Sensor troubleshooting is an important part of ensuring stable and reliable system operation. With the increasing reliance on sensors in industrial automation, medical equipment, automotive electronics and other fields, sensor failure may have a significant impact on the function and safety of the entire system. Therefore, timely and accurate diagnosis and repair of sensor failures are critical to improving equipment reliability, extending service life, reducing maintenance costs, and ensuring system safety.

Common types of sensor failures include prolonged response time, reduced accuracy, zero drift, stability problems, and overload damage. These failures directly affect the measurement accuracy of the sensor and the operational efficiency of the system. Through troubleshooting techniques, problems can be quickly identified and repaired.

When carrying out sensor troubleshooting, it is necessary to firstly make preparations, including checking the installation environment (e.g. temperature and humidity, vibration, etc.), electrical environment (e.g. power stability and electromagnetic interference), mechanical environment (e.g. installation position and fixation measures), as well as confirming the sensor’s technical specifications and performance parameters. These preliminary preparations can provide basic data for subsequent diagnosis and ensure the effectiveness of fault diagnosis.

Common diagnostic methods include visual inspection, signal testing, oscilloscope analysis, and software analysis. These methods can help identify abnormal sensor appearance, signal distortion, performance fluctuations and other problems, and detect potential faults in a timely manner. Through replacement methods, environmental factor analysis, calibration and adjustment, etc., faults can be further diagnosed and repaired to ensure normal operation of the sensor.

Obsah

1. Overview of Sensor Fault Diagnosis

Common Types of Sensor Failures

1.1 Prolonged response time:

The response rate of the sensor to changes is slowed down, affecting the real-time performance of the system.

1.2. Reduced accuracy:

There is a discrepancy between the signal generated by the sensor and the actual measurement value, resulting in inaccurate measurement results.

1.3. Zero drift:

In the absence of an input signal, the value of the signal output from the sensor fluctuates, usually due to fluctuations in temperature, humidity, power supply voltage or natural aging of the components.

1.4. Stability problems:

After a long period of operation, the performance of the sensor will gradually deteriorate, resulting in instability of the output signal.

1.5 Reduced sensitivity:

The sensor’s response to the input signal is weakened, resulting in a reduction in the amplitude of the output signal.

1.6. Overload Damage:

The sensor has been subjected to an input that exceeds its design specifications, resulting in permanent damage.

1.7. Electrical Failure:

Problems involving short circuits, broken circuits, poor contacts, etc., may cause the sensor to fail to function properly or to emit false signals.

1.8. Mechanical failure:

Damage to the mechanical components of the sensor, including but not limited to bearing wear, poor sealing performance, etc.

1.9. Environmental adaptation problems:

Sensor performance is degraded when exposed to extreme environmental conditions such as temperature, humidity, pressure, etc.

1.10. Signal interference:

External electromagnetic interference causes distortion of the sensor signal.

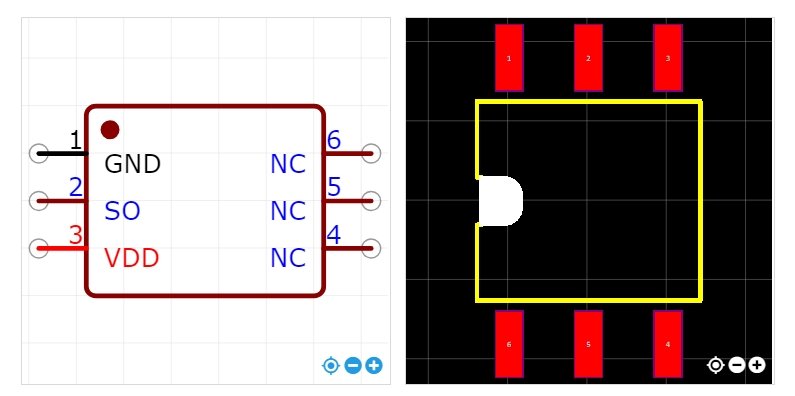

1.11. Incorrect soldering

Solder is not sufficiently melted or does not completely cover the contact points during soldering, resulting in poor contact. Sensors that are soldered with false soldering may result in unstable signal transmission or even a complete loss of sensing capability. Resulting in unstable sensor output signals or complete inability to work. Improper soldering may result in unstable or distorted sensor output signals, thus affecting measurement accuracy.

