The field of pressure measurement encompasses a myriad of variables, from chemical laboratories equipped with highly calibrated sensors that measure gases down to the nanometer scale, to large factories that track fluctuations in industrial levels, allowing us to predictably control these daily conditions. Pressure measurement is an essential part of ensuring safe operation in our working and living environments.

In this article we will explore some aspects of pressure measurement technology, touching on pressure measurement units, methods, main components and instruments.

Here’s the summary:

- أساسيات قياس الضغط والضغط

- كيفية قياس الضغط

- وحدات قياس الضغط والتحويلات

- تصنيف أجهزة قياس الضغط

- خاتمة

Let’s go!

أساسيات قياس الضغط والضغط

What is Pressure?

Pressure is a physical quantity that measures the amount of force exerted on an object per unit area. This physical quantity can be generated in different ways, including applying a force to an object or increasing the temperature or density of the surrounding environment. Gravity, air pressure, and other factors can also cause pressure to increase.

How is Pressure Expressed?

You can measure pressure in various units, such as pounds per square inch (psi) or pascals (Pa). This depends on the pressure measuring system used. Each pressure unit measurement represents a different force per unit area, helping to measure pressure in different environments. For example, psi is commonly used to measure tire pressure, while mmHg is commonly used in medicine to measure blood pressure.

What are the three types of stress?

The three pressure types are: absolute pressure, gauge pressure and differential pressure

- Absolute Pressure: This is the total pressure exerted by the fluid, including atmospheric pressure. It is measured relative to a perfect vacuum.

- Gauge Pressure: This is the difference between absolute pressure and atmospheric pressure. The pressure of a fluid relative to the environment is often measured in engineering applications.

- Pressure Differential: This is the difference in pressure between two points in a system. It can be used to measure flow, filter status and other variables in industrial processes.

كيفية قياس الضغط

قياس الضغط

1. Absolute pressure measurement

Absolute pressure measurement is a method of measuring the total pressure of a system, including atmospheric pressure. This type of measurement starts at 0 Pa and can measure pressure up to atmospheric pressure and vacuum levels.

Paa (pascals absolute) and psia (pounds per square inch absolute) are units commonly used to express absolute pressure. Absolute measurements are important when studying changes in total pressure because they measure the full effect of the atmosphere and the forces exerted on an object or area.

2.Gauge Pressure Measurement

Gauge pressure measurement is a type of measurement used to quantify a system in relation to atmospheric pressure measurement, meaning that it excludes the effect of atmospheric pressure. This type of pressure measurement is commonly used in situations such as tire and blood pressure measurements, where an accurate measurement of the amount of force exerted on an area is critical to safety.

Gauge pressure values can be expressed in units such as pascals (Pag) or pounds per square inch (psig), depending on the specific requirements of the situation. The use of gauge pressure can help to more accurately understand how much force is being applied to an area because it eliminates the effects of atmospheric pressure fluctuations from the calculation.

3.Differential Pressure Measurement

Differential pressure measurement is a process used to measure and control the pressure difference between two points. This type of measurement is commonly used in a variety of applications such as fuel tanks, air compressor systems and fluid transfer systems. It helps to maintain the relative pressure between two points so that it does not exceed a safe level for operation.

Differential pressure is usually measured in terms of Pad (pascals) or psid (pounds per square inch).

Translated with DeepL.com (free version)

What is the most common pressure measurement?

The most common pressure measurement is gauge pressure. In engineering and industrial applications, gauge pressure is often used to determine the pressure of a fluid compared to atmospheric pressure. Measurements are usually made using devices such as Bourdon tubes, diaphragm gauges and strain gauges.

It is worth mentioning that depending on the specific application and needs, various pressure measurements are also available, such as absolute and differential pressure.

What are the different ways to measure pressure?

There are many ways to measure pressure, including:

Mechanical Pressure Gauge: These pressure gauges use mechanical components such as Bourdon tubes, diaphragms, or bellows to measure pressure and display it through a pointer on a dial.

Electrical sensors: They convert pressure into electrical signals that can be measured with instruments such as voltmeters or oscilloscopes.

