan entre 0,1 y 5 dólares para los modelos estándar, mientras que los sensores avanzados con múltiples funciones pueden costar entre 10 y 35 dólares.

9. Tendencia del precio del sensor de presión de vacío

Los sensores de presión de vacío, utilizados en instrumentos científicos y sistemas de vacío, tienen precios más altos debido a su diseño especializado y precisión. Los modelos básicos suelen costar entre 1 y 15 dólares, los productos de gama media suelen costar entre 10 y 30 dólares y los sensores de alta precisión pueden superar los 30 a 50 dólares.

Consejos y sugerencias de compra

1. ¿Cómo elegir según sus necesidades?

Comience por definir claramente los requisitos clave de su aplicación, como precisión, alcance y condiciones ambientales. Distinga entre funciones esenciales y opcionales para asegurarse de seleccionar un sensor que satisfaga sus necesidades sin extras innecesarios.

2. ¿Dónde encontrar productos rentables?

Los distribuidores acreditados y las plataformas especializadas son su mejor opción para obtener sensores de alta calidad con un sólido soporte posventa. Las reseñas de clientes y los estudios de casos también pueden ayudar a identificar los productos que ofrecen la mejor relación calidad-precio.

3. Parámetros clave a considerar al comprar

Concéntrese en las especificaciones técnicas críticas, como la precisión, el tiempo de respuesta, la durabilidad y el rango de presión y temperatura de funcionamiento del sensor. Además, revise las certificaciones y los informes de inspección para garantizar que el sensor cumpla con los estándares de la industria.

4. ¿Cómo evaluar la calidad del producto?

Evalúe la calidad del producto considerando las credenciales del fabricante, los comentarios de los usuarios y los informes de pruebas de terceros. Las evaluaciones in situ y los períodos de prueba también pueden proporcionar confirmación de primera mano del rendimiento de un sensor.

5. Factores a considerar para el servicio posventa

Un soporte postventa confiable es crucial. Busque fabricantes que ofrezcan asistencia técnica inmediata, términos de garantía razonables, tiempos de respuesta de reparación rápidos y repuestos fácilmente disponibles. Revisar estas políticas de servicio antes de la compra puede evitar problemas futuros.

6. Modelos y marcas comunes

Numerosas marcas conocidas ofrecen una variedad de modelos de sensores de presión. Centrarse en aquellos con una sólida reputación en su industria puede ayudarlo a garantizar que invierta en un producto que satisfaga sus necesidades técnicas y operativas.

Aplicaciones y campos relacionados

1. Aplicaciones en Automatización Industrial

En las líneas de producción automatizadas, los sensores de presión son esenciales para monitorear el estado de los equipos en tiempo real, garantizando operaciones fluidas y evitando costosos tiempos de inactividad debido a fallas de los equipos.

2. Uso en la industria automotriz

Los sensores de presión son parte integral de la gestión del motor, los sistemas de frenos y el control de la presión de los neumáticos en los vehículos, y contribuyen significativamente a la seguridad y el rendimiento generales.

3. Monitoreo de presión en dispositivos médicos

Los dispositivos médicos, como los ventiladores y los monitores de presión arterial, dependen de sensores de presión precisos para proporcionar datos precisos, lo cual es fundamental para la atención al paciente y la eficacia del tratamiento.

4. Detección de presión en el monitoreo ambiental

En las estaciones meteorológicas y los sistemas de monitoreo ambiental, los sensores de presión recopilan datos esenciales, como la presión atmosférica y la velocidad del viento, que respaldan la investigación climática y los sistemas de alerta temprana.

5. Medición de presión en electrónica de consumo

Desde relojes inteligentes hasta dispositivos de monitoreo del hogar, los sensores de presión se incorporan cada vez más a la electrónica de consumo, proporcionando datos en tiempo real que mejoran la vida cotidiana con tecnología más inteligente.

Conclusión

Seleccionar el sensor de presión adecuado implica un cuidadoso equilibrio entre las especificaciones técnicas, el costo y el rendimiento práctico. Al comprender los factores clave y considerar las experiencias de los usuarios del mundo real, puede elegir un sensor que no solo satisfaga sus demandas operativas sino que también ofrezca un valor excelente y confiabilidad a largo plazo. La información proporcionada aquí tiene como objetivo guiarlo para tomar una decisión bien informada que se alinee tanto con sus requisitos técnicos como con sus limitaciones presupuestarias.

La introducción anterior sólo toca la superficie de las aplicaciones de la tecnología de sensores de presión. Continuaremos explorando los diferentes tipos de elementos sensores utilizados en diversos productos, cómo funcionan y sus ventajas y desventajas. Si desea obtener más detalles sobre lo que se analiza aquí, puede consultar el contenido relacionado más adelante en esta guía. Si tiene poco tiempo, también puede hacer clic aquí para descargar los detalles de estas guías. Producto del sensor de presión de aire datos PDF.

Para obtener más información sobre otras tecnologías de sensores, por favor Visite nuestra página de sensores.