The proper functioning of ventilation systems is essential in construction, industrial production and in all kinds of machinery and equipment. Ventilation systems not only ensure air circulation, but also play an important role in controlling temperature, humidity and air quality. In order to ensure the high efficiency and stability of the ventilation system, accurate pressure monitoring is indispensable. High-precision pressure sensors play a vital role in this process, accurately detecting and controlling pressure changes in the ventilation system to ensure that the system operates at its optimal level.

For engineers or technicians, the following questions may arise:

- Why are high-precision pressure sensors important for ventilation systems?

- How to choose the right pressure sensor to monitor the pressure in the ventilation system?

- How to ensure the accuracy and stability of high-precision pressure sensors in ventilation systems?

Beginnen wir mit dem Verstehen!

Katalog

The Role of High-Accuracy Pressure Sensors in Ventilation Systems

High-accuracy pressure sensors play an important role in ventilation systems, mainly in the following aspects

1.Ensuring stability and uniformity of air flow

One of the main tasks of a ventilation system is to ensure the flow of air into and out of the room, and the stability and uniformity of the air flow is usually closely related to pressure. High-precision pressure sensors allow real-time monitoring of pressure changes in different areas of the system, ensuring uniformity and stability of airflow.

2.Improve system energy efficiency

Accurate pressure monitoring can optimize the workload of the air handling system to avoid over- or under-pressurization, improving energy efficiency and reducing unnecessary energy consumption.

3.Prevents equipment damage

Fans and air handling units in the ventilation system can be affected by over- or under-pressure. The use of high-precision pressure sensors can detect these pressure fluctuations in a timely manner, preventing equipment damage and improving system reliability.

4.Ensure air quality

Maintaining a proper pressure differential prevents external contaminants or harmful gases from entering the room and ensures that the ventilation system is able to effectively remove exhaust gases and maintain air quality.

How high accuracy pressure sensors work

High-accuracy pressure sensors detect and measure pressure changes in gases or liquids and convert them into electrical signals that can be processed by a system. The core principle is usually based on resistance, capacitance, or the piezoelectric effect:

Resistive Strain Principle

The sensor has an internal strain gauge which, when pressure is applied to the surface of the sensor, causes the material to deform, changing the resistance value. The change in resistance is measured to determine the change in pressure.

Capacitive Principle

In some high-precision sensors, the inner part of the sensor consists of two electrode plates. As the external pressure changes, the distance between the electrodes changes, resulting in a change in capacitance, and the change in capacitance is used to determine the pressure.

Principle of Piezoelectric Effect

A piezoelectric material deforms under external pressure and generates an electrical charge. The sensor reflects the change in pressure by detecting this change in charge.

Common Pressure Monitoring Methods

Static Pressure Monitoring

Static pressure is one of the most common types of pressure in ventilation systems and is usually measured by means of a static pressure sensor. This type of sensor directly monitors the static pressure in the air and is used to evaluate air flow and equipment operation.

Differential Pressure Monitoring

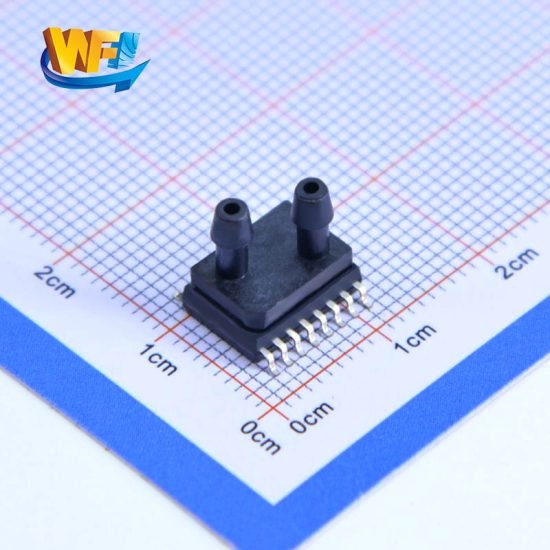

The WF200 series of Differentialdrucksensoren are capable of monitoring the pressure difference between two different locations within a system. Differentialdrucksensoren are widely used in ventilation systems to detect the direction of air flow, clogging of filters, and so on.

