High and low temperature test is used to determine the adaptability of the product in the high and low temperature climate environment conditions of storage, transportation, use of the method. In the automotive electronics, industrial control of new energy and other industries, for the use of the chip has strict requirements, the use of the chip in the harsh environment can work properly, how reliable, has become an important concern. High and low temperature test can simulate the extreme high and low temperature environment, in order to test and evaluate the performance, reliability and adaptability of the chip in different temperature conditions.

Recently, many customers have inquired whether the performance of our MEMS pressure sensors meets the requirements at the extreme temperature of -40℃. So this test selected one of our products, which are WF183DE absolute pressure sensors.

ক্যাটালগ

Let’s start understanding!

MEMS Pressure Sensors at -40°C

If you use MEMS pressure sensors in extreme environments, or are just curious about their ability to survive the “frozen hell” of -40°C, then this article is for you. We’ll skip the fancy marketing jargon and get right to the point: how do these sensors perform in such extreme environments? Do they go on strike? Do they make mistakes? Or are they as stable as they can be?

The Impact of Low Temperatures on MEMS Pressure Sensors

Let’s start with the conclusion: MEMS pressure sensors can operate at -40°C, but how well they perform depends on the design, materials and compensation mechanisms. Temperature affects the accuracy, responsiveness and long-term stability of the sensor. In particular, low temperatures can lead to mechanical stress changes in the silicon material, aging of the bonding layer, shrinkage of the encapsulation material, and even fluctuations in impedance within the circuit. These factors can lead to sensor drift, increased linearity errors, and even complete failure.

At the heart of MEMS sensors are silicon-based resonant or piezoresistive elements. While silicon offers good temperature stability, the material’s Young’s modulus (Young’s modulus) changes slightly in extreme cold, affecting the sensitivity of pressure measurements. In addition, temperature changes can affect the stability of the excitation voltage, which can lead to data fluctuations.

Physical Challenges of MEMS Pressure Sensors in Cold Temperature Environments

At the heart of MEMS (microelectromechanical systems) pressure sensors are silicon-based materials that sense pressure through piezoresistive effects or changes in capacitance. But at -40°C, everything becomes more complicated. Let’s take a look at the three main challenges posed by low temperatures:

Material Shrinkage and Stress Deformation

Low temperatures cause changes in the coefficient of thermal expansion of the silicon material, and the matching of the package material to the chip may produce microscopic stress changes. This can lead to drift, loss of sensitivity, and even, in extreme cases, outright sensor failure.

Low Temperature Drift of Electronic Components

The ASIC (Application Specific Integrated Circuit) inside the sensor can be affected by low temperatures, resulting in gain changes, unstable signal processing, and even bias errors. You may find that a sensor that reads accurately at room temperature begins to babble at -40°C.

Package Hermeticity and Moisture Condensation

Low temperatures may cause the encapsulation material to shrink and seal. If moisture seeps inside the sensor, tiny ice crystals may form at very low temperatures, further affecting measurement accuracy and even damaging sensitive components.

How to optimize the performance of MEMS sensors at extreme low temperatures?

Excellent sensor manufacturers have long considered the extreme temperature problem, WF183DE Absolute Pressure Sensor and adopted a series of solutions to ensure that the sensor can still work stably at -40℃:

✅ Temperature compensation technology

Modern MEMS pressure sensors are usually equipped with temperature compensation algorithms, WF183DE which adjust the pressure reading in real time through additional temperature sensors to minimize the errors caused by temperature changes.

✅ Specialized Package Design

WF183DE packaging materials that are more resistant to low temperatures, such as metal or ceramic packages, are used instead of plastic housings that are susceptible to temperature. This dramatically improves long-term stability.

✅ Optimized electronic circuitry

WF183DE Electronic components with better low-temperature performance are selected and specially calibrated for temperature so that they can maintain accurate measurements even at -40°C.

