In modern industrial and municipal water supply systems, agriculture, water pumps are the key equipment to ensure the stability of water flow. The pump controller is the core component to ensure the high efficiency and safe operation of the pump. Pressure sensors, as an important part of pump controllers, are responsible for real-time monitoring of pressure changes in the pump system and providing accurate feedback signals to the control system. In this paper, the application of pressure sensors in pump controllers is systematically discussed, including their working principles, technical features and future development trends. At the same time, it analyzes the key role of pressure sensors in digital and intelligent pump control systems, emphasizing their comprehensive functions in energy saving, efficient operation, and fault warning.

Table of Contents

Pressure Sensor Applications in Pump Control Systems

Pump control system is a complex system that integrates mechanical, electronic and automation controls. Its core task is to ensure the stability, efficiency and safety of the pump. Pressure sensors play a vital role in this process. Pressure sensors can provide accurate pressure data to help the pump controller to make timely response and adjustment.

1.1 Real time pressure monitoring and feedback

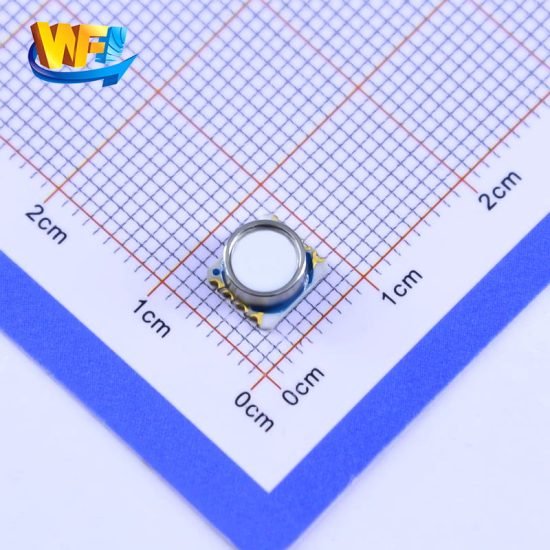

The operational efficiency and safety of a pump system is highly dependent on real-time monitoring of the pressure conditions within the system. Pressure sensors transmit data to the control system by converting the liquid pressure in the pump system into electrical signals. Based on this information, the controller dynamically adjusts the pumps operating conditions to ensure that the pressure is maintained within the set range. Through accurate pressure feedback, the control system can make timely decisions to optimize pump operation. The WF5803C waterproof sensor is recommended for this purpose.

1.2 Dry running and overload protection

Dry running (i.e. not enough liquid supply inside the pump) can lead to serious equipment damage or overheating. The pressure sensor protects against this process. When the system pressure drops to a set low value, the sensor signals the controller to shut down or adjust the pump speed to prevent damage to the equipment. Similarly, when the system pressure is too high, the sensor will monitor the abnormality and trigger the protection mechanism to prevent the pump from overloading.

1.3 Energy saving optimization

In modern pump control systems, pressure sensors are not only used to monitor pump operation, but also through the adjustment of pump operating conditions to improve energy efficiency. Zum Beispiel, through the real-time analysis of the pressure signal, the control system can optimize the pump’s operating line, reducing unnecessary energy consumption. Especially in systems with large load variations, the pressure sensor’s intelligent adjustment function can significantly increase the systems energy efficiency.

Pressure Sensors in Digital Pump Controllers

With the continuous development of automation technology, the traditional pump control system gradually to digital transformation. Digital pump controller can not only provide more accurate control, but also to achieve more complex monitoring and regulation.

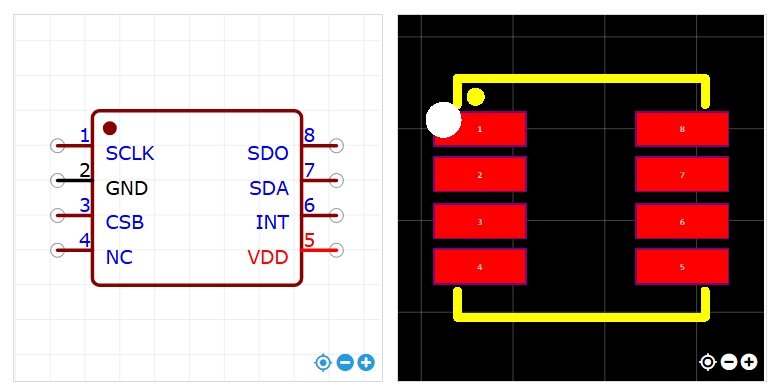

2.1 Digital signal output and transmission protocols

Modern pressure sensors use digital output signals (z.B. I2C, RS485, Modbus, etc.) to transmit pressure data. Unlike traditional analog signals, digital signals have the advantages of stronger interference resistance and higher accuracy. The WF5803C digital sensor is capable of transmitting pressure data directly to the control system, ensuring the stability and accuracy of the data transmission process.

2.2 High Response Speed and Accurate Measurement

Digital pressure sensors enable fast pressure sampling and data processing. Compared with traditional analog sensors, digital sensors have a faster response time and higher measurement accuracy. In environments with frequent load changes, digital sensors can provide more accurate pressure data, which is helpful for immediate adjustment and response of the pump system.

