Water level detection plays an important role in industry, agriculture and the residential sector. From water level monitoring in reservoirs and cisterns to the management of domestic water supply systems, accurate water level measurement is required. One of the most critical components of a water level detector is the sensor. Choosing the right pressure range not only has a direct impact on the accuracy of the measurement, but also on the reliability and service life of the device. Therefore, knowing how to select the right pressure range is essential to ensure the efficient operation of your system.

Let’s start understanding!

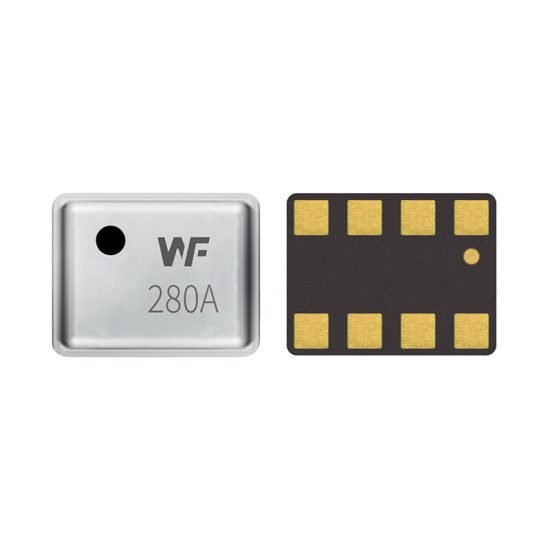

Katalog

BASIC STEPS IN BUILDING A WATER LEVEL DETECTOR

Constructing a complete and reliable water level detection system requires consideration of components such as sensors, signal acquisition modules, data processors and display modules. The following are the basic steps in building a water level detector:

Requirements analysis and design

Determine the target water level measurement range, environmental conditions and accuracy requirements. Preliminary selection of a suitable pressure sensor type based on the measurement depth.

Sensor Selection and Installation

Select a pressure sensor that meets the measurement range, signal output form and media compatibility. For example, the deep water environment select the high pressure range of the adiabatic pressure sensor. Installation should ensure good sealing and avoid air bubble interference.

Data acquisition and signal processing module construction

Use a single-chip microcomputer or PLC to collect the output signal of the sensor and convert it into water level data. For precision applications, a filtering algorithm can be added to reduce measurement noise.

Data output and display module

Build an LCD/LED display module to display water level information in real time. If it is an industrial scenario, a communication module such as RS485 or HART protocol can be integrated to achieve remote monitoring.

Calibration and testing

Use the standard liquid column height to calibrate the detector to ensure the accuracy of the measurement data. Perform multiple tests under different environmental conditions to verify the reliability of the equipment.

The working principle of the water level detector

- P=ρ×g×h

Where:

- 𝑃 denotes the static pressure of the liquid

- 𝜌 denotes the density of the liquid (usually taken as 1000 kg/m³ for water)

- 𝑔 denotes the acceleration of gravity (taken as 9.81 m/s²)

- ℎ denotes the height of the liquid column, i.e., the water level height

Since the static pressure is directly proportional to the water level height, the water level height can be calculated by measuring the pressure. Inside the sensor, the analog signal is usually converted into an electrical signal, which is then processed and output as water level information.

Considerations for designing a water level detector

Protection

level Water level detectors need to be in contact with water for a long time, so the sensor housing needs to have good waterproof and dustproof performance (IP68 protection level sensors are recommended).

Temperature Compensation

Large temperature differences in the water level environment may lead to measurement errors, so choose a sensor with temperature compensation to improve measurement accuracy.

Power management

Low-power design is critical for detectors that need to run for long periods of time, consider using low-power sensors and energy-saving power management modules.

Installation Location

Sensors need to be installed away from areas of turbulent water flow to minimize interference from air bubbles and pressure fluctuations. In addition, the sensor installation depth needs to be precise to ensure that its measurement range covers the maximum water level variation.

Signal interference shielding

Electromagnetic interference in industrial environments can affect measurement data, and it is recommended that shielded cables and filtering modules be used to improve the system’s immunity to interference.

