Katalog

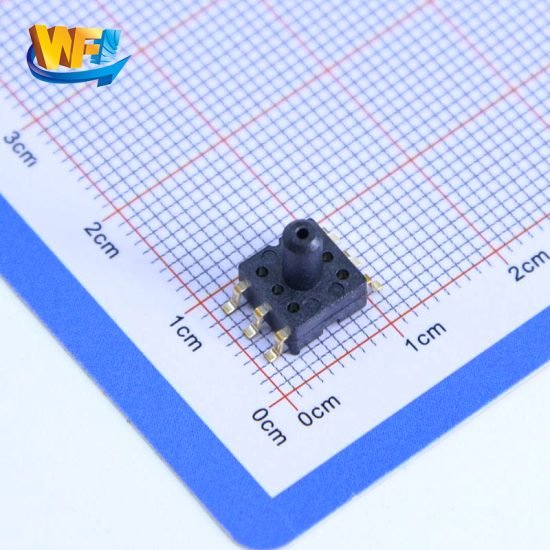

A small-size SOP-packaged pressure sensor with a single-port design, built-in amplifier, and multi-stage pressure–temperature compensation algorithm. It supports analog output that provides an amplified and calibrated pressure signal. The product is compatible with 3.3V/5V power, features gold-plated leads for reliable soldering and oxidation resistance, and is suitable for consumer, medical, and industrial scenarios. This article examines package and electrical interfaces, compensation strategy, production and calibration control, application fit, and engineering integration — helping technical personnel quickly assess design and deployment considerations for such devices.

1. Packaging and mechanical/electrical interfaces

Package layout, port orientation, and lead finish

The compact SOP single-port package significantly saves PCB area and simplifies mechanical alignment. Gold-plated leads reduce oxidation and improve reflow-weld reliability. The sensing die is silicon-based, and the top single port facilitates gas or liquid pressure ingress; package materials such as PPS ensure long-term thermal resistance and mechanical strength. For engineers, critical considerations include port orientation and routing, pad footprint, and plating consistency of the leads — all directly affect assembly yield and long-term drift. This section emphasizes how packaging influences manufacturability and field reliability.

2. Multi-stage compensation strategy and amplifier circuitry

Onboard amplification plus layered pressure–temperature correction

The integrated multi-stage pressure–temperature compensation combines a hardware amplifier, primary calibration coefficients, and secondary temperature correction to amplify microvolt-level signals from the sensor die into a directly usable analog voltage. The compensation algorithm corrects nonlinearity and temperature drift across -20°C to +85°C, and, together with per-unit factory calibration data, achieves high-accuracy outputs. For system designers, it is essential to understand the sensor’s gain, output scaling, and calibration points so that the analog output can be seamlessly connected to a microcontroller ADC or a downstream amplifier. This design significantly reduces the need for external board-level calibration and complex compensation algorithms.

3. Production-to-shipment quality control

Layered tests, per-unit calibration, and traceability

From die packaging and wire bonding to package sealing and calibration, the manufacturing workflow must include layered quality checks: device-level linearity and temperature-drift tests, package leak and mechanical stress inspections, and final temperature cycling plus calibration verification. By extracting the amplified analog signal on the assembly line for per-unit comparison and storing calibration parameters, manufacturers can assure outbound consistency and traceability. Engineering procurement and quality teams should require batch test reports and calibration certificates from suppliers to facilitate quick fault localization during system integration and to maintain long-term operational reliability.

4. System-level integration and power compatibility

Supply options, grounding, and ADC matching

These sensors support 3.3V and 5V supply options; the wide voltage compatibility eases system power design constraints and fits both low-power mobile platforms and traditional industrial control systems. The analog output can be customized to a specified voltage range to match various ADC reference voltages. Practical system integration concerns include supply filtering and reference stability, separation of analog and digital grounds, and matching the amplifier output bandwidth with sampling rates to ensure fast response and low-noise acquisition. PCB layout and grounding strategy directly determine final SNR and measurement accuracy.

5. Typical performance metrics and engineering considerations

Range, resolution, and what to verify during integration

Key specs cover range options (selectable from -100 kPa to 1000 kPa), high effective resolution (up to 24-bit-equivalent processing), linearity, temperature drift, and response time. Gold-plated leads and PPS packaging ensure long-term reliability and low contact resistance. Engineers should pay attention to how calibration curves are stored, whether temperature compensation parameters are retained internally, and if the analog output requires extra anti-interference filtering. Choosing the appropriate output voltage span and filter topology for the target application can materially improve measurement stability and consistency without raising system cost.

Konklusion

Small-size SOP-packaged pressure sensors with integrated multi-stage compensation move hardware amplification and temperature/pressure compensation inside the device, reducing system complexity and improving outbound consistency. The primary advantages are PCB-level ease of integration, fast response, customizable output voltage, and the long-term reliability of metalized leads. Engineers and technical decision-makers should focus on package orientation and layout, availability of consistent calibration data, power and grounding design, and matching ADC input scaling to ensure rapid, reliable deployment that meets performance targets.

Ovenstående introduktion ridser kun overfladen af anvendelserne af tryksensorteknologi. Vi vil fortsætte med at udforske de forskellige typer sensorelementer, der bruges i forskellige produkter, hvordan de virker, og deres fordele og ulemper. Hvis du gerne vil have flere detaljer om, hvad der diskuteres her, kan du tjekke det relaterede indhold senere i denne vejledning. Hvis du er presset på tid, kan du også klikke her for at downloade detaljerne i denne guide Lufttrykssensor Produkt PDF -data.

For mere information om andre sensorteknologier, venligst Besøg vores Sensors -side.