Catalogar

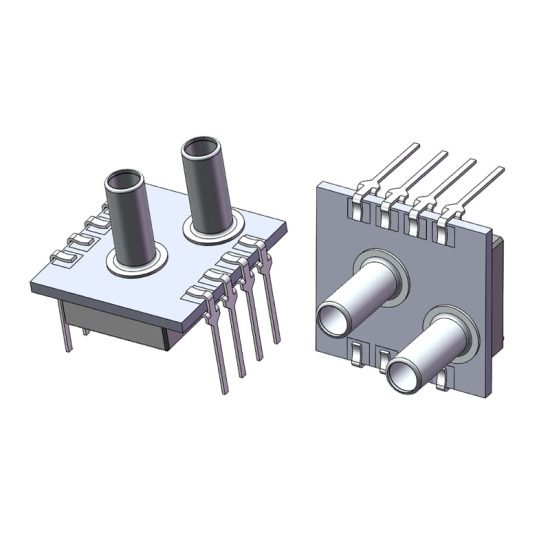

The WF1525 series is a low-pressure differential MEMS sensor with ranges of 5kPa, 7kPa, and 10kPa. The device uses a 3D diaphragm structure and constant-current drive (recommended 1.5mA), and implements full on-chip temperature compensation from −10°C to 60°C. Laser trimming locks the static zero and compensated zero points. With an external resistor and differential amplifier, precise span calibration is achievable. The package is a DIP short-tube type, suitable for medical devices, ventilators, HVAC, and more. The attached image shows a dual-port short-tube DIP appearance consistent with WF1525 packaging.

1 Design and Range Matching

WF1525 uses a three-dimensional diaphragm structure to improve sensitivity and linearity and is specially designed for three small full-scale ranges: 5kPa, 7kPa, and 10kPa. The device is differential type, with a typical measurement range of −5kPa to +5kPa. During design, mechanical stress, package stress, and thermal expansion effects are optimized by process and structural controls to reduce nonlinearity and zero drift, ensuring stable output within the rated range and facilitating direct replacement or integration into existing measurement channels.

2 Temperature Compensation Mechanism

WF1525’s chip-level temperature compensation covers −10°C to 60°C. It combines factory calibration with an internal compensation network to reduce temperature-induced sensitivity and zero drift. Compensation parameters are written into calibration tables or implemented via built-in resistor networks. When used with an external differential amplifier, it achieves optimal linearity and error control within the specified temperature band, providing usable and calibratable signals under complex ambient temperature changes.

3 Laser Trimming and Zero Calibration

During production, laser trimming is used for static zero and compensated zero calibration, precisely adjusting resistances or microstructures to correct zero offsets. Laser trimming enables fine, repeatable corrections and is more stable than traditional trimming methods. Combined with the constant-current drive calibration workflow at shipping, this ensures zero and span are locked within target accuracy, improving production consistency and long-term stability.

4 Constant-Current Drive and External Span Calibration

WF1525 recommends a constant-current drive of 1.5mA. Constant-current driving stabilizes the sensor output and reduces errors from supply variations. Because of the constant-current drive architecture, the product requires a parallel resistor and an external differential amplifier. At the system level, span calibration is achieved by adjusting the external resistor and amplifier gain, meeting diverse signal-processing and interface needs while maintaining zero stability and high linearity.

5 Packaging, Ports, and Reliability

All WF1525 variants use a dual in-line (DIP) package with short-tube ports for easy mounting and strong interface compatibility. The device’s rated operating temperature is −40°C to +85°C, while optimal accuracy and linearity are achieved within the −10°C to 60°C compensation range. The package design balances thermal paths and stress isolation to minimize external stress on the diaphragm. Production testing includes drift and static zero verification to ensure industrial-grade reliability and consistency.

Conclusión

WF1525 integrates 3D-diaphragm sensitivity, chip-level temperature compensation, laser trimming, and constant-current drive into a combined solution for repeatable, calibratable low-pressure measurement. Through precise factory compensation and system-level external calibration, the device maintains zero stability and measurement accuracy in practical applications, suitable for medical equipment, ventilators, HVAC, flow and liquid-level measurement, and other scenarios with strict requirements for temperature robustness and zero-point consistency.

La introducción anterior sólo toca la superficie de las aplicaciones de la tecnología de sensores de presión. Continuaremos explorando los diferentes tipos de elementos sensores utilizados en diversos productos, cómo funcionan y sus ventajas y desventajas. Si desea obtener más detalles sobre lo que se analiza aquí, puede consultar el contenido relacionado más adelante en esta guía. Si tiene poco tiempo, también puede hacer clic aquí para descargar los detalles de estas guías. Producto del sensor de presión de aire datos PDF.

Para obtener más información sobre otras tecnologías de sensores, por favor Visite nuestra página de sensores.