- Podle WFsensors

This scheme focuses on the absolute pressure sensor — high-resolution, stable atmospheric pressure data acquisition approach, looking at how to get continuously trustworthy pressure readings in real-world settings. It tackles five main interference sources: temperature shifts, mechanical vibration, electromagnetic disturbance, unstable power supply and long-term drift. The plan covers everything from sensor selection to signal conditioning, power management, sampling strategy, algorithmic compensation and system-level cooperation. The aim is practical engineering methods that keep sensors delivering high-resolution, low-noise, stable pressure data over time — supporting automation, environmental monitoring, smart devices and lab measurement.

Katalog

1. Measurement Basics and Sources of Accuracy for Pressure Sensors

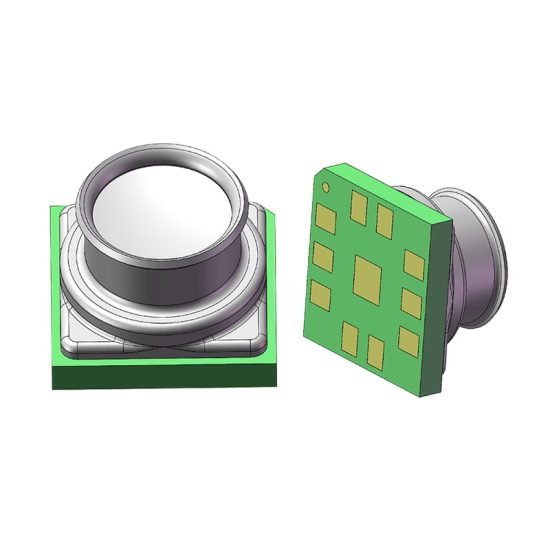

Good pressure data starts with a clear grasp of measurement mechanisms and how accuracy is built up. An absolute pressure sensor uses a sensing membrane that responds to external pressure and turns that into an electrical signal. That signal is then amplified and converted into readable data. Final accuracy is not just about resolution — linearity, repeatability, hysteresis and long-term stability all matter. When choosing a sensor, match the range and target accuracy. Pay attention to both short-term noise and long-term drift. A high-resolution device on its own won’t keep readings trustworthy over time unless the whole system fights disturbance. So, design with “long-term trust” as the main goal — from materials and packaging to circuits and algorithms.

1.1 Sensing element and signal chain

The sensing element’s geometry and material set the raw signal’s quality. Pick a membrane material and a mature fabrication process that lower zero drift and non-linearity. The first stage amplifier and filter must be low-noise and match the signal bandwidth to your sampling rate, avoiding added distortion or phase lag.

2. Main Interference Sources That Affect Stable Pressure Acquisition

In real use, environment and system factors create varied interference. Temperature changes alter both sensor and electronics characteristics, causing zero shifts and sensitivity changes. Mechanical vibration adds transient noise and can cause structural fatigue over time. Electromagnetic interference (EMI) can ride on microvolt-level signals, and unstable power supplies shift amplifier operating points. Without drift detection and correction, long-term slow drift will erode data trust. Spotting and mitigating these interferences is the heart of a stable acquisition plan.

2.1 How ambient temperature affects readings and how to spot it

Temperature drift is one of the most common error sources. By measuring temperature alongside pressure and using a dynamic compensation model, you can correct temperature-related errors in real time. Hardware measures such as thermal isolation and even-heat design also help to reduce the effect of temperature swings on outputs, improving long-term stability.

3. Hardware Design Strategies for High-Precision, Stable Pressure

Hardware design must be systematic: sensor choice, front-end amplification, analogue filtering, ADC and power management are all key. Choose sensors based on real operating range and accuracy targets — don’t chase headline resolution alone. The front end needs low-noise amplification and sensible filtering. PCB layout must minimise parasitics and coupling. Pick an ADC with sufficient resolution and linearity, and set sampling so it matches the dynamics of pressure changes — avoid under- or over-sampling that leads to odd readings or wasted power. Voltage regulation and isolation are essential to cut supply noise.

3.1 Signal conditioning and power stabilisation design

Amplifying microvolt signals demands very low input noise and good common-mode rejection. Choose the op-amps carefully and use PCB practices like split grounds, shielding and decoupling to reduce noise injection. Power sections should include filters to remove ripple and local regulators and decouplers at critical points to give the analogue front end a stable supply.

4. Software and Algorithm Support for Stable Pressure Acquisition

Algorithms are the soul of long-term trustworthy data. To tackle random noise and short disturbances, use time-domain filters and adaptive filters to smooth readings. For long-term drift, implement trend analysis and correction based on historical data. Temperature compensation models must be updated dynamically to cope with changing conditions — static correction won’t cut it in complex environments. Anomaly detection and fault-tolerant logic make sure spikes are flagged or excluded so they don’t corrupt higher-level decisions.

4.1 Dynamic compensation and drift detection

Keep recording temperature and outputs, and run trend analysis to spot slow drift. When drift is detected, trigger recalibration or maintenance alerts. Use online-updateable compensation parameters so the model adapts on the fly. Combine statistical techniques and rule engines for anomaly detection to automatically filter out suspect samples.

5. System-Level Co-Design to Improve Acquisition Stability

Stable acquisition is a systems problem — the sensor is only one piece. Mount sensors away from direct airflow shocks, local heat sources and vibration hotspots. Multi-point sampling with data fusion reduces sensitivity to single-point faults and boosts overall robustness. Choose communications with error-checking and retry logic so data isn’t corrupted in transit. System validation is crucial: include on-site calibration, long-term regression checks and maintenance alerts.

5.1 Mounting layout and multi-point fusion strategy

Good installation cuts the impact of external disturbances. Using multiple sensors and weighted fusion or filtering can raise reliability without huge complexity. For communication, add checksums and retransmit strategies so every step from sensor to backend is traceable and verifiable.

Implementation Checklist and Engineering Handover Points

Any design must be turned into reliable engineering practice. Before delivery, complete sensor factory calibration, system-level tests, thermal chamber runs and vibration tests. On site, perform initial calibration, set up long-term drift monitoring and enable remote updates. Keep clear test logs and maintenance prompts so issues can be found and fixed quickly. Regularly check acquisition chains and power quality to spot risks early and extend stable operation time.

Závěr

To deliver an absolute pressure sensor — high-resolution, stable atmospheric pressure data acquisition scheme, you must think systemically: components, circuits, sampling strategy, algorithmic compensation and practical deployment all matter. A high-resolution sensor alone won’t produce long-term trustworthy data. Only by integrating sensible sensor choice, careful layout, low-noise circuit design, dynamic compensation and system-level cooperation can you maintain reliable pressure readings in messy real-world conditions. This plan lays out practical engineering steps and verification methods to help obtain sustained, accurate pressure data for automation, environmental monitoring and smart devices.

Výše uvedený úvod pouze poškrábe povrch aplikací technologie tlakových senzorů. Budeme pokračovat ve zkoumání různých typů senzorových prvků používaných v různých produktech, jejich fungování a jejich výhod a nevýhod. Pokud byste chtěli více podrobností o tom, o čem se zde diskutuje, můžete se podívat na související obsah později v této příručce. Pokud vás tlačí čas, můžete také kliknout sem a stáhnout si podrobnosti o těchto příručkách Data produktu PDF na tlak vzduchu.

Pro více informací o dalších senzorových technologiích prosím Navštivte naši stránku Sensors.