✅ Extreme environmental testing

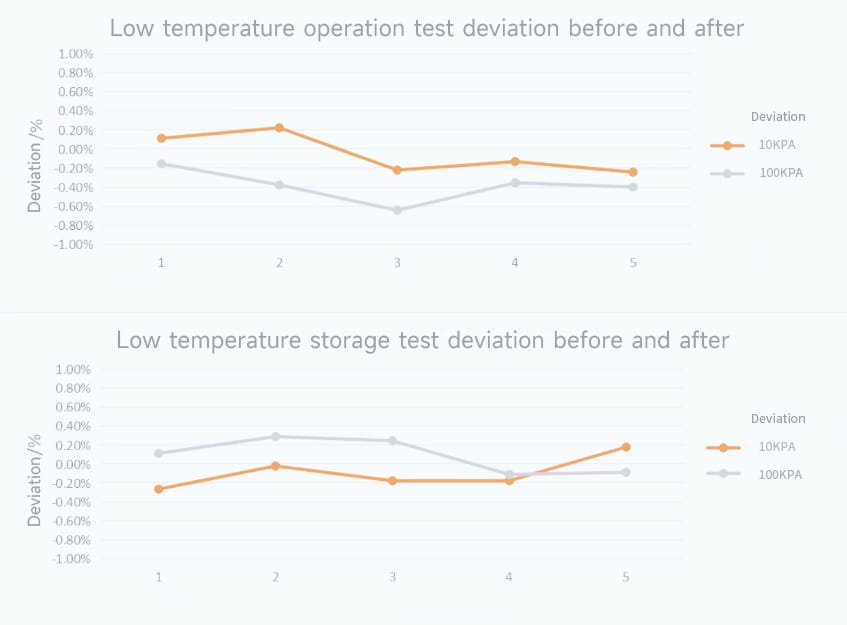

WF183DE pressure sensors are subjected to environmental warehouse testing to simulate extreme conditions at -40°C or even lower temperatures to ensure that the sensors will not fall off in real applications.

Real-World Applications: Are MEMS Pressure Sensors Reliable in Low Temperature Environments?

1. Automotive industry

MEMS pressure sensors are widely used in modern automobiles for applications such as tire pressure monitoring (TPMS) systems and engine intake pressure monitoring. Winter temperatures in many regions can easily fall below -40°C, but these sensors still work properly.

2. Aerospace

Aircraft flying at high altitude, the external ambient temperature is often as low as -50 ℃ or even colder. Aerospace-grade MEMS pressure sensors are rigorously tested at low temperatures to ensure accurate data.

3. Industrial Automation

MEMS sensors are indispensable for applications such as pipeline pressure monitoring and hydraulic system control in cold climates. The key is to choose the right product, industrial-grade sensors tend to remain stable in extreme temperatures.

So, is the WF183DE pressure sensor OK at -40°C or not?

The conclusion is simple: as long as the right sensors are selected, they are perfectly fine at -40°C! Of course, not all MEMS pressure sensors can work stably in extreme environments. If you buy a cheap consumer-grade product, it’s almost a given that something will go wrong at low temperatures. But if you choose the WF183DE sensors, they are rigorously tested at low temperatures and equipped with a variety of optimized technologies to still measure accurately at -40℃.

Final Advice

- Pay attention to the operating temperature range of the sensor when selecting (-40°C or lower must be explicitly supported)

- Check if the product is temperature compensated and low temperature tested

- Choose reliable brands and suppliers to avoid low quality products

উপসংহার

Can MEMS pressure sensors operate at -40°C? Of course they can, but only if they are professionally designed with temperature compensation, low-temperature resistant packaging, and high-precision signal processing. Ordinary consumer-grade MEMS sensors on the market can be inaccurate or even damaged in extreme cold environments, but the WF183DE sensor is fully up to the challenge.

If you’re looking for MEMS pressure sensors that can perform well in extreme temperatures, remember to focus on models with temperature compensation, package optimization, and signal enhancement technology. Otherwise, you may end up with a bunch of “Unwilling to work” sensors in -40°C environments instead of accurate data.

Next time you’re using a MEMS pressure sensor in a -40 degree environment, you know what to choose! If you have any questions or experiences to share, feel free to leave a comment and we’ll discuss it together! 🚀

উপরের ভূমিকাটি শুধুমাত্র চাপ সেন্সর প্রযুক্তির প্রয়োগের পৃষ্ঠকে স্ক্র্যাচ করে। আমরা বিভিন্ন পণ্যে ব্যবহৃত বিভিন্ন ধরণের সেন্সর উপাদান, তারা কীভাবে কাজ করে এবং তাদের সুবিধা এবং অসুবিধাগুলি অন্বেষণ করতে থাকব। এখানে কি আলোচনা করা হয়েছে সে সম্পর্কে আপনি যদি আরও বিশদ জানতে চান, তাহলে আপনি এই নির্দেশিকায় পরে সংশ্লিষ্ট বিষয়বস্তু দেখতে পারেন। আপনি যদি সময়ের জন্য চাপ দেন তবে আপনি এই গাইডের বিশদ বিবরণ ডাউনলোড করতে এখানে ক্লিক করতে পারেন বায়ুচাপ সেন্সর পণ্য পিডিএফ ডেটা.

অন্যান্য সেন্সর প্রযুক্তি সম্পর্কে আরও তথ্যের জন্য, অনুগ্রহ করে আমাদের সেন্সর পৃষ্ঠা দেখুন.