Vacuum Gauge: Usually combines mechanical and electrical methods to measure the difference between atmospheric pressure and vacuum pressure.

Manometer: Measures pressure by comparing the height of a column of liquid in a U-shaped tube.

Piezoresistive sensors: They use changes in electrical resistance to measure deformation caused by applied stress or force.

Capacitive Sensors: These sensors use changes in capacitance to measure deformation caused by applied stress or force.

Optical sensors: use light to detect deformation caused by changes in pressure.

The choice of technology depends on factors such as the required accuracy, measurement range, and measurement environment.

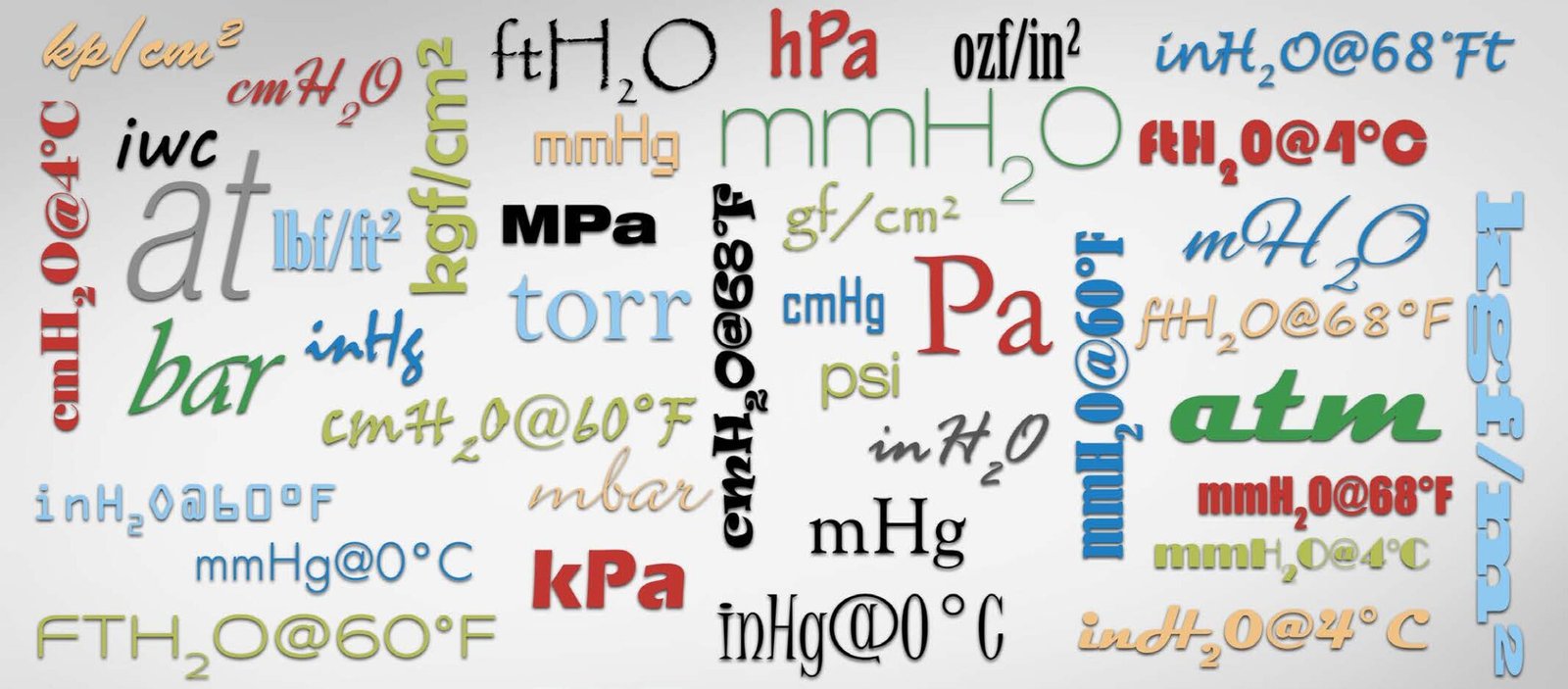

وحدات قياس الضغط والتحويلات

What is the unit of pressure?

