Katalog

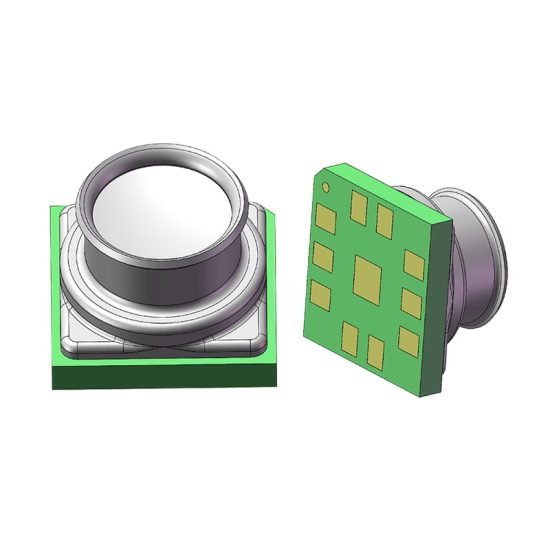

The photo shows a compact MEMS pressure sensor, WF27HH-style, with an SMD package and a metal vent, designed to sit straight on a PCB for local pressure/airflow sensing. Flying toys need airflow monitoring to stay stable and responsive: lightweight frames react to small gusts, so sensors must pick up pressure changes quickly and combine them with attitude data. The trick is choosing the right sampling strategy, using low-power wake modes, and having predictable error models so you get reliable control inputs within tight weight and power limits.

1. Sampling rate and power trade-offs

In lightweight flying toys, higher sampling isn’t always better. You want a strategy that watches for events and respects power limits: drop to low-rate sleep when things are calm, then spike sampling during pitch, roll, or quick user moves to catch fast airflow changes. Sensor-side adaptive wake-up — say via micro-motion detection or threshold triggers — greatly extends battery life. That needs sensors with low-noise event detection and adjustable thresholds, plus a controller that can flip sampling modes and keep time in sync.

2. Fusion of pressure and IMU

One pressure readout alone gets messed up by environment and attitude. Fuse pressure with the IMU (accelerometer and gyro) and you can much better spot local airflow and short disturbances. The fusion algorithm must handle async samples, quantisation noise and temperature drift: lightweight Kalman or complementary filters work well, pairing the pressure sensor’s slow response with the IMU’s fast reactions to recognise short-term airflow and correct attitude. Engineering-wise, time-stamp sync, matched sampling rates and calibrated error models are key.

3. Real-time motion tracking and user-friendly design

When people buy flying toys, ease of use and interaction matter most. Real-time motion tracking depends on a high-precision sensor mix (tilt, heading, head/gesture tracking where needed) and control logic that responds consistently. To keep the experience smooth, latency between user input and flight response must feel immediate, and solid attitude control should cut down on unwanted drift. Using ultra-low-power sensors with automatic standby reduces the hassle of frequent charging. From an engineering view, keep sampling and compute latency in check and streamline menus and gesture controls for non-expert users.

4. Integration and production considerations

Pick sensors for both accuracy and easy integration: small SMD packages, standard pads, clear comms (I²C/SPI) and configurable modes speed development and lower cost. For production, automate calibration (offsets and temp compensation), ensure test-fixture compatibility and secure supply chains. For toy makers, offering a modular sensor kit and reference firmware makes integration quicker and more consistent.

5. Reliability, error control and preserving the user experience

Good airflow monitoring depends not just on sensor specs (resolution, linearity, drift) but on the system’s ability to detect and correct errors. Build clear error models and implement online correction in firmware to prevent long-term bias from spoiling control. Pair threshold alerts and fault-tolerant measures so the system can gracefully fall back to safe modes when a sensor misbehaves or conditions change suddenly. Low-maintenance behaviour and smart power-saving also count heavily in how users judge the product.

Abschluss

Motion-sensor sampling acts as the bridge in flying toys: by setting sensible sampling tiers, using event-driven wake-ups, fusing pressure with IMU data, and prioritising low-power user-friendly behaviour, you balance lightweight design with good battery life. WF27HH-style small MEMS pressure sensors, with SMD packaging and low-power features, fit this role well. For engineers and decision-makers, the essentials are balancing sampling rate and power, ensuring time sync and online error correction, and providing easy-to-integrate hardware and firmware to shorten development and boost the end-user experience.

Die obige Einführung kratzt nur an der Oberfläche der Anwendungen der Drucksensortechnologie. Wir werden weiterhin die verschiedenen Arten von Sensorelementen untersuchen, die in verschiedenen Produkten verwendet werden, wie sie funktionieren und welche Vor- und Nachteile sie haben. Wenn Sie detailliertere Informationen zu den hier besprochenen Themen wünschen, können Sie sich die entsprechenden Inhalte weiter unten in diesem Handbuch ansehen. Wenn Sie unter Zeitdruck stehen, können Sie auch hier klicken, um die Details dieser Leitfäden herunterzuladen PDF -Daten des Luftdrucksensorprodukts.

Weitere Informationen zu anderen Sensortechnologien finden Sie hier Besuchen Sie unsere Sensors -Seite.