Key Factors in Selecting Pressure Ranges

When selecting a pressure sensor for a water level detector, a number of factors need to be considered to ensure the accuracy of the measurement results and the reliability of the sensor.

1. Measuring range

The pressure range of the sensor should be selected based on the maximum possible water level height. For example, for a pool with a maximum water depth of 10 meters, the static pressure is approximately 98.1 kPa. Therefore, it is necessary to select a transducer with a pressure range of at least 100 kPa, in order to avoid measurement errors caused by over-range.

2. Environmental conditions

The sensor may need to work in different environmental conditions, including high temperature, low temperature, humid environment. It is necessary to ensure that the pressure range of the transducer can work properly under these environmental conditions.

3. Measurement accuracy requirements

If the measurement task requires a high degree of accuracy, e.g. fine water level monitoring in industrial control, it is necessary to select a high-precision pressure transducer and to ensure that its pressure range covers the required measurement range.

4. Media type

If the measurement medium is not pure water but a liquid containing impurities and corrosive components, you need to choose a sensor with a corrosion-resistant coating or diaphragm. In this case, the selection of the pressure range also needs to take into account the compatibility of the sensor material.

5. Signal output type

Different pressure ranges may correspond to different signal output types, such as 4-20mA, 0-10V or digital signal output. The signal compatibility of the system needs to be taken into account when selecting.

Different pressure ranges may correspond to different signal output types, such as 4-20mA, 0-10V or digital signal output. The signal compatibility of the system needs to be taken into account when selecting.

Scenarios for different air pressure sensor pressure ranges

- Low pressure range (0-50 kPa): for water level measurement in shallow areas, e.g. cisterns, farm irrigation systems.

- Medium pressure range (50-200 kPa): suitable for water level measurement in medium depth, e.g. industrial water tanks, sewage treatment systems.

- High pressure range (above 200 kPa): suitable for deep water measurement, e.g. reservoirs, hydroelectric power stations.

Technical Analysis

1. Gauge Pressure Sensors Application

Gauge pressure sensors measure pressure values relative to atmospheric pressure and are suitable for water level measurement in most open environments. These sensors are relatively inexpensive and simple to install and maintain.

2. Absolute Pressure Sensors

Absolutte tryksensorer measure pressure relative to a vacuum and are ideal for use in confined environments or where a high degree of accuracy is required, e.g. in deep water measurement systems.

3. Differential Pressure Sensors

Differential pressure sensors are used to measure the difference in pressure between two different points and are suitable for complex water level monitoring systems, such as industrial piping systems that require consideration of water level changes at multiple points.

Practical advice when selecting sensor

Define the measurement objective: Before selecting a sensor, define the measurement objective and the requirements for accuracy.

Consider future expansion needs: If there is a possible need to extend the measuring range, it is advisable to choose a sensor with a higher pressure range.

Focus on the sensor material: Make sure that the sensor material is resistant to the corrosive nature of the measurement medium.

Choose a supplier with a reliable brand name and service: A quality supplier will not only provide high-performance products, but also comprehensive technical support.

Konklusion

Choosing the right pressure range is critical to the performance of a water level detector. By comprehensively considering factors such as measurement range, environmental conditions, accuracy requirements and media type, measurement accuracy and system reliability can be effectively improved. In different application scenarios, a reasonable choice of gauge pressure, absolute pressure or differential pressure sensors can ensure the efficient operation of the water level monitoring system. We hope that the introduction of this article can provide a useful reference for your sensor selection.

Ovenstående introduktion ridser kun overfladen af anvendelserne af tryksensorteknologi. Vi vil fortsætte med at udforske de forskellige typer sensorelementer, der bruges i forskellige produkter, hvordan de virker, og deres fordele og ulemper. Hvis du gerne vil have flere detaljer om, hvad der diskuteres her, kan du tjekke det relaterede indhold senere i denne vejledning. Hvis du er presset på tid, kan du også klikke her for at downloade detaljerne i denne guide Lufttrykssensor Produkt PDF -data.

For mere information om andre sensorteknologier, venligst Besøg vores Sensors -side.