Pascal (Pa): This is the SI unit of pressure, named after the French mathematician Blaise Pascal. 1 Pa is equal to 1 Newton per square meter.

Kilopascal (kPa): 1 kilopascal is equal to 1000 pascals, which is equivalent to a force of 1000 newtons on an area of 1 square meter.

Pounds per square inch (psi): PSI is an imperial unit commonly used in the United States and other countries that do not use metric pressure units. It measures the amount of force exerted on an area of one square inch.

Bar: The bar is a non-SI pressure unit commonly used in meteorological and industrial applications. 1 bar is equal to 100,000 pascals.

Atmosphere (atm): The atmosphere is a unit of pressure approximately equal to the Earth’s mean atmospheric pressure at sea level, approximately 101,325 Pa or 14.7 psi.

Torr: Torr is a unit of pressure commonly used in vacuum measurements, named after Italian physicist Evangelista Torricelli. One Torr is equal to 1/760 of standard atmospheric pressure at sea level.

Millimeters of mercury (mmHg): A pressure unit commonly used in medicine as a unit of blood pressure measurement and also in vacuum technology as an alternative to Torr.

ما هي الوحدات الشائعة للضغط & their conversions?

- Pascal (Pa)

- Kilopascal (kPa)

- bar (bar)

- Pounds per square inch (psi)

- Millimeters of mercury (mmHg)

- Atmosphere (atmospheric pressure)

- ثور

جدول تحويل وحدة قياس الضغط

Here are some common pressure measurement units and their conversion tables:

Please note that these are approximate conversions and may differ slightly depending on the specific context or application. It is always important to use the correct units and conversion factors for your specific situation to ensure accurate measurements and calculations.

For more information on converting pressure measurement units, see تحويل وحدة الضغط.

تصنيف أجهزة قياس الضغط

What is a pressure instrument?

The variety of precision instruments are available for measuring pressure. Pressure sensors and pressure gauges are among the most commonly used instruments in many applications.

Pressure sensors measure the pressure of a gas or liquid using a strain gauge mounted on a diaphragm. Strain gauges measure the deformation of the diaphragm as it is acted upon by gravity, producing an electronic signal proportional to the applied pressure.

Pressure gauge uses a mechanical connection between an external source and a pointer to measure the pressure exerted by a medium. These instruments are capable of providing very accurate readings within their range and sensitivity requirements and can be tuned for different applications.

In addition, there are specialized instruments, such as pressure gauges that measure the difference in pressure between two points, and other instruments for measuring physical pressure, such as vacuum gauges for low pressure measurements or vacuum levels. The choice of instrument depends on the specific application and the requirements for measurement accuracy, range and sensitivity.

What are the two basic types of pressure measuring equipment?

Absolute pressure measuring devices: These devices measure pressure relative to a perfect vacuum, i.e. absolute zero pressure. Examples include absolute pressure sensors and barometers.

Gauge pressure measuring devices: These devices measure pressure relative to atmospheric pressure (i.e., the pressure exerted by the Earth’s atmosphere at sea level). Examples include Bourdon gauges, manometers and the most common pressure gauge.

In addition to these two basic types, there are also differential pressure measuring devices that measure the pressure difference between two points (e.g. flow measurement), as well as compound pressure measuring devices that can measure both gauge and absolute pressure.

خاتمة

Pressure measurement is an important part of many industrial and scientific processes. Accurate and reliable pressure measurement is essential to ensure the safe and efficient operation of machinery and to monitor and control various physical and chemical processes.

There are many types of pressure measurement equipment available, each with its own advantages and disadvantages. Instrument selection depends on factors such as range, accuracy requirements, environmental conditions, and cost. As technology continues to advance, we expect pressure measurement capabilities to continue to improve, which will enable us to address more complex challenges in the future.

What else would you like to know about pressure measurement? Or have some questions?

Either way, please leave a comment below or contact us.