With the development of automation technology, electric suction cups are more and more widely used in industrial production. The pressure sensor, as an important component of the electric suction cup, directly affects the stability and safety of the adsorption effect. The purpose of this paper is to analyze in detail the optimal role of pressure sensors in electric suction cups, and to help readers understand their applications in different fields and their technical characteristics.

Table of Contents

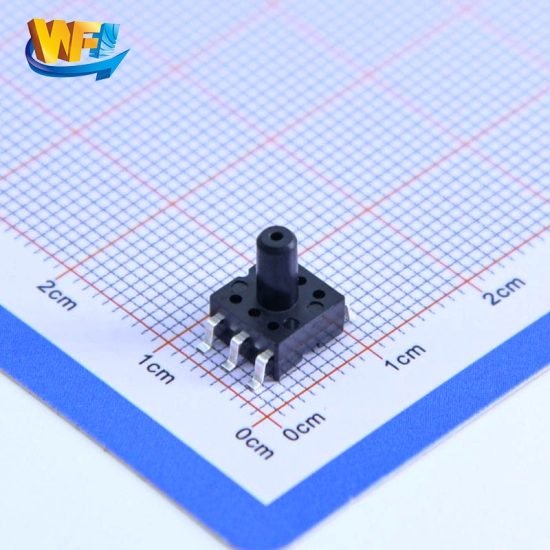

Basic Principles of Pressure Sensors

1. Types of sensors

There are two main types of pressure sensors used in electric suction cups: analog pressure sensors and vacuum sensors. Each type of sensor has its own unique principle of operation and scope of application.

2. Principle of operation

The operating principle of the pressure sensor is based on the measurement of pressure changes. When the electric suction cup is in operation, the change in adsorption force detected by the sensor is converted into a telecommunication signal, which is fed back to the control system for real-time adjustment.

Functional realization

1. Evacuation adsorption

One of the core advantages of electric suction cups is their evacuation function. The pressure sensor ensures that the suction force is maintained within the recommended range of 100kPa to 200kPa, thus ensuring the safety and stability of the object.

2. Real-time monitoring of suction pressure status

Through the pressure sensor, the electric suction cup can monitor the suction force status in real time to ensure that the device is in the best working condition. The monitoring data can help the control system to automatically adjust the suction force to improve work efficiency and safety.

3. Built-in Intelligent Sensor

The built-in smart sensor continuously monitors the vacuum status to ensure that the suction force is adjusted at any time during operation. This feature is essential to prevent items from slipping out, especially during high-speed transportation or maneuvering.

4. Automatic Pressurization and Recharge Function

The pressure sensor is capable of automatic pressure maintaining and air filling. By continuously monitoring the vacuum status, the system can automatically replenish the air when the suction force decreases, ensuring that the suction cups are always in the best suction condition.

5. Energy saving and noise reduction

Modern pressure sensors are also characterized by energy saving and noise reduction. By optimizing the control of suction force, unnecessary energy consumption can be reduced, and the noise level of the equipment during operation can be reduced, providing a more comfortable working environment for users.

Electric Suction Cup Sensor Solutions

Industry Applications

1.Packaging Industry

In the packaging industry, electric suction cup sensors are widely used in automated packaging lines to ensure safe product handling and packaging efficiency. Studies have shown that packaging lines using electric suction cups can significantly increase efficiency and reduce material waste.

2. Mechanical industry

In the machinery industry, electric suction cups are used to move heavy loads, and the precise control of pressure sensors significantly improves efficiency and safety. A case study shows that a machinery manufacturer has achieved a 40% improvement in material handling efficiency through the use of electric suction cup sensors.

3. Construction

In the construction industry, suction cup sensors are used to move heavy materials such as glass and marble, ensuring safety during lifting and placement. Studies have shown that proper suction control reduces the incidence of accidents.

4. Electronics

In the electronics industry, electric suction cup sensors are used to transport sensitive components to meet high environmental standards and ensure damage-free transportation. Data shows that the failure rate of electronics production lines with pressure sensors has been reduced by 30%.

Technical Details & Research

1. Data and Literature Support

Research has shown that the proper selection of pressure sensors can significantly improve adsorption efficiency. Literature suggests that by optimizing adsorption control, companies can effectively reduce energy consumption and improve overall production efficiency.

2. Case Study

After introducing vacuum sensors to a machinery manufacturing enterprise, the efficiency of material handling increased by 40%. The enterprise utilized the real-time monitoring function of the pressure sensor to effectively reduce equipment failures and production stoppages, and the analysis of specific data showed that its economic benefits were significant.

Conclusion

The role of pressure sensors in electric suction cups is not limited to the monitoring and regulation of suction force, but also provides a strong support for the automation and efficiency of enterprises. As technology develops, suction cup sensors will continue to evolve to meet the changing needs of industry.

References:

Zhang, Y., & Li, J. (2020). Advances in Vacuum Technology and Applications. Journal of Vacuum Science.

Wang, H., & Chen, S. (2021). Applications of Pressure Sensors in Industrial Automation. Sensors and Actuators.

Liu, T., & Yang, M. (2019). Pressure Measurement and Control in Industrial Applications. Measurement Science Review.