2. Importance of sensor troubleshooting

2.1. Increased safety:

In safety-critical applications such as automobiles and medical equipment, sensor failures can have serious consequences. Therefore, troubleshooting is essential to ensure that these systems can operate safely.

2.2 Ensuring system reliability:

With the help of diagnostic techniques, problems with sensors can be quickly identified and corrected, thus preventing overall system failure due to sensor malfunction.

2.3. Reduce downtime:

Quickly and accurately diagnosing sensor failures reduces equipment downtime, which in turn improves production efficiency.

2.4. Improve product quality:

Sensor failures can lead to product quality problems, including inaccurate measurements or poor control. The application of troubleshooting techniques helps to ensure consistent product quality.

2.5. Reduce maintenance costs:

By implementing preventive maintenance and troubleshooting strategies, the frequency of sensor replacement can be significantly reduced, thereby reducing maintenance costs.

2.6. Extend equipment life:

Regular fault detection and maintenance can effectively extend the life of sensors and related equipment.

2.7. Optimise resource allocation:

Troubleshooting techniques help identify sensors at higher risk of failure, thereby optimising the allocation of maintenance resources.

2.8. Support decision-making:

The data and information provided by troubleshooting can support management in making decisions about equipment maintenance and upgrades.

2.9. Improve system adaptability and intelligence:

In the field of intelligent systems, fault diagnosis technology is the core of the realisation of adaptive control and self-repair functions.

2.10. Meeting regulatory requirements:

In specific areas, such as the aerospace and automation industries, sensor fault diagnosis constitutes a necessary condition for meeting safety regulations and standards.

2. Preparation for sensor troubleshooting

Check the installation environment of the sensor

1. Physical environment check

(1) Cleanliness: Ensure that the periphery of the sensor is free from dust, dirt, and other potential contaminants that could adversely affect the performance of the sensor.

(2) Vibration: Check for severe mechanical vibration, which may damage the sensor or cause inaccurate readings.

(3) Temperature and humidity: Check whether the current ambient temperature and humidity are within the operating range of the sensor. Extreme temperature and humidity conditions may adversely affect the stability and service life of the sensor.

2. Electrical Environment Inspection

(1) Electromagnetic interference: Check for potential sources of electromagnetic interference, such as large electric motors or high-voltage power lines, which may affect sensor signal transmission.

(2) Power stability: Ensure that the sensors power supply remains stable, as voltage fluctuations may adversely affect the sensors performance.

3. Mechanical Environment Inspection

(1) Installation position: Check whether the sensor has been correctly installed in the specified position, because improper installation position may cause reading errors or cause damage to the sensor.

(2) Fixing and supporting measures: Ensure that the sensors fixing and supporting structure is firm and reliable to effectively prevent mechanical vibration or impact caused by the sensor displacement phenomenon.

Confirmation of sensor specifications and parameters

1. Check the technical documents

(1) Model and specifications: Confirm that the model and specifications of the sensor meet the requirements of the application.

(2) Power requirements: Confirm the power supply voltage and current requirements of the sensor, and ensure that it is consistent with the power supply capacity provided by the system.

2. Confirmation of performance parameters

(1) Measurement range: Verify that the measurement range of the sensor includes all the values that may be involved in the actual application scenario.

(2) Accuracy and resolution: Verify that the accuracy and resolution of the sensor can meet the accuracy standards required by the application.

(3) Response time: Know the response time of the sensor to ensure that it can meet the requirements of real-time monitoring.

3. Interface and Compatibility

(1) Signal type: Make sure the type of signal output from the sensor is consistent with the type of input required by the system.

(2) Protocol: If the sensor adopts digital communication, please make sure that its protocol is consistent with the interface of the system.

3. Sensor Fault Diagnosis Methods

3.1 Visual Inspection

3.1.1. Check the sensor for any visual anomalies.

(1) Check the sensor housing for cracks, deformation, or any signs of damage.

(2) Verify that the sensor’s indicator lights are in proper operating condition, including whether they are illuminated or flashing as expected.

(3) Verify that sensor labels and markings are legible so that model and specification information can be accurately confirmed.

