Modern breast pumps are no longer just about simple suction control. With the advancement of smart technology, they now prioritize precision, comfort, and efficiency. Integrating Drucksensoren into breast pumps allows real-time suction monitoring and automatic adjustments, ensuring stable milk extraction while minimizing discomfort or potential nipple damage. This article explores how the WF100DPZ Digitaler Drucksensor Verbessert die intelligente Brustpumpe -Technologie durch Bereitstellung precise, stable, and intelligent suction control.

Katalog

Arbeitsprinzip von Drucksensoren in Milchpumpen

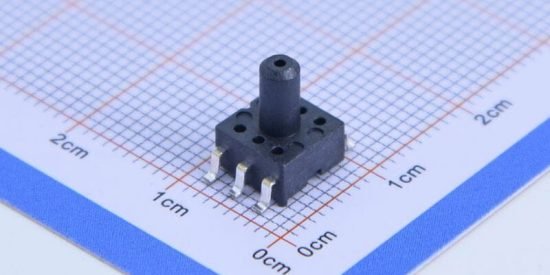

The core function of a breast pump is to create controlled negative pressure that mimics a baby’s natural suction pattern. The WF100DPZ -Drucksensor, which utilizes Piezoresistive Silizium-Mikro-Maschinationstechnologie, ensures precise pressure measurement and adjustment through:

- Echtzeitdrucküberwachung: With a 24-bit Σ-Δ ADC, it provides high sensitivity (0.027 Pa/LSB), enabling ultra-smooth and controlled suction cycles.

- Automatische Sauganpassung: The sensor transmits data via I2C/SPI -Schnittstelle to the control system, allowing for dynamic suction adjustment, making the experience more natural and comfortable.

- Temperaturkompensation und langfristige Stabilität: Operating across -40°C bis 125°C, the sensor ensures stable performance in various environments, while its high linearity (≤0.5% FS error) guarantees long-term accuracy.

Die Bedeutung der intelligenten Anpassung von Milchpumpen

Breastfeeding is vital to the health of babies, but many mothers need to use breast pumps for milk collection due to work, nipple sensitivity, or unstable breast milk production. However, traditional breast pumps often have the following problems:

- Fixed suction force, lack of personalized adjustment

- Fixed suction mode may lead to nipple pain or insufficient stimulation, affecting milk secretion.

- Cumbersome operation, manual adjustment is inconvenient

- Users need to constantly manually adjust the suction force and rhythm, the use of experience is poor.

- Kein Datenfeedback zur Optimierung des Brustpumpenprozesses

- Traditional breast pumps cannot record usage data, making it difficult to optimize the personalized breast pumping mode.

With the help of pressure sensors, smart breast pumps can accurately monitor the changes in breast pressure during breast pumping and adjust suction and rhythm according to real-time data, making the whole process more efficient, comfortable and safe.

Rolle von Drucksensoren bei intelligenten Milchpumpen

Pressure sensors are a kind of sensing devices that can detect changes in external pressure and convert them into electrical signals. In the smart breast pump, the pressure sensor is mainly responsible for the following tasks:

1. Monitor the change of breast pressure

During breast pumping, the breast is affected by the pressure, too much pressure may cause pain, too little pressure can not effectively stimulate milk secretion. The pressure sensor can accurately measure the pressure on the breast and provide real-time feedback.

2.Automatic adjustment of suction

Based on the breast pressure data, the smart breast pump can dynamically adjust the suction force so that it can effectively express milk without causing discomfort. Some high-end breast pumps can also gradually optimize the suction mode according to the user’s historical use data.

3. Recognize the state of milk flow

The pressure sensor can be combined with the flow sensor to determine the state of milk flow. When the milk flow is reduced, the breast pump can increase the stimulation mode to promote milk secretion.

4.Data Recording and Analysis

Modern Smart Breastpump can be connected to the mobile app via Bluetooth or Wi-Fi, so that users can view the data of pressure changes during breast pumping to understand the optimal breast pumping mode and make adjustments accordingly.

