- দ্বারা WFsensors

Invasive pressure sensors do the heavy lifting of turning blood pressure into monitorable data. With good sensitivity and tidy linear output, they’re now a key hardware item in invasive monitoring. This write-up covers the sensor itself, packaging, signal conditioning and system compatibility, offering practical engineering pointers to help engineers and technical leads make decisions on parts and integration.

ক্যাটালগ

1. invasive blood-pressure sensing and real-time clinical feedback

An invasive pressure sensor sits at the front line of the monitoring chain and directly affects how trustworthy the clinic’s data is. Engineering has to balance reliability, manufacturability and bedside usability. Whether you’re measuring aortic, venous or pulmonary pressures, the sensor must produce a stable, low-drift electrical signal from tiny pressure differences so you get continuous waveforms and numbers you can rely on. Interface agreements between suppliers and hospitals, the pairing of disposable consumables and how the monitor conditions the signal — all of that shapes the value of the monitoring system. Choosing the right invasive pressure sensor sharpens care for critically ill patients: it gives clinicians quicker, clearer insight so they can act faster and smarter.

Design starting points and clinical needs

Designers must begin with the use case. In the ICU or operating theatre the sensor sees temperature shifts and real fluid coupling issues and mustn’t add phase lag or damp the signal along the fluid line. Packaging needs to preserve the sensing element’s linear response when pressure is transmitted through saline, while also physically protecting the element from damage during assembly. From a supply and procurement angle, batch consistency and traceability are non-negotiable for regulatory compliance and hospital purchasing.

2. piezoresistive measurement and materials design

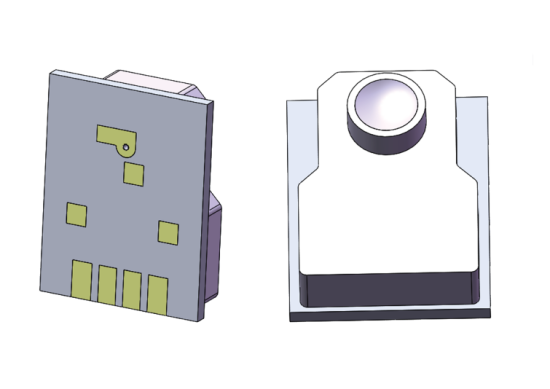

Most modern invasive pressure sensors use silicon piezoresistive chips: the sensing element’s resistance changes under stress, and a bridge plus conditioning circuit turns that into a voltage. Smart ceramic substrate and plastic cap design protect the chip while keeping efficient pressure coupling to the fluid column. Medical-grade gel sits between chip and fluid — it protects the chip face and keeps pressure transmission steady. On-board compensation and calibration networks handle temperature drift and zero stabilisation — these engineering bits are what give you long-term stability in the clinic.

Role of ceramic substrates and medical gel

The ceramic substrate gives mechanical support, good insulation and biocompatibility, letting you pack things tightly. Medical gel cushions mechanical shocks, fills microgaps and evens out pressure transfer. Packaging also has to account for reliable electrical contacts and the cost control needed for disposables, so mass production hits performance targets without blowing the per-unit cost. Good material choices and packaging processes cut assembly losses, improve yields and make the product more robust in storage and transit.

3. sensitivity, linearity and overload protection

Based on WF series engineering practice, piezoresistive invasive blood-pressure sensors show clear advantages in sensitivity, linearity and overload tolerance. Typical specs: pressure range −50 to 300 mmHg; operating temp +15°C to +40°C; sensitivity 5 μV/V/mmHg; input impedance 1200–3200 Ω; output impedance 285–315 Ω. Those figures give high-resolution electrical signals across the clinical range and built-in mechanical/electrical protection against brief overloads or sudden pressure spikes — avoiding sensor damage and distorted readings.

Comparing to strain-gauge sensors

Compared with traditional strain-gauge devices, piezoresistive chips often win on size, production consistency and linear output. Strain gauges might be tougher in some extreme conditions, but piezoresistive chips are easier to integrate with modern electronics and scale in volume manufacturing. If your system needs high resolution and continuous dynamic sampling, piezoresistive is usually the smarter engineering route.

4. single-use sensors and monitor compatibility

A single-use invasive blood-pressure sensor typically bundles a fluid channel, valves, the sensing unit and the electrical connector. The invasive pressure sensor is the core and talks to the monitor via a disposable cable or socket. Good compatibility design standardises electrical interfaces, matches signal amplitude and impedance, and makes it simple to plug into a monitor’s conditioning stage. Tight system integration cuts assembly steps, reduces operator errors and improves clinical workflow.

Interface needs for infusion pumps and dialysis kit

In infusion pumps and haemodialysis systems, pressure feedback often drives closed-loop control or alarm triggers. Sensor response time, bandwidth and immunity to interference directly influence control performance. Connectors should be easy to fit and swap, disposables should be manageable from a waste/replacement standpoint, and supply stability is crucial — hospitals need reliable sourcing so therapy isn’t interrupted.

5. Clinical deployment and workflow

Deploy with simplicity, safety and repeatability in mind. Single-use invasive sensors remove cleaning and disinfection steps, cutting cross-infection risk and trimming handling overhead during catheter setup, continuous monitoring and routine care. Clear installation guides, quick self-checks and consistent monitor interfaces reduce user mistakes and make alarms more dependable. Vendors who test electrical performance and perform zero calibration on every batch seriously shorten clinic prep time.

Infection control and the value of disposables

One big plus of single-use sensors is removing cleaning and sterilisation work, thereby lowering cross-infection risk. Disposables also make usage tracking easier for quality management. Engineers should balance disposable cost and environmental impact to strike the right compromise between clinical safety and operating expense.

উপসংহার

By combining piezoresistive chips, ceramic substrates, medical gel and tight packaging, invasive pressure sensors power a range of monitoring devices — improving measurement accuracy, response speed and system reliability. When picking and integrating sensors, engineers should focus on pressure range, sensitivity, input/output impedance, temperature drift and batch consistency. For device makers, working with mature suppliers and insisting on strict incoming inspection and factory calibration are key to reliable clinical performance. A compliant, well-engineered sensor turns invasive monitoring into data clinicians can actually trust.

উপরের ভূমিকাটি শুধুমাত্র চাপ সেন্সর প্রযুক্তির প্রয়োগের পৃষ্ঠকে স্ক্র্যাচ করে। আমরা বিভিন্ন পণ্যে ব্যবহৃত বিভিন্ন ধরণের সেন্সর উপাদান, তারা কীভাবে কাজ করে এবং তাদের সুবিধা এবং অসুবিধাগুলি অন্বেষণ করতে থাকব। এখানে কি আলোচনা করা হয়েছে সে সম্পর্কে আপনি যদি আরও বিশদ জানতে চান, তাহলে আপনি এই নির্দেশিকায় পরে সংশ্লিষ্ট বিষয়বস্তু দেখতে পারেন। আপনি যদি সময়ের জন্য চাপ দেন তবে আপনি এই গাইডের বিশদ বিবরণ ডাউনলোড করতে এখানে ক্লিক করতে পারেন বায়ুচাপ সেন্সর পণ্য পিডিএফ ডেটা.

অন্যান্য সেন্সর প্রযুক্তি সম্পর্কে আরও তথ্যের জন্য, অনুগ্রহ করে আমাদের সেন্সর পৃষ্ঠা দেখুন.