Dynamic Pressure Monitoring

Dynamic pressure monitoring is commonly used to capture pressure fluctuations in ventilation systems, and is suitable for situations that require high response speed and accuracy, reflecting pressure changes in the system in real time.

Key Points for Selecting High Accuracy Pressure Sensors

The following key factors should be considered when selecting a suitable high accuracy pressure sensor:

Range and Accuracy

When selecting a pressure sensor, make sure that its range is appropriate for the operating pressure range of the ventilation system. At the same time, accuracy is the key to ensuring proper system operation, and a sensor with the appropriate accuracy should be selected based on the requirements of the ventilation system.

Corrosion Resistance and Environmental Adaptability

Ventilation systems often involve moisture in the air, corrosive gases, and other environmental factors, so the sensor needs to have strong corrosion resistance and high temperature resistance to ensure its long-term stability.

Ansprechzeit

The response time of high-accuracy pressure sensors is particularly important for ventilation systems, especially those that require rapid adjustment of airflow or pressure. Therefore, the response time of the sensor must be short enough to ensure that the system makes adjustments in a timely manner.

Signal Output

Different pressure sensors have different signal outputs, such as analog signal outputs (voltage or current) and digital signal outputs (e.g. I2C, RS485). Choosing the appropriate signal output will ensure compatibility between the sensor and the control system.

Examples of high accuracy pressure sensors in ventilation systems

HVAC (Heating, Ventilation and Air Conditioning) System

In HVAC systems, high accuracy pressure sensors are widely used for air flow monitoring, air quality testing, equipment maintenance and system optimization.

Clean room ventilation system

In demanding environments such as clean rooms, pressure sensors help monitor the pressure difference between the inside and outside of the room to ensure that contaminants are not allowed to enter and that the air quality in the clean room is maintained.

Industrial Ventilation

In some industrial manufacturing facilities, ventilation systems must not only exhaust fumes, but also maintain proper airflow pressure. High accuracy pressure sensors can monitor and adjust the pressure in real time to ensure the safe operation of the equipment.

Care and Maintenance of High Accuracy Pressure Sensors

Periodic Calibration

High accuracy pressure sensors require periodic calibration to ensure the accuracy of the measurement results. Calibration is usually carried out in a stable environment and is adjusted periodically based on actual usage.

Cleaning and Inspection

Keep the surface of the sensor clean to prevent dust and dirt from affecting measurement accuracy. Also, check the sensor and its connections regularly to ensure that they are in good working order.

Inspection of piping

Pipes and connections in the ventilation system may leak or become loose, affecting the measurement of the pressure sensor. Check these connections regularly to ensure that the system is well sealed.

FAQ

What should I do if the pressure sensor is not accurate enough?

- If the accuracy does not meet the requirement, the sensor may be aged or not calibrated accurately. It is recommended to calibrate the sensor periodically and check whether the sensor needs to be replaced.

How to deal with the unstable signal output of the pressure sensor?

- Unstable signal output may be related to the sensor itself or the connection cable. Check the signal transmission path and make sure the electrical connection is secure.

How to improve the durability of pressure sensors?

- Select sensors that are resistant to corrosion and high temperatures, and perform regular maintenance and inspections to extend their service life.

Abschluss:

Die Verwendung von high accuracy pressure sensors in ventilation systems greatly improves system stability and efficiency. Accurate pressure monitoring ensures the proper operation of the ventilation system and prevents equipment failure or wasted energy due to pressure abnormalities. Choosing the right sensors, with regular maintenance and calibration, not only ensures long-term system reliability, but also protects air quality and the safety of the operating environment.

boоkmarked!!, I love your site!