Arbeitsmodi der intelligenten Brustpumpe

Based on the pressure sensor, Smart Breast Pump can realize the following intelligent working modes:

1. Adjustment Mode

The breast pump can automatically match the optimal suction force according to the user’s needs. For example, the user can select “Comfort Mode” or “High Efficiency Mode” in the mobile app, and the breast pump can automatically adjust the suction strength and frequency.

2. Dual Stage Breast Pumping Mode

- Many high-end smart breast pumps use a “dual stage” mode:

- Stimulation Mode: simulates a baby’s rapid sucking to increase the activity of the mammary glands and promote the flow of breast milk.

- Breast pumping mode: Once the milk starts to flow, the breast pump switches to a slower but deeper suction mode to increase the efficiency of breast pumping.

3. Adaptive Rhythm Mode

With the real-time data from the pressure sensor, the breast pump can gradually adjust the rhythm of breast pumping to better match the characteristics of the user’s milk secretion. For example, some users need higher suction power at the beginning of breastfeeding and lower suction power at the end of breastfeeding, the smart breast pump can automatically adapt to this need.

4. Prevent excessive suction mode

When excessive breast pressure or nipple stretching is detected, the pressure sensor automatically reduces suction to prevent nipple damage. This feature is especially important for new mothers to relieve nipple sensitivity.

Wichtige Vorteile der Verwendung von Drucksensoren in intelligenten Brustpumpen

Personalisiertes Saug für einen verbesserten Komfort

Traditional breast pumps rely on manual adjustments, which may not suit every mother’s needs. With Echtzeit-Drucksensoren, the pump can analyze Milchfluss und Saugdruck, automatically adjusting the suction mode to match the user’s comfort level, reducing pain and increasing efficiency.

Präzise Saugkontrolle für eine schnellere Milchgewinnung

Der WF100DPZ -Sensor stützt Druckbereiche bis zu 300kPa, ensuring that the pump maintains a stabile und optimierte Saugkurve, improving milk extraction efficiency while reducing overall pumping time.

Verhinderung von Überstiegs- und Brustwarzenschaden

Übermäßiger Saug kann verursachen Brustwarzenschmerzen oder Kanalblockaden, which are common concerns among breastfeeding mothers. The Drucksensor überwacht aktiv die Druckpegel, automatically adjusting suction strength to prevent discomfort and protect breast health.

Smart Milk Management mit Datenvisualisierung

Wenn integriert in IoT -Technologie, the pressure sensor allows for Echtzeitdatenübertragung to a smartphone app, enabling users to monitor Saugtrends und Milchflussanalyse—offering valuable insights into their breastfeeding patterns.

Abschluss

Die Entwicklung intelligenter Brustpumpen ist eng mit den Fortschritten in verbunden Hochvorbereitungsdrucksensortechnologie. The WF100DPZ Digitaler Drucksensor fällt mit seinem auf real-time monitoring, intelligent adjustment, and low-power operation, providing a more natural, efficient, and comfortable pumping experience. As sensor technology continues to improve, future breast pumps will become even more Personalisiert und intelligent, catering to diverse breastfeeding needs and setting new standards in maternal and infant health innovation.

Die obige Einführung kratzt nur an der Oberfläche der Anwendungen der Drucksensortechnologie. Wir werden weiterhin die verschiedenen Arten von Sensorelementen untersuchen, die in verschiedenen Produkten verwendet werden, wie sie funktionieren und welche Vor- und Nachteile sie haben. Wenn Sie detailliertere Informationen zu den hier besprochenen Themen wünschen, können Sie sich die entsprechenden Inhalte weiter unten in diesem Handbuch ansehen. Wenn Sie unter Zeitdruck stehen, können Sie auch hier klicken, um die Details dieser Leitfäden herunterzuladen PDF -Daten des Luftdrucksensorprodukts.

Weitere Informationen zu anderen Sensortechnologien finden Sie hier Besuchen Sie unsere Sensors -Seite.