- Ved WFsensorer

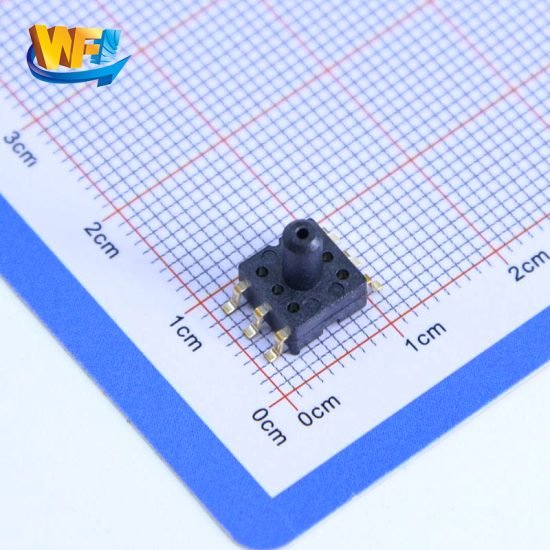

In pumped gas detectors, steady and accurate sampling decides how trustworthy the readings are and ultimately keeps people safe. Pressure sensors — especially piezoresistive ones — play the key role of monitoring vacuum and back-pressure in the gas path in real time. This piece approaches the topic from sensor function, range and accuracy matching, environmental robustness, signal conditioning and system integration, offering practical, engineer-oriented guidance. Based on examining the uploaded image of common SMD pressure sensors (top-port, 6-pin/side-pin layouts), we discuss how to keep sampling quality consistent in pumped applications, reducing false alarms and missed events. When inflating car tyres, timely and accurate pressure feedback directly affects safety and ride comfort. This piece looks at monitoring tyre pressure changes while using an air pump from the viewpoint of the sensor: how sensor characteristics and pump mechanics tie together to deliver stable, repeatable control. We run through sensitivity, response time, temperature stability and packaging protection, and give selection and installation advice so engineers can make better choices when designing pump systems or portable inflators.

Katalog

1. The core duties of inlet vacuum monitoring

inlet vacuum, blockage detection

The sensor at the inlet acts as the system’s “flow guard”, measuring vacuum at the intake to reflect changes in sampling path resistance. Typical operating vacuum sits around −10 to −20 kPa; if vacuum climbs toward −25 kPa you should be alert, and around −35 kPa is a common threshold to trigger a blockage or low-flow alarm. Accurate inlet vacuum monitoring gives immediate notice of filter saturation, kinked tubing or probe blockage, ensuring the detector responds promptly and readings stay truthful. Sensor resolution, stability and dynamic response directly affect the reliability of flow-judgement algorithms, so pick devices with low drift and fast response in the relevant range. The SMD sensors shown in the image have a small top-port suited to installation downstream of the inlet filter, so they’ll measure the true inlet vacuum and react quickly to resistance changes.

How to set inlet alarm thresholds to balance sensitivity and stability

Alarm thresholds at the inlet should be based on the system’s static resistance and the typical operating vacuum profile. Too low a threshold leads to nuisance alarms and poor maintainability; too high risks delaying response to real blockages and compromising safety. Run factory trials to map normal behaviour, then use a two-stage threshold: a warning (e.g. −25 kPa) to prompt inspection, and a critical level (e.g. −35 kPa) to force action such as filter replacement. Combine thresholding with time-window logic (ignore short spikes, trigger on sustained exceedance) and flow-recovery checks to cut down false positives while keeping alarms timely and trustworthy.

2. Exhaust back-pressure monitoring and pump protection

A sensor on the pump’s exhaust keeps watch over back-pressure. If the exhaust is blocked or vents into a confined space, rising back-pressure stresses the pump and fittings. Monitoring exhaust pressure lets the system trigger over-pressure protection (slow down, stop, or alert) to prevent damage. Back-pressure data can also indicate constrained discharge conditions, helping engineers redesign exhaust paths or fit better venting. The sensor must be linear in the positive pressure range, withstand transient over-pressure events and remain stable across temperature swings.

Response strategies for back-pressure and pump protection

A sensible protection scheme uses three steps: early warning, soft shutdown and full stop. At the warning level instruct the operator to inspect the exhaust; at the next level reduce pump speed or switch to intermittent sampling; at extreme values stop the pump and log an error. This requires a sensor that can flag overrange conditions and tolerate short pressure spikes without being destroyed, so you avoid false trips and component damage.

