ক্যাটালগ

1. Corrosive Environments and Application Background

1.1 Impact of Corrosive Media

Air pressure sensors play a vital role in countless industries—from automotive systems to medical devices. When these sensors deliver stable and accurate readings day after day, it makes all the difference between efficient operations and critical errors. In this article, we explore air pressure sensor stability in detail.

1.2 Real-World Application Examples

From industrial control systems to automotive safety measures and personal wearables, the demand for sensors that maintain high precision in aggressive environments is growing. In these applications, sensors must not only measure pressure and temperature reliably but also resist the damaging effects of corrosive agents.

2. Overview of MEMS Sensor Technology

2.1 Key Features of MEMS Design

MEMS technology enables the miniaturization and high integration of sensor components. Typically, the sensor incorporates a silicon diaphragm with strain gauges placed along its edge. When subjected to pressure, the diaphragm deflects similarly to a trampoline, causing a change in the strain gauge resistance that can be measured.

2.2 Signal Conditioning and Digital Conversion

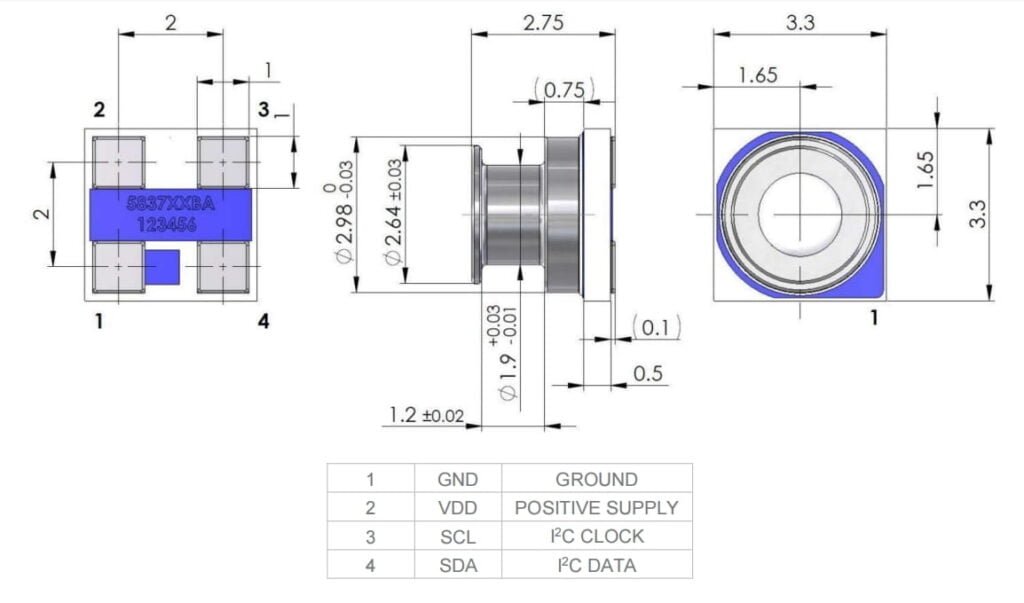

Within the sensor, integrated CMOS ASIC circuits compensate for temperature drift and other errors. The conditioned analog signal is then amplified, digitized, and transmitted via standard I2C or SPI interfaces, ensuring precise and reliable communication with a microprocessor.

3. Applications in Corrosive Environments

3.1 Industrial and Automotive Sectors

In industries like manufacturing and automotive safety systems, sensors are often used in environments that include corrosive gases or liquids. Besides delivering accurate measurements, these sensors must resist chemical damage over time. For example, certain volatile halogenated compounds from organic polymers can cause irreversible changes on MEMS surfaces.

3.2 Wearable Devices in Harsh Conditions

In the realm of sports watches and diving instruments, sensors must operate in chlorine-rich water. Advanced packaging techniques prevent corrosive substances from infiltrating sensitive sensor components, ensuring long-term, stable performance.

4. Operating Principles of MEMS Pressure Sensors

4.1 Strain Gauge Mechanism and Mechanical Response

When external pressure is applied, the silicon diaphragm deforms, and strain gauges located along its periphery alter their resistance. By employing a Wheatstone bridge configuration, the sensor boosts signal strength and minimizes noise, delivering a clean baseline for further processing.

4.2 Signal Offsets and Corrosion Effects

Ideally, the differential output voltage should read 0V when no pressure is applied. Any offset typically signals that corrosion-induced changes in the sensor elements are at play, necessitating design considerations to maintain reliability.

5. Packaging Strategies and Environmental Protection

5.1 The Role of Robust Packaging

Effective packaging ensures that the sensor is both in contact with the medium it monitors and adequately isolated from harmful substances. In harsh settings, the design must integrate compact yet robust connections to protect sensitive components against corrosive chemicals.

5.2 Material Selection and Assembly Techniques

To counteract attacks from aggressive oxidizers (such as fluorine, chlorine, bromine, and iodine), manufacturers choose corrosion-resistant materials and advanced processes. Protective coatings and precision assembly methods are implemented to maximize sensor durability.

6. Testing and Performance Verification in Harsh Conditions

6.1 Accelerated Laboratory Testing

Sensors are subjected to saltwater, chlorine water, and even diiodomethane exposure in controlled environments to monitor signal drift. The results indicate that with targeted design, the sensors exhibit only minor drifts—effects that can be largely attributed to ambient humidity rather than chemical degradation.

6.2 Field Validation

Beyond lab tests, real-world experiments are essential. Extended field trials under actual operating conditions confirm that these sensors consistently provide accurate and stable data, reinforcing confidence in their long-term application.

উপসংহার

A thorough review of the sensor’s internal design, operating principles, protective packaging, and rigorous testing demonstrates that modern MEMS pressure and temperature sensors deliver both precision and durability, even in corrosive environments. This robust approach underpins the reliability of systems across various sectors, ensuring devices perform consistently over time.

উপরের ভূমিকাটি শুধুমাত্র চাপ সেন্সর প্রযুক্তির প্রয়োগের পৃষ্ঠকে স্ক্র্যাচ করে। আমরা বিভিন্ন পণ্যে ব্যবহৃত বিভিন্ন ধরণের সেন্সর উপাদান, তারা কীভাবে কাজ করে এবং তাদের সুবিধা এবং অসুবিধাগুলি অন্বেষণ করতে থাকব। এখানে কি আলোচনা করা হয়েছে সে সম্পর্কে আপনি যদি আরও বিশদ জানতে চান, তাহলে আপনি এই নির্দেশিকায় পরে সংশ্লিষ্ট বিষয়বস্তু দেখতে পারেন। আপনি যদি সময়ের জন্য চাপ দেন তবে আপনি এই গাইডের বিশদ বিবরণ ডাউনলোড করতে এখানে ক্লিক করতে পারেন বায়ুচাপ সেন্সর পণ্য পিডিএফ ডেটা.

অন্যান্য সেন্সর প্রযুক্তি সম্পর্কে আরও তথ্যের জন্য, অনুগ্রহ করে আমাদের সেন্সর পৃষ্ঠা দেখুন.