Die Kernaufgabe von Drucksensoren ist die Einstellung der Temperatur-Tiefenerkennungskamera

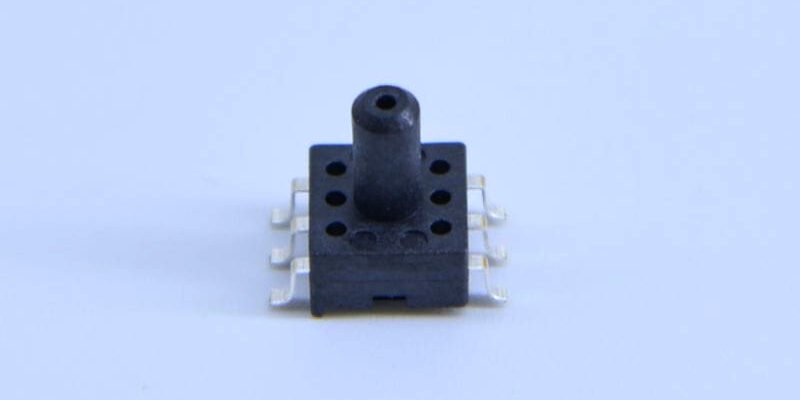

Pressure sensors act as the depth-sensing hub for underwater cameras: they deliver depth and pressure data, enable image-parameter adaptation, support housing safety and feed motion control and long-term health monitoring.