3. Why choose piezoresistive pressure sensors: range matching and environmental robustness

MEMS piezoresistive, range matching, digital output

Piezoresistive MEMS sensors are widely chosen for pumped gas detectors because they offer compact ±5 PSI (≈±35 kPa) ranges that neatly cover typical inlet vacuum and alarm points. Modern piezoresistive parts can show total error bands down to ±1.5% FSS, wide operating temperatures (−40°C to +110°C) and strong shock tolerance, so they remain reliable in field or industrial settings. Digital outputs (24-bit ADC over I²C or SPI) cut analog chain noise and simplify MCU interfacing, improving interference immunity and repeatability. Small, PCB-mountable packages support compact, portable detector designs.

Recommendations for digital outputs and electrical interfaces

When picking a digitally outputting piezoresistive sensor, favour high-resolution ADCs and configurable filtering/timing so you can tune sampling strategies. I²C is fine for short, low-speed links and when multiple sensors share a bus; SPI gives greater robustness in noisy environments. Power supply noise affects digital readings too, so use solid bypassing, careful ground layout and common-mode suppression to keep noise out of the measurements and ensure long-term stability.

4. System integration: signal conditioning, temperature compensation and anti-interference design

Even with a top-class sensor, system-level design determines final sampling quality. Temperature is the main driver of long-term drift for piezoresistive devices; tackle it via hardware compensation or software calibration curves to limit zero-point shift and sensitivity change. Signal conditioning should combine hardware and software filtering plus outlier rejection; tune sample rate and averaging to keep response snappy while suppressing noise. For I²C/SPI buses use shielding, proper pull-ups/pull-downs and, where needed, differential signalling or bus termination to strengthen communications. Validate your design with pressure-shock tests and field trials to make sure the detector keeps sampling stably under typical and extreme conditions.

Data processing and filtering strategies for noisy field conditions

In the face of transient pulses, mechanical vibration or EMI, hardware filtering alone often won’t cut it. Use layered filtering: median or spike rejection to remove short transients; sliding-window averaging or exponential smoothing to reduce noise while retaining trends; and threshold-based event detection that triggers special handling when limits are broken. Combine sensor self-diagnostics (overrange flags) with time-consistency checks (ignore very brief excursions, alarm on sustained exceedance) to raise usable reading rates and cut false alarms.

5. Maintenance, calibration and on-site reliability verification

Long-term stable sampling depends not only on the sensor but also on proper maintenance and calibration. Adopt a tiered calibration schedule based on usage intensity: quick automatic offset checks to handle temperature drift, and periodic traceable calibration (every six or twelve months) to keep accuracy in check. Link filter, hose and probe maintenance to alarm logs: sustained inlet vacuum rise that reaches the warning threshold should prompt cleaning or replacement, and automatically create a maintenance ticket for traceability. Field verification should include temperature cycling, vibration and rapid pressure-step tests to confirm the instrument’s steady sampling capability in real operating conditions.

Suggested calibration and maintenance workflow

Implement a routine with power-on self-tests, baseline pressure capture and incremental calibration to reduce drift effects. On startup record a short baseline in unloaded conditions and, if baseline offsets exceed a preset limit, prompt a maintenance reminder or trigger an internal recalibration. Long-term trend logs and alarm histories help spot gradual clogging or sensor degradation early so you can move to predictive maintenance and reduce downtime.

Konklusion

In pumped gas detectors, pressure sensors are central to achieving stable, accurate sampling. By matching the right piezoresistive sensor range, using digital outputs and robust signal conditioning, applying temperature compensation and sensible alarm thresholds, engineers can noticeably improve sampling reliability and maintainability. With the SMD top-port package shown in the image, place sensors thoughtfully (after the inlet filter and at the exhaust) and adopt sound calibration and maintenance practices to minimise false and missed alarms and protect the pump — delivering long-term, dependable sampling performance for the detector.

Ovenstående introduktion ridser kun overfladen af anvendelserne af tryksensorteknologi. Vi vil fortsætte med at udforske de forskellige typer sensorelementer, der bruges i forskellige produkter, hvordan de virker, og deres fordele og ulemper. Hvis du gerne vil have flere detaljer om, hvad der diskuteres her, kan du tjekke det relaterede indhold senere i denne vejledning. Hvis du er presset på tid, kan du også klikke her for at downloade detaljerne i denne guide Lufttrykssensor Produkt PDF -data.

For mere information om andre sensorteknologier, venligst Besøg vores Sensors -side.