Catalog

MEMS (Microelectromechanical Systems) sensors in wearable devices are redefining how we interact with technology. These miniaturized sensors provide unprecedented accuracy and reliability for smartwatches, fitness trackers, and medical monitoring devices through integrated pressure, temperature, and barometric detection capabilities. This article analyzes the core design principles of MEMS sensors, focusing on their technical advantages in wearable applications, including ultra-low power design, high-precision measurement capabilities, and excellent environmental adaptability.

Fundamental Architecture of MEMS Sensors in Wearable Devices

Technical Breakthroughs in Miniaturized Packaging Design

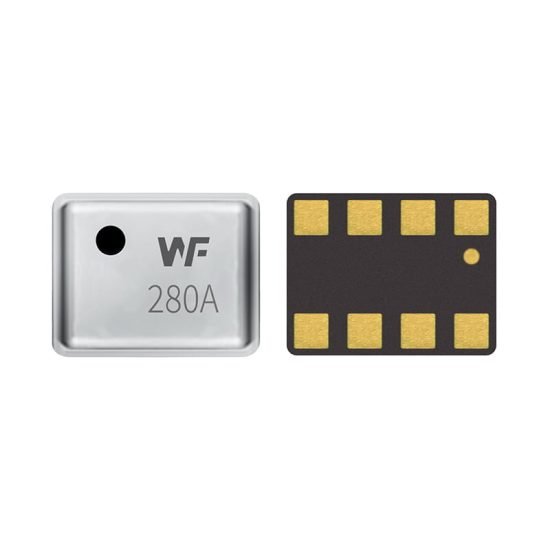

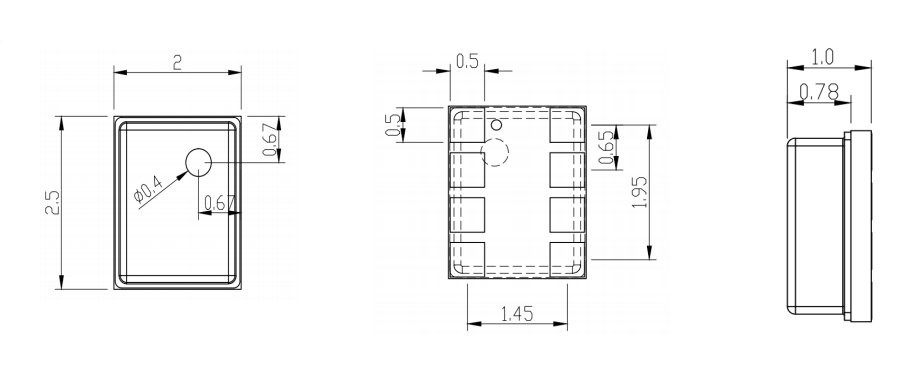

Modern wearable devices have extremely strict requirements for sensor dimensions. MEMS pressure sensors achieve millimeter-scale packaging through advanced silicon-based micromachining technology. Taking the WF280A as an example, its compact metallic packaging not only ensures mechanical strength but more importantly achieves excellent sealing performance. The standardized configuration of eight gold-plated contact points ensures signal transmission stability while maximizing PCB space efficiency. This design allows sensors to integrate easily into wearable devices with thicknesses of just a few millimeters without affecting user comfort.

Core Advantages of Resistive MEMS Technology

Resistive MEMS sensors use the piezoresistive effect principle, detecting pressure through resistance value changes in silicon materials under stress. This technology path offers lower temperature drift and higher long-term stability compared to capacitive sensors. In wearable applications, resistive design is particularly suitable for scenarios requiring long-term continuous monitoring, such as blood pressure monitoring and altitude measurement. The internal strain gauges are manufactured from single-crystal silicon, ensuring excellent linearity and repeatability, which is crucial for medical-grade wearable devices requiring precise physiological parameter monitoring.

Integrated ASIC Design Philosophy

Modern MEMS sensors integrate analog front-end, digital signal processing, and temperature compensation functions in a single ASIC chip. This integrated design not only significantly reduces system power consumption but also substantially improves measurement accuracy. The built-in temperature sensor can monitor environmental temperature changes in real-time and automatically correct pressure readings through preset compensation algorithms. This design enables sensors to maintain stable performance across a wide temperature range from -40°C to +125°C, meeting wearable device usage requirements under various environmental conditions.

Ultra-Low Power Design and Energy Efficiency Optimization

Innovative Power Management Strategies

Battery capacity limitations in wearable devices make power management a core challenge in MEMS sensor design. Advanced MEMS pressure sensors employ multi-level power management strategies including sleep mode, intermittent sampling, and dynamic frequency adjustment. In sleep mode, sensor power consumption drops to nanoampere levels, while in normal operation mode, typical consumption is only a few microamperes. This design enables sensors to operate continuously for days or even weeks in devices like smartwatches without significantly affecting battery life.

Low-Noise Signal Processing Technology

Low-noise design forms the foundation for high-precision measurements. MEMS sensors employ differential signal processing architecture, effectively suppressing common-mode and power supply noise interference. Built-in low-noise amplifiers and high-resolution ADCs ensure signal chain integrity. At 1Hz bandwidth, quality MEMS sensors achieve noise density below 0.1Pa, enabling detection of minute pressure changes such as respiratory-induced chest cavity pressure fluctuations or vascular pulse pressure variations.

