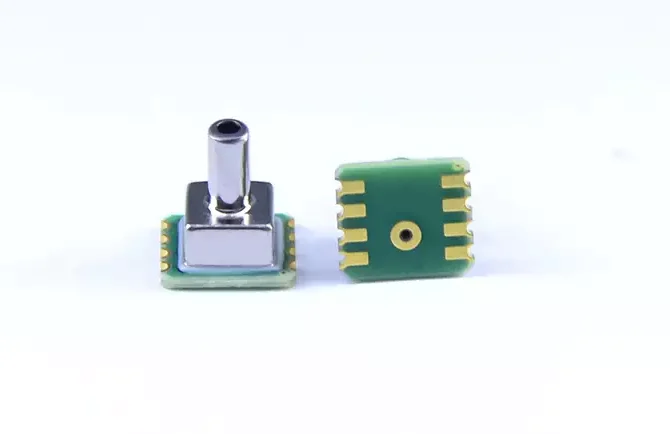

Positive and Negative pressure sensor in breast pump-Best Application

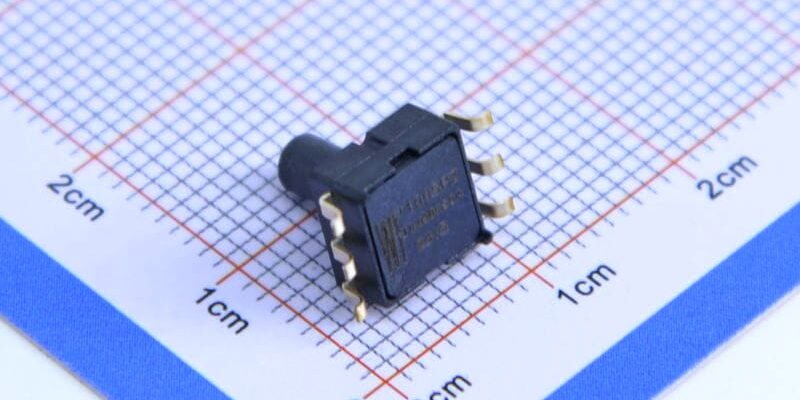

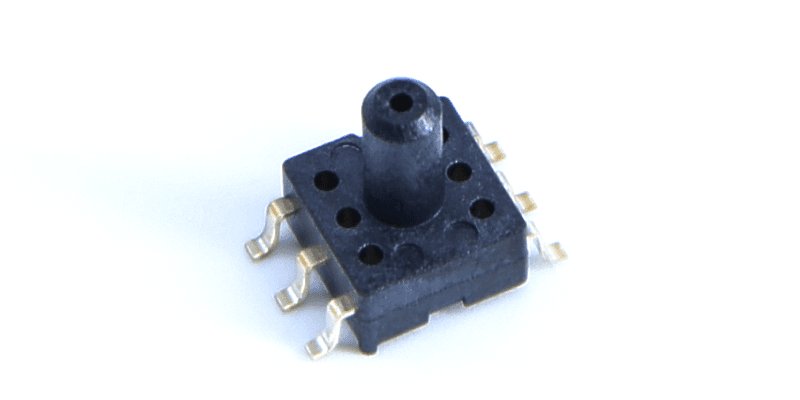

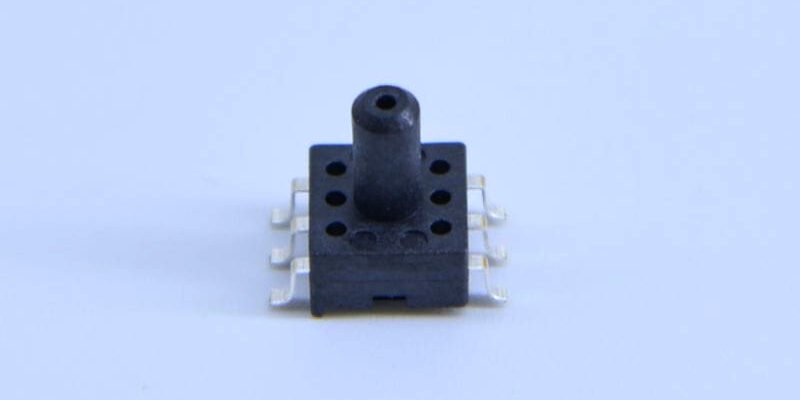

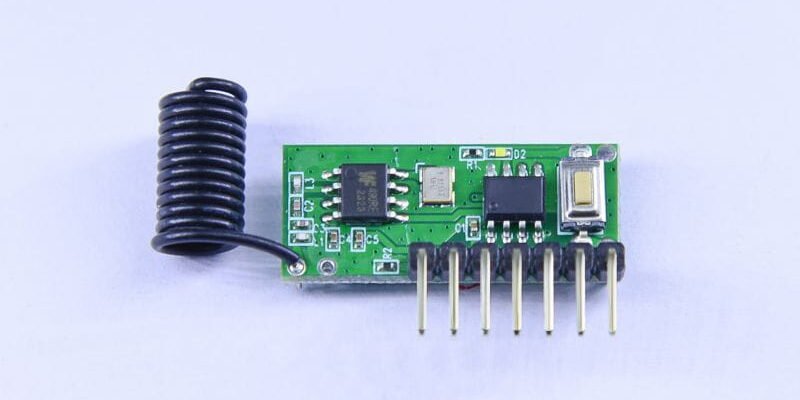

Positive and negative pressure sensors are used to monitor the air pressure changes inside the breast pump to ensure that the suction force during breast pumping meets the expectations and is adjusted in a timely manner to avoid too much or too little suction force, thus effectively improving the efficiency of breast pumping and ensuring comfort.

Positive and Negative pressure sensor in breast pump-Best Application Læs indlæg »