Katalog

1. Measurement Principles of the Chip in Pneumatic Presses

1.1 Chip Package Overview

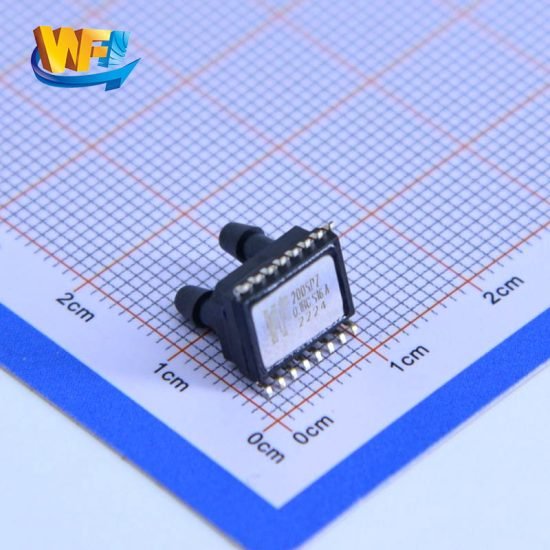

The MEMS differential pressure sensor chip in comes in an SOP16 or DFN package with dual micro-port barbs for pressure lines, directly SMD-mounted on PCBs. Pads on the chip bottom provide power, signal, and ground connections.

1.2 Microstructure and Strain Detection

A thin silicon diaphragm sits between two micro-cavities. Differential pressure causes micron-scale deflection, sensed by an integrated resistive bridge or capacitive element and converted into an electrical signal.

1.3 Signal Conditioning and Output

Built-in low-noise amplifiers and temperature compensation circuits output a standard 0.5–4.5 V analog signal or optional I²C/SPI digital interface, ready for PLC or embedded MCU integration.

1.4 Temperature Drift and Linearization

Calibration data stored in on-chip EEPROM compensates for temperature drift and zero offset, ensuring accuracy better than 0.2% FS from -40 °C to +125 °C.

2. Performance Advantages and Requirements

2.1 High Integration and Lightweight

The chip’s compact package and micro-barb ports reduce volume and weight, ideal for miniaturized pneumatic modules.

2.3 Vibration and Shock Resistance

The silicon MEMS structure resists up to 20 g shock and 10 g vibration, adapting to the dynamic switching of pneumatic presses.

2.4 Cost-effectiveness and Mass Production

Standard semiconductor fabrication and SMD assembly drive down per-unit costs, enabling scalable deployments.

3. Mounting and Reflow Soldering Considerations

3.1 PCB Design and Layout

Allocate clearance around the chip for unobstructed port access.

Design pads per manufacturer recommendations and compatible with no-clean, lead-free reflow paste stencils.

3.2 Reflow Profile Control

Peak temperature below 260 °C, with a total reflow time under 60 s.

Solder the electrical pads first, then secure the port interfaces with low-temperature adhesive or localized soldering.

3.3 Tubing Connection and Sealing

Use soft silicone tubing sized to fit micro-barbs with at least 3 mm insertion depth.

Reinforce connections with miniature clamps or heat-shrink tubing to prevent vibration-related loosening.

3.4 ESD and Cleaning

Follow strict ESD protocols before and after placement, and remove flux residue with ionized air or IPA.

Avoid chlorine-based cleaners to protect MEMS structures.

4. Case Studies and Performance Validation

4.1 Small-scale Pneumatic Assembly Monitoring

On a smart device housing line, the sensor chip tracked cylinder force to ensure proper insertion, boosting yield by 5%.

4.2 Online Diagnosis and Alerts

Deviation of 10% from nominal differential pressure triggers system alerts for potential line blockages or leaks, enabling fast maintenance.

4.3 Data Integration and Cloud Platform

I²C data is converted by an MCU and sent via MQTT to the cloud, where analytics predict equipment health.

4.4 Long-term Stability Testing

After 3000 hours of operation, drift remained under 0.5% FS, confirming suitability for high-cycle applications.

Abschluss

The MEMS differential pressure sensor chip in offers compact integration, rapid response, robust interference immunity, and cost-effective mass production for pneumatic press applications. Proper PCB layout, controlled reflow soldering, secure tubing, and ESD practices are essential to ensure reliable performance. This solution provides precise, lightweight, and efficient monitoring support for automated assembly processes.

Die obige Einführung kratzt nur an der Oberfläche der Anwendungen der Drucksensortechnologie. Wir werden weiterhin die verschiedenen Arten von Sensorelementen untersuchen, die in verschiedenen Produkten verwendet werden, wie sie funktionieren und welche Vor- und Nachteile sie haben. Wenn Sie detailliertere Informationen zu den hier besprochenen Themen wünschen, können Sie sich die entsprechenden Inhalte weiter unten in diesem Handbuch ansehen. Wenn Sie unter Zeitdruck stehen, können Sie auch hier klicken, um die Details dieser Leitfäden herunterzuladen PDF -Daten des Luftdrucksensorprodukts.

Weitere Informationen zu anderen Sensortechnologien finden Sie hier Besuchen Sie unsere Sensors -Seite.