3.1.2 Check the integrity of the connecting wires.

(1) All wires are carefully inspected to ensure that they are securely connected and not loose or disconnected in any way.

(2) The wires are thoroughly inspected for signs of abrasion, breakage or other forms of damage to the surface.

(3) Connectors are kept in clean condition without any corrosion or contamination.

3.2 Signal Test

3.2.1. Use a multi-meter to test the sensor output signal.

(1) Use a multi-meter to measure the voltage or current output of the sensor to verify that it is within the preset range.

(2) The continuity and stability of the signal is checked to identify any unusual fluctuations.

3.3 Analysing Signal Waveforms with an Oscilloscope

(1) The waveform of the signal is observed using oscilloscope equipment with the aim of identifying any distortion or anomalies that may exist.

(2) The frequency, amplitude and phase of the waveforms are thoroughly analysed to confirm that they are consistent with the expected settings.

3.4 Software Analysis

3.4.1. Using professional software to read sensor data

(1) Use software tools that are compatible with the sensor to read real-time data and historical records.

(2) Verify data consistency and trends to identify any unusual patterns. .

3.4.2. Analysing Troubleshooting Reports Provided by Software

(1) Troubleshooting reports generated by professional software analysis tools are used to accurately identify possible problems.

(2) Perform corresponding troubleshooting and repair work based on the recommendations made in the report.

3.5 Replacement Method

3.5.1. Basic Principle of the Replacement Method

(1) Accurately identify the faulty component by replacing the suspected faulty sensor.

(2) The replacement method is used to find and locate the problem, especially in configurations with multiple sensors.

3.5.2. Steps for the Replacement Method in Practice

(1) Ensure that the power supply is completely switched off before performing the replacement operation to ensure safe operation.

(2) Replace the suspected faulty sensor with one that is known to be in good condition.

(3) Then restart the system and conduct a test to verify that the fault has been successfully removed.

3.6 Analysis of Environmental Factors

3.6.1. Analyse the effect of temperature and humidity on the sensors.

(1) Check that the sensor is operating under the specified environmental conditions.

(2) Verify that there are no extreme fluctuations in temperature or humidity that could affect the performance of the sensor.

3.6.2. Explore the effects of electromagnetic interference on the sensor.

(1) Identify and analyse potential sources of electromagnetic interference in the ambient environment and assess the specific effects they may have on the sensor signal.

(2) Adopt appropriate shielding and isolation measures to effectively mitigate the effects of such interference.

3.7 Calibration and Adjustment

3.7.1. Sensor calibration basic steps

(1) Follow the calibration procedures and specifications provided by the manufacturer.

(2) Adopt the calibration device to adjust the sensor output to ensure its accuracy.

3.7.2. Adjust the sensor to restore its normal function.

(1) Based on the calibration feedback, make appropriate adjustments to the sensor position, angle and other relevant parameters.

(2) Re-test the sensor to ensure that it is restored to its normal function and performance.

Závěr

Sensor troubleshooting is a critical part of ensuring the reliability and performance of a sensor system. Common types of sensor failures include extended response times, reduced accuracy, zero drift, stability issues, overload damage, etc. These problems not only affect system stability, but can also jeopardise safety and productivity. Effective troubleshooting not only enables timely detection and repair of faults, but also improves system safety, reliability and product quality.

In the process of sensor troubleshooting, preliminary preparatory work is crucial, including checking the installation, electrical and mechanical environments of the sensors, and confirming the sensor specifications and performance parameters. In terms of diagnostic methods, visual inspection, signal testing, oscilloscope analysis and software analysis are commonly used techniques, while methods such as substitution, environmental factor analysis and calibration adjustment also play an important role in fault diagnosis.

Through these methods, sensor faults can be located quickly and efficiently, ensuring continued stable system operation and extending the life of the equipment. Therefore, sensor fault diagnosis is not only a technical process, but also the basis for enhancing system intelligence and autonomous repair capability.

An outstanding share! I have just forwarded this onto a

coworker who has been conducting a little research on this.

And he actually bought me lunch simply because I found it for him…

lol. So let me reword this…. Thanks for the meal!!

But yeah, thanx for spending some time to talk

about this issue here on your site.