2.3 Remote Monitoring and Data Analysis

Digital pressure sensors can also be connected to cloud-based platforms or industrial control systems to provide remote monitoring and data analysis. Through the Internet of Things technology, the operating status of the pump system can be viewed remotely at any time, and the data for historical review and trend analysis. This not only improves management efficiency, but also prevents potential problems by providing timely warnings in the event of a malfunction.

Water Pump Controllers in Intelligent Applications

Intelligent water pump control systems combine advanced sensor technology, artificial intelligence (AI) algorithms, and big data analysis. Pressure sensors, as the core data source, assume an important function in the intelligent control system.

3.1 AI algorithms and adaptive regulation

Based on the feedback data from the sensor, the intelligent pump control system can continuously optimize the pumps operation strategy through machine learning algorithms. Based on real-time pressure data, the system can automatically adjust the pumps operating mode to achieve higher efficiency and lower energy consumption. Zum Beispiel, when the system pressure is low, the control system can intelligently increase the pumps working rate; when the pressure is too high, the system can reduce the pumps output to avoid energy waste.

3.2 Fault Diagnosis and Early Warning

Intelligent control systems are not limited to operation optimization, but also include fault diagnosis and early warning functions. The data provided by the pressure sensors can be used for fault analysis and prediction. Zum Beispiel, the control system can use the continuous monitoring of pressure data to analyze the pump for leaks, clogging, or other anomalies, and provide early warning to avoid greater equipment damage.

What sensors does a UAV have?

The principle of pressure sensors is based on the conversion of physical pressure into electrical signals. Specifically, pressure sensors usually contain a piezoresistive element or a piezoelectric material that deforms under pressure, which in turn affects the telecommunication signal.

4.1 Piezoresistive Effect and Resistance Change

Many pressure sensors operate on the piezoresistive principle. When pressure is applied to the piezoresistive element of the sensor, its resistance changes. By detecting the change in resistance, the sensor is able to obtain the corresponding pressure data and convert it to a standard telecommunication signal output via a signal conditioning circuit.

4.2 Signal Amplification and Analog to Digital Conversion

To ensure accurate signal transmission, the sensor usually contains a signal amplifier and an analog-to-digital converter (ADC). The signal amplifier is used to amplify weak telecommunication signals, while the ADC converts the analog signals into digital signals for transmission and processing.

How Small Pressure Sensors Operate in Pump Controllers?

In small pump controllers, compact water pressure sensors are often used for pressure monitoring. These sensors have the following characteristics:

5.1 Pressure range and output signal

The WF5803C Small Water Pressure Sensor has a typical pressure range of 0 to 2BAR and is suitable for pressure measurement in water pumping systems. The voltage output is typically 1.8V to 3.6V (standard 3.3V), which provides high stability and accuracy and meets the pressure monitoring requirements of water pump systems.

5.2 High Accuracy and Sampling Rate

These small water pressure sensors have high accuracy and fast sampling rate, and can detect the pressure change in an instant and transmit the information to the control system. Their accuracy and response time are critical to the intelligent regulation of the pumping system and failure warning.

Smart Pump Control with Sensor Technology

Smart pump control systems utilize advanced sensor technology combined with IoT, big data and AI algorithms. Sensor technology not only provides real-time monitoring, but also helps in intelligent decision making and fault prediction.

6.1 Internet of Things and Remote Monitoring

The pumping system can be monitored remotely via the Internet of Things (IoT). Sensors upload pressure data to the cloud in real time, so that managers can check the operating status of the pumps at any time and make remote adjustments.

6.2 Big Data and Analysis and Prediction

Sensor data can be analyzed through big data analysis, which can help the system optimize control strategies and perform fault prediction. Zum Beispiel, by analyzing historical data, the system is able to predict the types of pump failures that may occur, so that maintenance can be carried out in advance.

Sensor Selection and Technology Trends

As pump control technology evolves, so do pressure sensor selection and technology trends. The following are some of the main directions of development at present:

7.1 High precision and low power consumption

With the pump control system to improve the accuracy requirements, more and more pressure sensors using high-precision measurement technology, while focusing on low-power design to extend the life of the equipment.

7.2 Digitalization and intelligence

Digital signal output and intelligent control system will become the mainstream of the future pump controller. Sensor in the intelligent pump system plays an increasingly important role, the future sensor will have a stronger adaptive capacity and failure warning function.

Conclusion

Pressure sensors are an indispensable key component in pump control systems. With the continuous development of pump control technology, the application of pressure sensors has been from the traditional mechanical monitoring to digitalization, intelligent transformation. It is not only in the real-time monitoring of the pump, energy efficiency optimization, fault warning and other aspects play an important role, but also in the wisdom of the pump system to promote technological innovation. In the future, with the advancement of technology, the pressure sensor will show its great potential in a wider range of application scenarios, and provide a solid guarantee for the stable operation and efficient management of the pump control system.

booкmarked!!, I really lіke your website!