- দ্বারা WFsensors

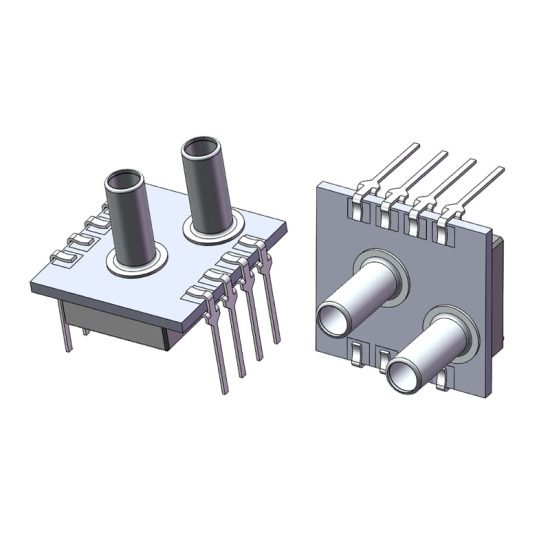

At the heart of airflow monitoring pressure sensors is a MEMS sensing element that converts tiny differential or absolute pressures into electrical signals, enabling real-time tracking of airway dynamics. Typical devices embed an ASIC to amplify, linearise and temperature-compensate signals, keeping total error near 0.5% FS across −40 to 85 °C. The 5V single-supply design with a 0.5–4.5V output plugs straight into common MCUs/ADCs. These parts are made for through-hole PCB mounting, with mechanical and electrical interfaces geared for quick swap-out and volume assembly.

ক্যাটালগ

1. How airflow monitoring pressure sensors work

Airflow monitoring pressure sensors usually use a MEMS absolute or differential diaphragm to turn tiny pressure swings into voltage. The sensor element’s design sets baseline noise and linear range, while the downstream signal-conditioning ASIC offers low-noise amplification, offset correction and temperature compensation. In top-tier devices the signal chain is carefully laid out to cut parasitic oscillation, shrink thermal drift and keep linearity tight, so you still get steady digital readings when airway pressure jumps about. For real-time airway work you must nail two things: the sensing element’s resolution and noise floor, and the signal-conditioning bandwidth and dynamic response. Practically, systems pick a 5V supply and a 0.5–4.5V proportional output so the signal can be fed directly into a fast ADC. The physical interface — think through-hole tubes — makes gas connections easy and mechanically solid, which reduces assembly-induced measurement error. Bottom line: the MEMS structure and ASIC must play nicely together for reliable real-world airway monitoring.

1.1 Sensing element and signal-conditioning chip

Sensing elements are typically microstructured diaphragms in rugged packages; the diaphragm’s mechanical constants drive sensitivity and range. A dedicated ASIC handles front-end gain and linearisation, then applies temperature compensation via internal algorithms to give a stable output. Smart packaging and micro-flow routing help cut gas trapping and stray-pressure artefacts.

2. Real-time flow sampling

Real-time airway pressure monitoring calls for sensors with adequate sampling rate and bandwidth. High-sample sensors catch brief shocks and cyclical wiggles in the airway that a low-sample setup would miss or mis-phase. Design reviews should inspect the sensor’s −3 dB bandwidth, any phase lag introduced by sensor-plus-amplifier, and the ADC sampling rate and anti-alias filtering downstream. A system meant for real-time control typically aims for end-to-end latency under one-third of the sampling period and no noticeable waveform distortion. Noise density and zero drift affect long-term monitoring reliability too, so pick sensors with low noise floor and built-in temperature compensation. During prototyping, run both frequency-domain and time-domain tests so you know the system reliably captures the signature features of your target breathing waveforms.

2.1 Sampling rate, bandwidth and system response

Matching sampling rate to bandwidth determines whether you reconstruct airway waveforms faithfully. For prototypes, aim to sample at least three times the target band and design sensible hardware filtering to balance real-time needs and interference rejection.