Balanced Optimization of Sampling Rate and Resolution

Wearable applications require finding optimal balance between sampling rate and power consumption. MEMS sensors support programmable sampling rates from 1Hz to several hundred Hz, allowing engineers to optimize based on specific application requirements. For blood pressure monitoring applications, 10-50Hz sampling rates sufficiently capture pulse waveforms, while for altitude measurement, 1Hz sampling rates meet requirements. High-resolution ADCs (typically 16-24 bits) ensure excellent measurement accuracy even at low sampling rates.

High-Precision Measurement and Environmental Adaptability

Technical Assurance for Pressure Measurement Accuracy

MEMS sensor pressure measurement accuracy directly affects wearable device functionality. Modern sensors achieve ±0.1%FS accuracy levels across full temperature ranges through multi-point temperature compensation and nonlinear correction algorithms. This accuracy enables sensors to accurately measure altitude changes (meter-level precision) and minute physiological pressure variations. Sensor long-term stability is equally important, with quality products maintaining ±0.02%FS drift levels within one year, ensuring long-term reliability.

Intelligent Implementation of Temperature Compensation Algorithms

Temperature effects on MEMS sensor performance cannot be ignored. Advanced sensors integrate high-precision temperature sensors within ASICs and employ polynomial temperature compensation algorithms. This compensation not only corrects temperature effects on sensitivity but also calibrates zero drift and nonlinear errors. Real-time temperature compensation enables sensors to maintain stable measurement performance under conditions like body temperature changes and environmental temperature fluctuations, particularly important for outdoor sports monitoring and medical care applications.

Response Speed and Dynamic Performance

Fast response requirements in wearable applications demand excellent dynamic performance from MEMS sensors. Modern sensors typically have millisecond-level response times, enabling rapid pressure change tracking. This fast response capability allows sensors to accurately capture pulse waveform detail features, providing reliable data foundation for heart rate variability analysis and blood pressure estimation. Optimized mechanical design ensures stable performance under vibration and shock environments.

Performance Advantages and Adaptability

Durability Design and Protection Rating

Wearable devices face complex and variable usage environments, requiring MEMS sensors to possess excellent durability. Advanced packaging technology employs glass welding or metal sealing processes, achieving IP67 or even IP68-level waterproof and dustproof performance. This protection level enables sensors to operate normally in water-involved environments like swimming and bathing. Additionally, sensors must withstand mechanical shocks and vibrations from daily wear, with optimized structural design ensuring reliability under 10,000g shock and 20g vibration conditions.

Wide-Range Measurement Capability

Modern MEMS sensors support broad pressure measurement ranges, with typical products measuring absolute pressures from 0.3kPa to 1100kPa (equivalent to 11Bar). This wide-range capability enables single sensors to simultaneously support barometric functions (for altitude measurement) and blood pressure monitoring functions. Sensors maintain linear response across full range, simplifying signal processing algorithm complexity. Support for multiple pressure reference types (absolute pressure, gauge pressure, differential pressure) enables sensor adaptation to different application scenarios.

Measurement Media Diversity Adaptation

MEMS sensors are designed considering compatibility with various measurement media, including air, nitrogen, and other inert gases. This media compatibility enables sensors to function not only in atmospheric pressure measurement but also in medical devices like inflatable blood pressure cuffs and ventilators. Sensor chemical stability design ensures performance stability under long-term exposure to different gas environments, crucial for medical-grade application safety.

Measurement Tools and Precision Verification Methods

Professional Calibration Equipment Selection Standards

Verifying MEMS sensor performance requires high-precision reference standard equipment. Digital pressure calibrators like the Fluke 718 series provide 0.025% reading accuracy pressure references, ideal tools for verifying sensor linearity and accuracy. Temperature compensation performance verification requires coordination with temperature control chambers and high-precision thermometers. Calibration processes typically occur in constant temperature and humidity environments to ensure test result repeatability and reliability.

Dynamic Performance Testing Methods

Sensor dynamic response characteristics require verification through specialized test equipment. Fast pressure change generators can produce step, sinusoidal, and random pressure signals for testing sensor frequency response and phase characteristics. Oscilloscopes and spectrum analyzers record and analyze sensor output signals, evaluating noise performance and bandwidth characteristics. These tests are crucial for ensuring sensor performance in actual applications.

Long-Term Stability Assessment

MEMS sensor long-term stability assessment requires months or even years of continuous monitoring in controlled environments. Automated test systems can regularly perform calibration point checks, recording sensor output drift trends. Temperature cycling tests and mechanical shock tests evaluate sensor reliability under harsh environments. This test data provides scientific basis for sensor service life prediction and maintenance strategy development.

Conclusion

MEMS sensor technology applications in wearable devices represent an important direction in sensor technology development. Through perfect combination of miniaturized packaging, ultra-low power design, and high-precision measurement capabilities, modern MEMS sensors provide powerful sensing capabilities for wearable devices. Resistive MEMS technology combined with intelligent temperature compensation algorithms ensures stable sensor performance under various environmental conditions.

From a technical perspective, integrated ASIC design significantly enhances overall system performance, while wide-range measurement capability and excellent environmental adaptability enable single sensors to support multiple application scenarios. Professional measurement tools and rigorous verification methods guarantee sensor product quality and reliability.

As the wearable device market continues growing, MEMS sensor technology will continue developing toward higher precision, lower power consumption, and stronger adaptability, providing users with more intelligent and convenient life experiences.

The above introduction only scratches the surface of the applications of pressure sensor technology. We will continue to explore the different types of sensor elements used in various products, how they work, and their advantages and disadvantages. If you’d like more detail on what’s discussed here, you can check out the related content later in this guide. If you are pressed for time, you can also click here to download the details of this guides air pressure sensor product PDF data.

For more information on other sensor technologies, please visit our sensors page.