- By WFsensors

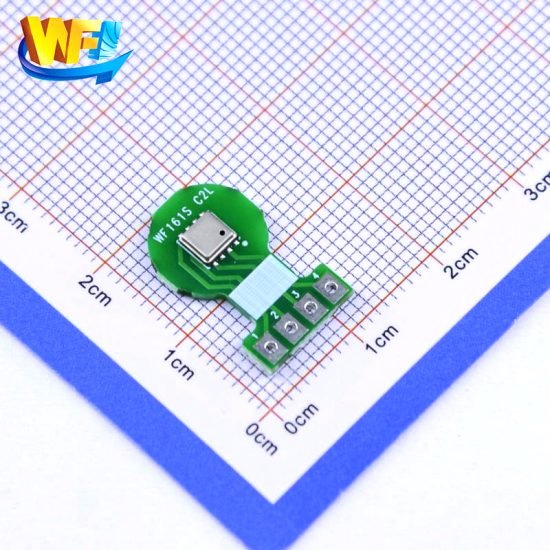

Modern tyre-pressure monitoring splits into two practical routes: external valve-cap style units and in-tyre units. Each has different trade-offs in sensor construction, power management, sampling rate and data completeness. Drawing on practical experience with MEMS absolute-pressure devices and system integration, this article gives actionable technical points and selection advice, and points out engineering considerations based on the pictured sensor form factor.

Catalog

1. System architecture and data-link design

The heart of a tyre-pressure monitoring system is reliable pressure sampling and dependable data reporting. Each hop — sensor, gateway, cloud — affects the usability and latency of the reading. At the sensor end you need high sensitivity absolute-pressure measurement, linearised output and temperature compensation; these directly affect the precision once you convert to user units (for example, PSI). Equally important is having built-in ADC and simple calibration parameters to minimise external circuit complexity, which lowers whole-system cost and maintenance overhead. For fleet use, continuous pressure checks mean the module must support low-power modes and wake on schedule for accurate single measurements, while caching locally during brief comms outages. On the cloud side, bulk data handling, anomaly detection and alarm thresholds must be in place so operations staff can act quickly.

1.1 From sensor layer to cloud: data capture and relays

At the sensing layer, favour devices with internal wake timers and low-noise front ends so small pressure changes are still detected. A relay or gateway aggregates multiple wheel nodes and performs secondary checks like filtering and timestamp alignment. Low-power wireless protocols with retransmit schemes balance energy use and reliability. When deploying, watch for antenna orientation, metal obstructions and vibration-induced packet loss; local redundant caching and tuned retransmit logic significantly improve system robustness.

2. External quick-fit solution and on-site deployment

For rapid fleet rollouts, replaceable valve-cap style external units are ideal. The design must ensure mechanical fit and sealing so vibration or water ingress doesn’t degrade performance. The key benefit is minimal downtime: no tyre removal is required, so large fleets can be retrofitted quickly. From an engineering standpoint you must check threading compatibility, seal material and anti-theft measures, and make sure the sensor’s access to the tyre’s internal air is unobstructed so it reflects true pressure. If you later plan to switch to in-tyre sensors, the valve-cap unit serves as a temporary monitor during tyre swaps, keeping readouts continuous until permanent sensors are fitted.

2.1 Rapid retrofit with minimal downtime

Deploy in staged batches to validate fit across vehicle types. Standardise the installation procedure so crews can outfit a wheel in minutes. Supply calibration tools and spare cells (if applicable), and log unit IDs to vehicle records for traceable maintenance and fault tracking.

3. In-tyre sensor unit technology

Mounting the sensor inside the tyre gives richer data: pressure plus temperature and estimations of tyre mileage. An in-tyre node typically integrates a microcontroller, a MEMS pressure chip and a wireless transceiver with a few passive parts to form a complete TPMS unit. The crux is a low-power architecture: accurate wake timers, fault-tolerant measurement flow and local processing to avoid excessive broadcasting. Choose MEMS devices that show long-term stability and use moisture-resistant packaging to survive the tyre’s temperature, humidity and shock environment.

3.1 Integrated microcontroller and low-power wake strategy

Sampling usually mixes scheduled checks with event-driven bursts: long intervals for routine reads, high-rate sampling when a rapid drop or sharp temp rise occurs. On-chip interval timers and a low-frequency receiver enable on-demand wake, preserving battery life. Firmware should implement adaptive sampling and local anomaly logic to cut false alarms and reduce bandwidth use.

4. Low-power remote transmission

Wireless choice and power strategy drive maintenance cost and system responsiveness. For fleets, a design that uses a sensitive low-frequency receiver together with short, higher-power transmissions is often best: it keeps receive sensitivity high while limiting transmit duty to save energy. Anti-interference needs attention at antenna matching, EMC design and protocol-level retransmit logic. Battery choices lean to high-energy-density primary cells or hybrid rechargeable setups; for long life you must push sleep current down to sub-microamp levels.

4.1 Low-frequency reception, wake-up and signal robustness

Low-frequency receivers tend to do better in weak-signal scenarios. Combine this with interference detection and filtering to improve wake accuracy. To counter vehicle electrical noise use differential signal routing, good ground-plane layout and both hardware and software filtering. The system should adapt transmit power based on RSSI or link quality to keep connectivity while saving energy.

5. Unit conversion and display strategy (multi-unit pressure conversion (PSI/kPa/bar/kg/cm²))

To suit different markets and user habits, the sensor module or gateway must support multi-unit pressure conversion and display. A clean approach is for the sensor to output a standardised raw quantity (calibrated voltage or digital count) and let the gateway or backend do the unit conversion and rounding. The catch is preserving precision at every step: sensor linearisation and temperature compensation must be reliable inputs, and gateway software must keep relevant decimal places and pass unit metadata.

5.1 Support for four conversion units and calibration methods

Support PSI, kPa, bar and kg/cm² with one-click switching in the UI. For accuracy, combine factory temperature and linearisation calibration with a simple field zero or point-calibration at a known pressure to remove installation offsets. Keep calibration version and timestamp in logs for audit and traceability.

Conclusion

From a systems viewpoint, a good tyre-pressure sensor balances accuracy, power use, deployability and data-link reliability. For fleet work the quick-fit valve-cap keeps downtime low, while in-tyre units deliver richer data. In making a choice pay attention to MEMS linearity and temperature compensation, low-power wake features, wireless robustness and a clear multi-unit calibration strategy. The goal is to get reliable, actionable tyre data with minimal operating cost so engineers and decision-makers can choose the right set-up.

The above introduction only scratches the surface of the applications of pressure sensor technology. We will continue to explore the different types of sensor elements used in various products, how they work, and their advantages and disadvantages. If you’d like more detail on what’s discussed here, you can check out the related content later in this guide. If you are pressed for time, you can also click here to download the details of this guides air pressure sensor product PDF data.

For more information on other sensor technologies, please visit our sensors page.