3. Temperature and environmental countermeasures

Temperature shifts change diaphragm mechanics and electronics behaviour, which skews readings. High-quality temperature-compensated sensors use programmable compensation tables or algorithms to hold total error to around 0.5% FS across −40 to 85 °C. This typically relies on ASIC-based multi-point linearisation and TCO correction, with factory calibration applied. In system design watch two things: that the device’s compensation range matches your operating temperatures, and that system thermal coupling (PCB heating, enclosure conduction) doesn’t add extra bias. In medical or respirator gear, humidity and temperature swings can be big, so add software self-checks and calibration cycles to keep long-term stability in check.

3.1 Programmable temperature compensation and ASIC implementation

Programmable compensation lets you tweak individual parts after manufacture to offset package variation or peculiar site conditions. Inside the ASIC you’ll usually see a temperature measurement channel, a compensation LUT and interpolation logic that corrects raw readings on the fly.

4. System integration and PCB assembly practice

This sensor family is made for through-hole PCB assembly, letting you solder quickly while keeping mechanical strength and gas tightness. The 5V single-supply design simplifies power rails, but on the PCB you still need clear analog/digital ground separation: amplifier and ADC return paths should be short and chunky to limit noise. The 0.5–4.5V proportional output shouldn’t be run long and unshielded, or it’ll pick up interference. Mechanically, tube diameter, hose fixings and sealing gaskets can induce static offsets, so include pressure-leak, mechanical-pressure and repeatability checks in assembly acceptance. In production run batch-consistency tests and track key parameters (zero, sensitivity, temperature drift) statistically to keep batches comparable.

4.1 5V single-supply and proportional output interface

These parts match common microcontroller input levels and the standardised output makes swapping between platforms easier. Still, engineering teams should validate output drive vs ADC input impedance — add a buffer amp or anti-interference filter at the front end if needed.

5. Applications and reliability validation

Airflow monitoring pressure sensors are widely used in HVAC, medical devices, respirators, process control and pneumatic control. In respirators, real-time airway pressure gives breathing curves, trigger decisions and safety cutoffs. To secure system reliability, validation must cover static accuracy, dynamic response, long-term drift, thermal cycling and vibration. For medical use, compliance tests (EMC, ESD resilience, etc.) are mandatory. Don’t just bench-test in ideal conditions — stress the system under realistic conditions including humidity swings, actual breathing rhythms and real-world tubing connections so the sensor holds up in the field.

5.1 Performance checks in medical, respirator and industrial control contexts

System-level testing is all about end-to-end reliability: gas inlet, sensor acquisition, control logic and alarm handling should be protocol-tested so you know how the device behaves under fault conditions and where the safety margins lie.

উপসংহার

Seen from the perspective of real-time airway pressure monitoring, the strength of an airflow monitoring pressure sensor lies in marrying a MEMS sensing element with solid ASIC signal-conditioning to deliver low noise, high accuracy and temperature compensation. In practice, watching sampling rate and bandwidth, matching temperature compensation range, confirming 5V supply and proportional output compatibility, and getting through-hole PCB assembly details right are the pillars of system stability. With methodical system-level validation you can rely on these sensors to keep delivering trustworthy airway pressure data in HVAC, medical and industrial settings.

উপরের ভূমিকাটি শুধুমাত্র চাপ সেন্সর প্রযুক্তির প্রয়োগের পৃষ্ঠকে স্ক্র্যাচ করে। আমরা বিভিন্ন পণ্যে ব্যবহৃত বিভিন্ন ধরণের সেন্সর উপাদান, তারা কীভাবে কাজ করে এবং তাদের সুবিধা এবং অসুবিধাগুলি অন্বেষণ করতে থাকব। এখানে কি আলোচনা করা হয়েছে সে সম্পর্কে আপনি যদি আরও বিশদ জানতে চান, তাহলে আপনি এই নির্দেশিকায় পরে সংশ্লিষ্ট বিষয়বস্তু দেখতে পারেন। আপনি যদি সময়ের জন্য চাপ দেন তবে আপনি এই গাইডের বিশদ বিবরণ ডাউনলোড করতে এখানে ক্লিক করতে পারেন বায়ুচাপ সেন্সর পণ্য পিডিএফ ডেটা.

অন্যান্য সেন্সর প্রযুক্তি সম্পর্কে আরও তথ্যের জন্য, অনুগ্রহ করে আমাদের সেন্সর পৃষ্ঠা দেখুন.