Catalogar

Smartwatch blood pressure monitoring relies on precise coordination between a micro pump and a high-resolution pressure sensor. Centered on the WF3050D digital MEMS sensor, this article delivers an end-to-end solution: from requirements analysis, sensor selection, system integration, to installation/soldering best practices and pre-production testing tools. The approach balances ultra-compact size, low power, and high accuracy, enabling rapid feasibility assessment and deployment.

Solo como referencia

Análisis de antecedentes y requisitos de la aplicación

A smartwatch blood pressure feature must control pressure changes within a tiny space. The micro pump should fit under 1cm³ and generate 0–50kPa; the sensor requires ±1%FS accuracy, digital output, and low drift (≤0.5%FS/°C), with standby current <10µA and active <1mA. Motion and temperature variation on the wrist pose stability challenges, demanding ≥200Hz sampling for clear pulse waveform capture. Engineers must balance layout, power design, and algorithm integration, while procurement managers focus on supply consistency and production yield.

1.1 Space and Power Constraints

Ultra-compact module combines pump, tubing, and sensor, with attention to heat dissipation and shock resilience.

Low overall power draw extends battery life, matching watch capacity.

1.2 Accuracy and Responsiveness

±1%FS meets medical monitoring standards.

≥200Hz sampling captures full pulse waveform without aliasing.

1.3 Interface Compatibility

WF3050D’s PDM/I²S digital interface reduces PCB complexity.

Fast bus integration with MCU simplifies firmware design.

Selección del sensor y coincidencia de parámetros

Among MEMS sensors, the WF3050D stands out: 3.0×5.0×0.93mm size, 0–50kPa range, digital I²S/PDM, and 0.48%FS/°C drift. Typical accuracy ≤±0.5%FS supports blood pressure tracking up to 200mmHg. Operating voltage 1.7–3.6V matches watch rails, and no external ADC is needed. Top-port design eases gas routing; metal lid adds impact resistance.

2.1 Range and Precision

0–50kPa covers 95–200mmHg clinical window.

Non-linearity ≤±0.3%FS and high repeatability.

2.2 Thermal Behavior

Drift ≤0.48%FS/°C, further improved with first-order compensation.

Tiempo de respuesta <2ms for rapid pressure changes.

2.3 Electrical Fit

Direct digital output to MCU reduces noise and power.

Low-voltage start-up enables quick wake-up.

Integración del sistema y diseño de micro bomba

Effective collaboration of sensor and pump hinges on gas routing, mechanical support, and EMC design.

Enrutamiento de gas: Short silicone tubing (≤5mm, Ø1.2mm) minimizes dead volume.

Montaje mecánico: Aluminum bracket with dual-layer damping foam reduces vibration.

Prácticas de EMC: Place filter caps and ground plane around digital lines to curb noise.

Calibración de firmware: Auto zero-point calibration at start-up with temperature drift compensation.

3.1 Gas Path Optimization

Chamber volume ≤10µL cuts residual air.

Low-adsorption tubing prevents gas retention.

3.2 Vibration Isolation & Thermal Control

Vibration damping pads lower mechanical noise.

Copper thermal pad under sensor fosters temperature uniformity.

3.3 Firmware Algorithms

Startup auto-calibration, continuous drift correction.

High-speed sampling with digital filters balances speed and stability.

Notas de instalación y soldadura

Proper placement and soldering are critical for performance and yield.

Orientación: Align top port toward pump path to avoid blockage.

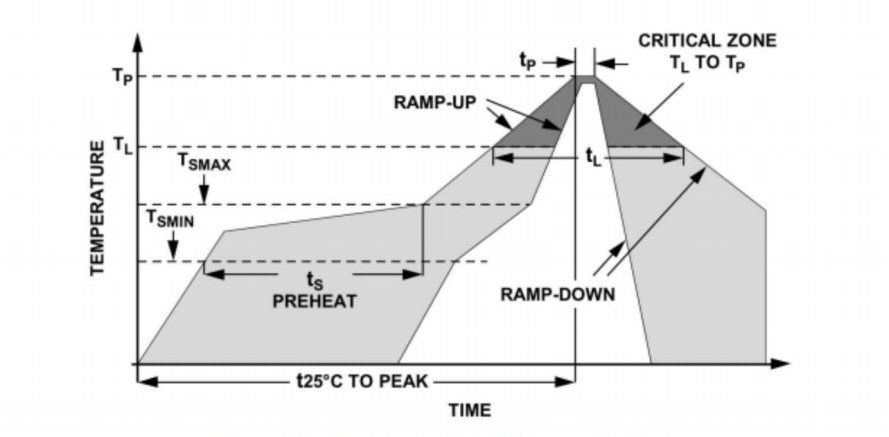

Perfil de reflujo: Peak ≤260°C with 10–20s in 230–260°C zone.

Pasta de soldadura: SnAgCu3.0, 45–75µm particles for reliable joints.

Diseño de almohadilla de PCB: Large ground pad beneath sensor for shielding, ground plane perimeter.

Polvo & Protección por humedad: Seal port promptly after placement to prevent contamination.

4.1 SMT Process Curve

Preheat: 120–150°C → Soak: 150–180°C → Reflow: 230–260°C → Cool, ≤4°C/s.

Paste thickness: 100–120µm.

4.2 Post-Reflow Inspection

AOI checks placement within 0.1mm tolerance.

X-ray confirms void-free solder joints.

Herramientas de pruebas de preproducción y medición

Before mass production, set up multi-stage tests to ensure consistency:

Cheque funcional: Calibrated gas source at 0/20/40kPa, record error across points.

Estrés ambiental: 85°C/85%RH for 48h to assess drift.

Vibración & Choque: 10–2000Hz @5g for 30min.

Cumplimiento de EMC: Radiated and conducted immunity per IEC61000-4.

Equipo:

Precision gas calibration bench (0.1Pa resolution).

High-speed DAQ (≥2kHz).

Automated test fixtures with board handling.

5.1 Calibration Workflow

Calentamiento 5min → Aplicar presiones estándar → Registro de salida → Linealidad de cálculo & offset → Generate calibration curve.

5.2 Data Traceability

Sensor batch coding for full trace.

Automated data logging into MES enables quality analytics.

Conclusión

This guide details an end-to-end solution for integrating WF3050D digital MEMS pressure sensors into smartwatch micro-pump blood pressure systems. Covering requirements analysis, sensor selection, system integration, installation best practices, and pre-production testing, it ensures miniaturization, low power, precision, and reliability—empowering engineers teams to deploy high-performance smartwatch blood pressure features with confidence.

La introducción anterior sólo toca la superficie de las aplicaciones de la tecnología de sensores de presión. Continuaremos explorando los diferentes tipos de elementos sensores utilizados en diversos productos, cómo funcionan y sus ventajas y desventajas. Si desea obtener más detalles sobre lo que se analiza aquí, puede consultar el contenido relacionado más adelante en esta guía. Si tiene poco tiempo, también puede hacer clic aquí para descargar los detalles de estas guías. Producto del sensor de presión de aire datos PDF.

Para obtener más información sobre otras tecnologías de sensores, por favor Visite nuestra página de sensores.