Katalog

Xiaomi air pumps utilize analog pressure sensors based on advanced MEMS technology, achieving high-precision pressure detection through silicon-silicon bonded structures. These sensors feature 0-700kPa detection range with internal trimming technology and optimized signal processing algorithms.

1. Core Technology Principles of MEMS Piezoresistive Sensors

Tekniske fordele ved siliciumsiliciumbundet struktur

MEMS piezoresistive pressure sensors employ silicon-silicon direct bonding technology to construct sensing structures, forming highly stable stress membranes and sealed cavities. The single-crystal silicon structure ensures excellent mechanical strength and thermal stability, while bonding processes guarantee internal vacuum environments, eliminating temperature drift and long-term stability issues.

Fysisk mekanisme for piezoresistiv effekt

Piezoresistive sensors operate based on silicon material’s piezoresistive effect. When mechanical stress is applied, silicon lattice structure undergoes micro-deformation, causing carrier mobility changes and resistance value variations. Xiaomi air pump sensors integrate four high-precision piezoresistive elements in maximum stress regions, forming Wheatstone bridge structures.

2. Manufacturing Process and Quality Control of Analog Sensors

Præcision Manufacturing Workflow

Sensor chips employ standard MEMS manufacturing processes including silicon wafer cleaning, oxide layer growth, photolithographic patterning, ion implantation doping, and high-temperature annealing. Critical silicon-silicon bonding processes occur at 1000°C in vacuum environments, ensuring atomic-level interface bonding. Precision thinning processes control silicon membrane thickness within 15±2μm ranges.

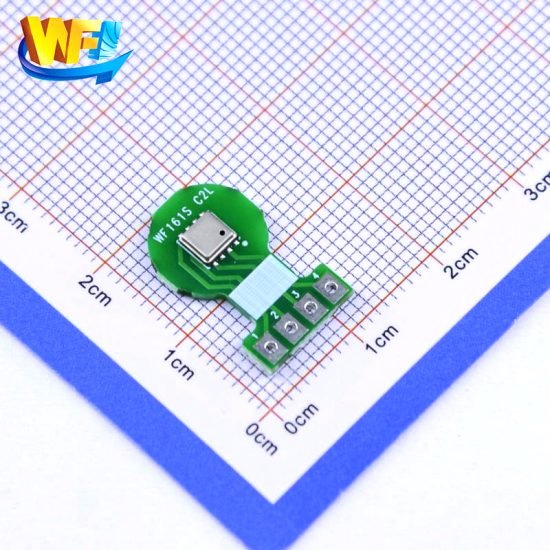

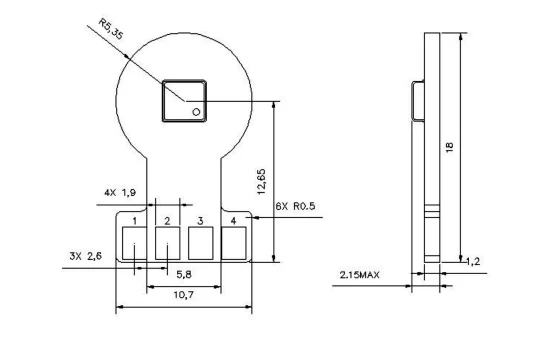

Implementering af LGA -emballage -teknologi

Sensors utilize PCB plus metal shell LGA packaging forms. Metal housings provide electromagnetic shielding and mechanical protection, while PCB substrates enable electrical connections and signal conditioning. Four solder pins correspond to positive/negative power supplies, signal output, and grounding, simplifying customer mounting processes.

3. Technical Implementation of Precision Measurement Performance

Kerne rolle for intern trimmingsteknologi

Xiaomi air pump sensors achieve precise calibration at four pressure points through internal trimming technology, including 0kPa, 200kPa, 500kPa, and 700kPa. Trimming processes use laser micro-adjustment resistor networks, precisely adjusting sensor zero-point offset and full-scale output, controlling nonlinear errors within 0.5%.

Temperaturkompensation og driftundertrykkelse

Sensors integrate temperature compensation circuits, employing polynomial temperature compensation algorithms to eliminate temperature effects on output signals. Through multi-point calibration across -20°C to +60°C ranges, temperature compensation coefficient tables are established, achieving accurate measurements across full temperature ranges.

4. Signal Processing and Algorithm Optimization

Analog signalprøvetagningsalgoritmer

Air pump solutions employ high-precision ADCs for analog signal sampling, with sampling frequencies set at 2kHz, ensuring accurate capture of rapid pressure changes. Signal processing algorithms include digital filtering, nonlinear correction, and anomaly detection, effectively filtering environmental noise and transient interference.

Anti-kondensationsdesignmekanismer

Sensors employ hydrophobic coatings and sealed structural designs, effectively preventing condensation formation in high-humidity environments. Metal housing thermal conduction characteristics ensure sensor temperatures remain consistent with environmental temperatures, avoiding condensation phenomena caused by temperature differences.

5. Industry Applications and Performance Comparison Analysis

Tekniske huller i markedskonkurrenter

Traditional air pumps commonly suffer from measurement inaccuracy issues, primarily due to sensor manufacturing errors, lack of effective calibration mechanisms, and inadequate signal processing algorithms. Xiaomi air pumps improve measurement errors from traditional products’ ±5% to ±1% through high-quality MEMS sensors and advanced signal processing technology.

Faktisk verifikation af applikationspræstation

In practical use, Xiaomi air pump analog pressure sensors demonstrate excellent repeatability and stability. After 1000 inflation-deflation cycle tests, sensor output repeatability errors remain below 0.2%, with long-term stability superior to 0.5%/year. This high-precision performance eliminates need for repeated tire pressure checks.

Konklusion

Analog sensor technology application significantly enhances Xiaomi air pump precision measurement performance. Through silicon-silicon bonded MEMS processes, precise internal trimming technology, optimized signal processing algorithms, and anti-condensation designs, ±1% high-precision measurement is achieved, solving traditional air pump measurement inaccuracy industry pain points.

Ovenstående introduktion ridser kun overfladen af anvendelserne af tryksensorteknologi. Vi vil fortsætte med at udforske de forskellige typer sensorelementer, der bruges i forskellige produkter, hvordan de virker, og deres fordele og ulemper. Hvis du gerne vil have flere detaljer om, hvad der diskuteres her, kan du tjekke det relaterede indhold senere i denne vejledning. Hvis du er presset på tid, kan du også klikke her for at downloade detaljerne i denne guide Lufttrykssensor Produkt PDF -data.

For mere information om andre sensorteknologier, venligst Besøg vores Sensors -side.